Displayer

A display and display panel technology, which is applied in the direction of instruments, refractors, semiconductor devices of light-emitting elements, etc., can solve the problems of inability to realize narrow-frame displays, long light mixing distance, and prolonging process time, so as to save assembly time and process cost , Improve the uniformity of light mixing and reduce the effect of light mixing area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

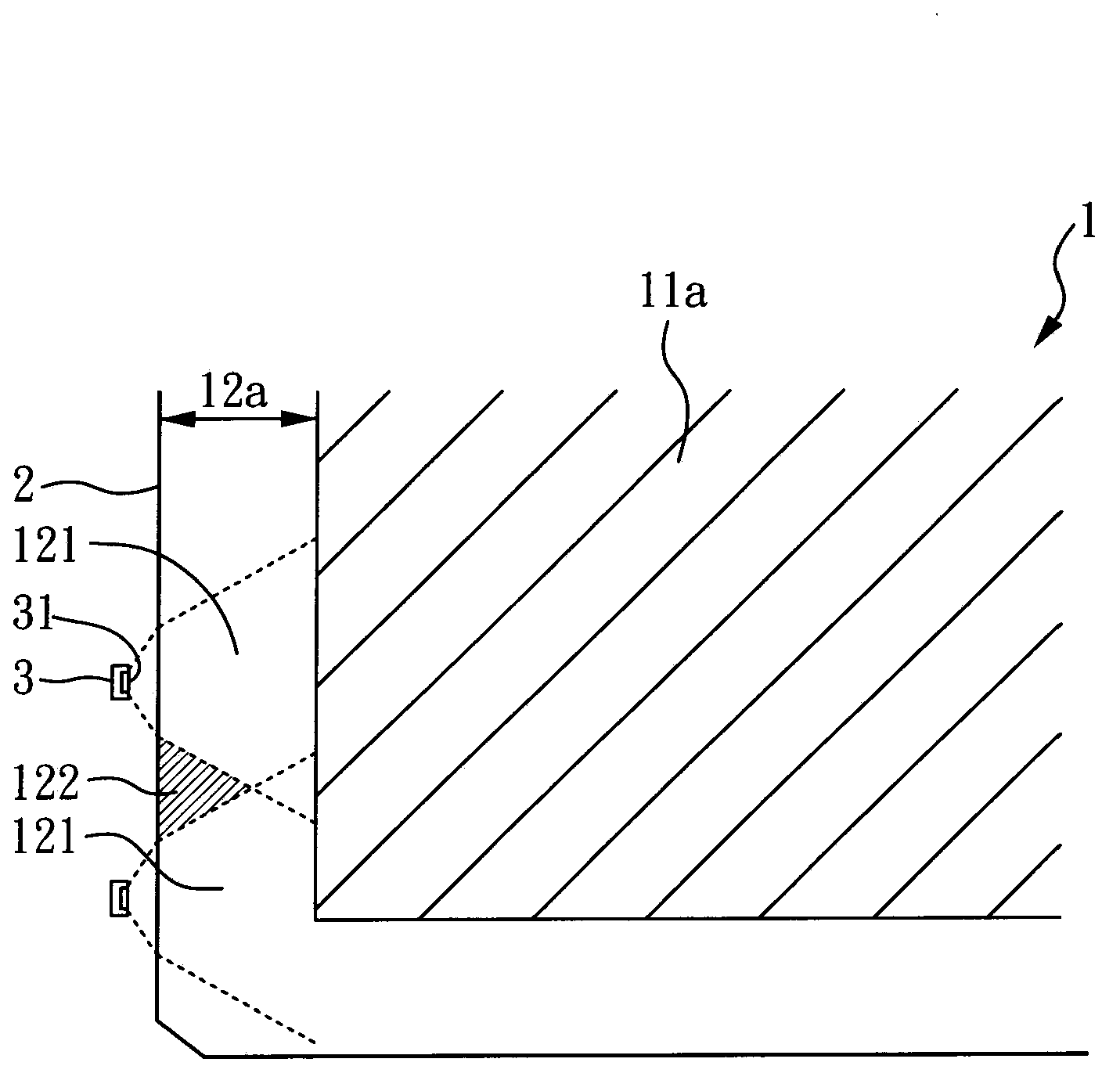

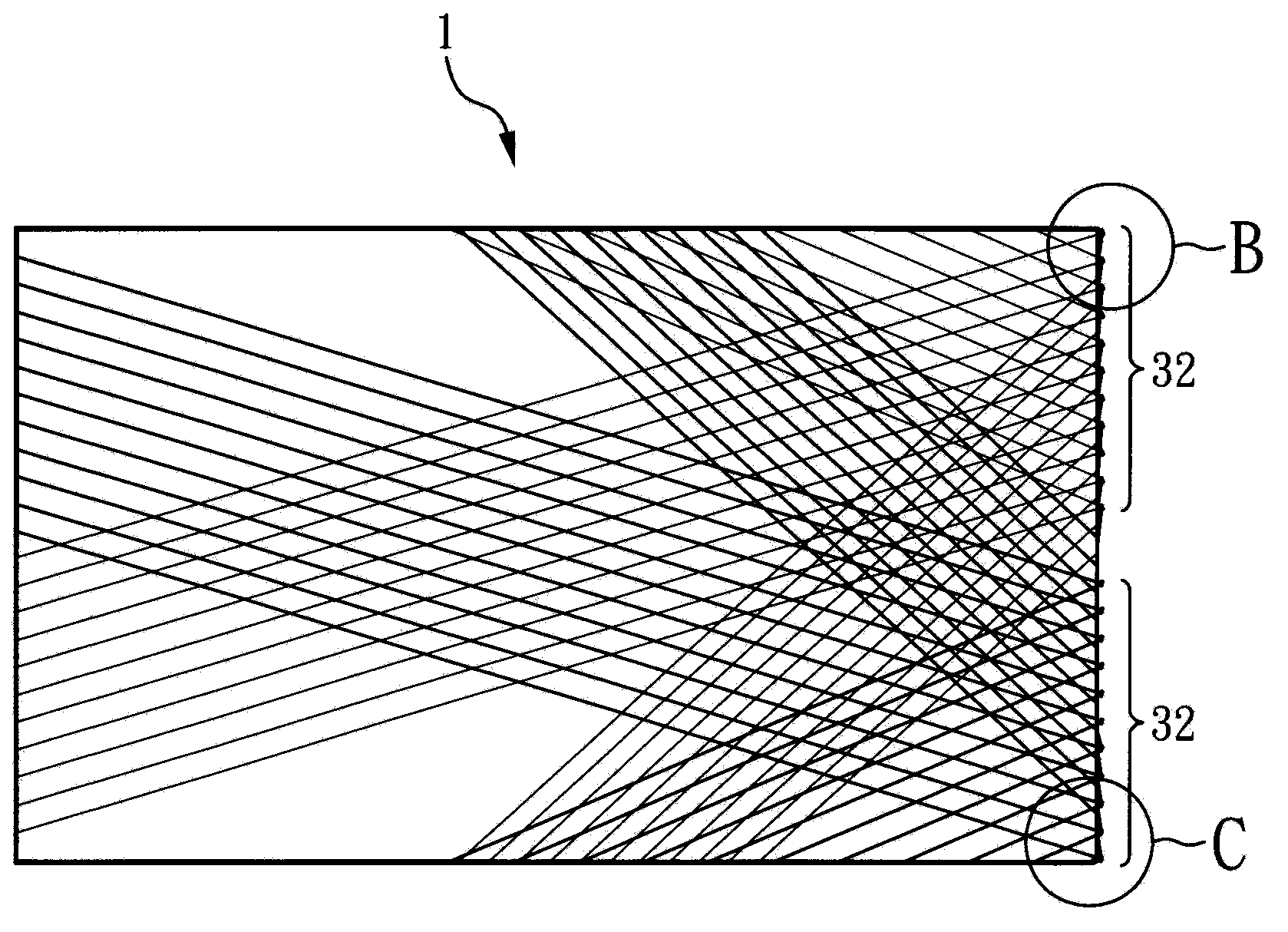

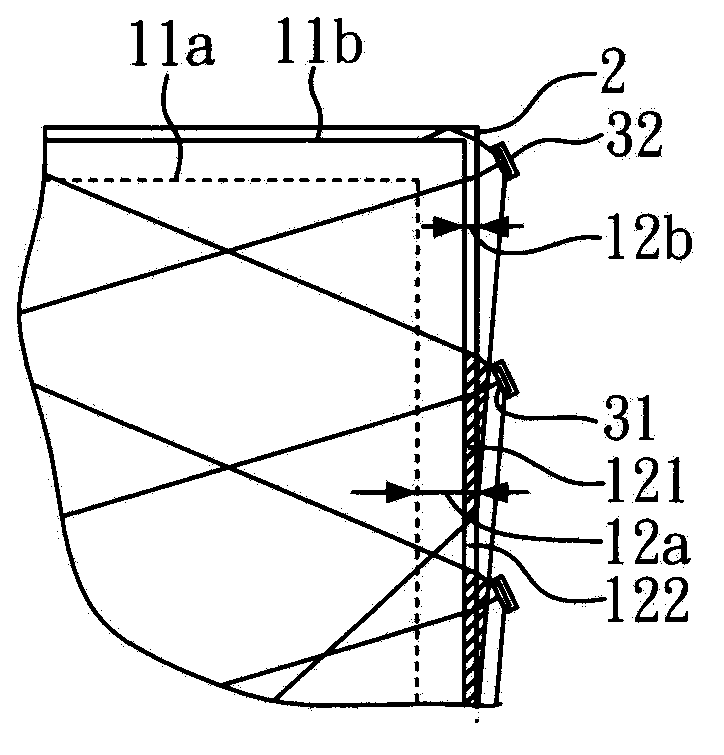

[0039] Figure 2A It is a schematic diagram of a display of an embodiment. This embodiment takes a 31.5" display as an example, but it is not limited thereto. Wherein, the display adopts a single short-side light incident mode, and the light-emitting diode is arranged on a light incident surface of the light guide plate. The light emitting surfaces of the light emitting diodes form an angle with the light incident surface of the light guide plate respectively, wherein the angle range is between 2 degrees and 60 degrees. In this embodiment, the light emitting diodes are divided into two groups, the first group: