A Method for Determining Critical Speed of Wet Rotor in Multistage Centrifugal Pump

A critical speed and determination method technology, which is applied in special data processing applications, instruments, electrical digital data processing, etc., can solve the problem of lack of multi-stage centrifugal pump wet rotor guidance method and platform, long time from modeling to obtaining results, etc. Unable to promote the use and other problems, to achieve the effect of saving design cycle, high professional quality, and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] In order to make the objectives, technical solutions, and advantages of the present invention clearer, the following further describes the present invention in detail. It should be understood that the specific embodiments described here are only used to explain the present invention and not to limit the present invention.

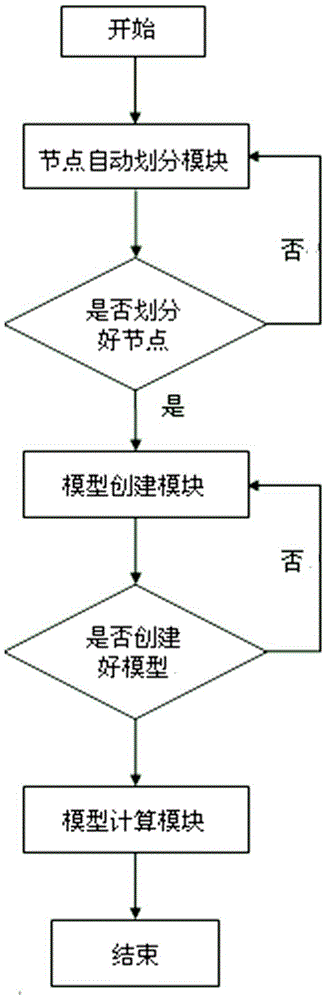

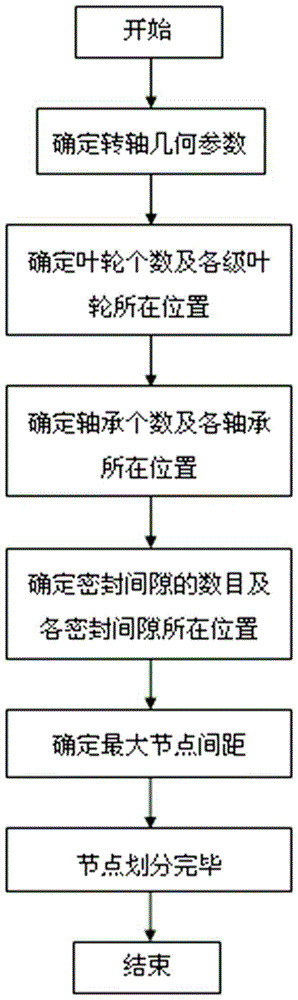

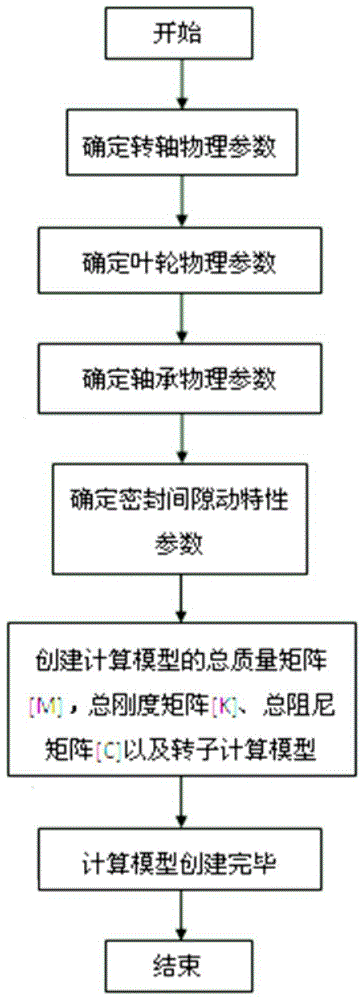

[0036] Such as figure 1 As shown, the method for determining the critical speed of the wet rotor of the multi-stage centrifugal pump according to the present invention mainly uses three modules: node automatic division module, model creation module, and model calculation module. Each module performs data processing in turn. First, the node automatically divides the modules. Complete the automatic division of the nodes of the entire rotor. After ensuring that the nodes are divided, enter the model creation module to complete the total mass matrix [M], total stiffness matrix [K], total damping matrix [C] and rotor calculation model in this module Finally,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com