light emitting The light emitting surface 31 of the diode 32 and the light incident surface 2 of the light guide plate are both inclined downward at an angle of 25°, and the assembly position is relative to the upper right side of the display panel 1, as shown in Figure 2B As shown; the second group: the light emitting surface 31 of the light emitting diode 33 and the l...

Embodiment 2

[0042] Figure 3A It is a schematic diagram of a display. Wherein, the display adopts double-short-edge light-incident mode, and the light-emitting diodes are divided into two groups. The first group: the light-emitting surface 31 of the light-emitting diode 32 and the light-incoming surface 2 of the light guide plate are both inclined downward at an angle of 25°. Relative to the upper right side of display panel 1, such as Figure 3B As shown; the second group: the light emitting surface 31 of the light emitting diode 33 and the light incident surface 2 of the light guide plate are all at an upwardly inclined angle of 25°, and the group setting position is relative to the lower left side of the display panel 1, such as Figure 3C shown. The light emitting diodes 32 and 33 in the two groups are equidistant, and the light emitting surface 31 of the first group of light emitting diodes 32 and the light emitting surface 31 of the second group of light emitting diodes 33 form an...

Embodiment 3

[0045] Figure 4A It is a schematic diagram of a display. Among them, the display adopts a single long side light input mode, and the light-emitting diodes are divided into three groups. The first group: the light-emitting surface 31 of the light-emitting diode 32 and the light-incoming surface 2 of the light guide plate are at an angle of 25° inclined to the right. Relative to the lower right side of display panel 1, such as Figure 4B As shown; the second group: the light emitting surface 31 of the light emitting diode 33 and the light incident surface 2 of the light guide plate are all inclined to the left at an angle of 25°, and the group setting position is relative to the lower left side of the display panel 1, such as Figure 4D As shown; the third group: the light emitting surface 31 of the light emitting diode 34 is parallel to the light incident surface 2 of the light guide plate. Figure 4C shown. The light-emitting diodes 32, 33, and 34 in the three groups are a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com