A DC circuit breaker

A technology of DC circuit breakers and DC transmission lines, which is applied in circuits, circuit devices, high-voltage/high-current switches, etc., can solve the problems that the breaking time is difficult to meet the DC transmission system, and the current cannot be turned off, so as to achieve rapid topological breaking, The effect of protecting safety and reducing loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

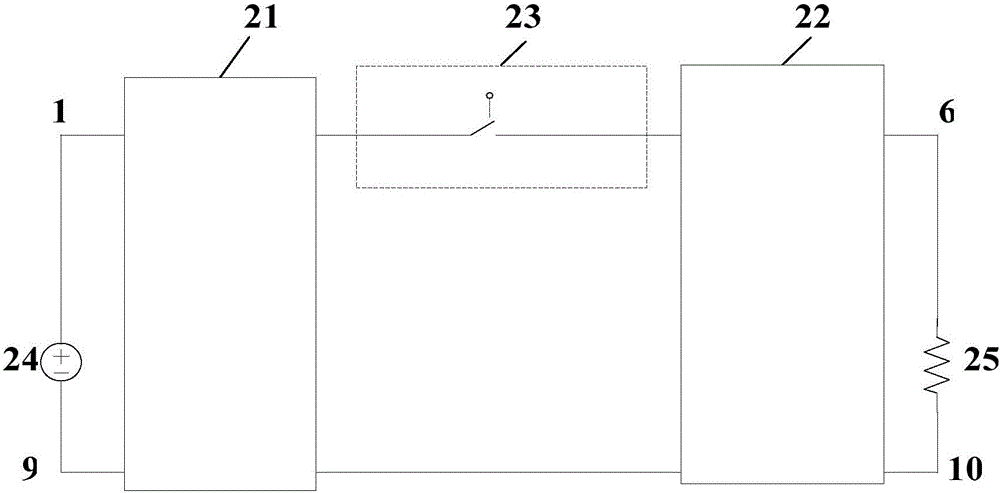

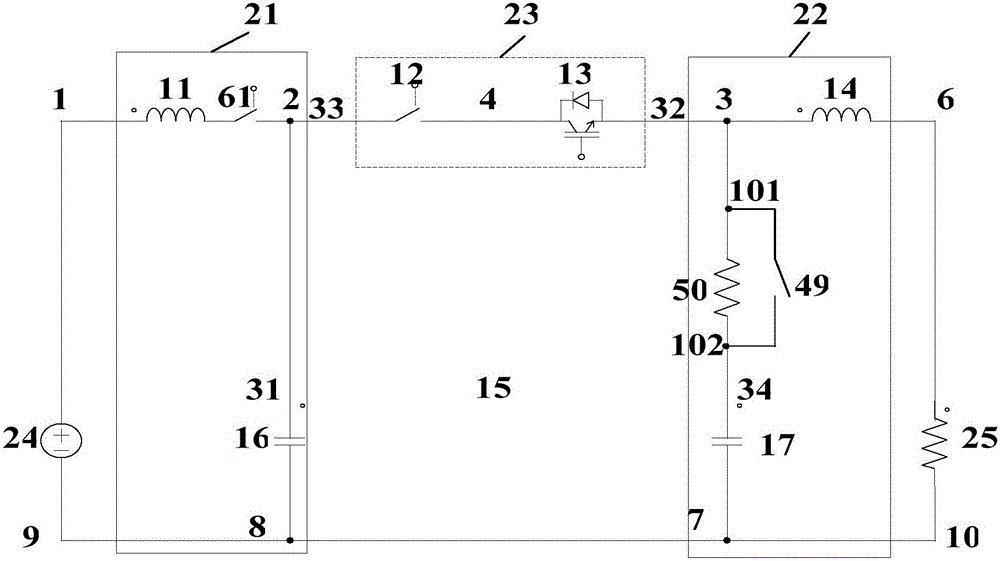

[0047] figure 2 Shown is Example 1 of the present invention. Such as figure 2 As shown, the DC power supply 24 is a converter station, and the resistor 25 is a short-circuit resistor. The basic structure of the DC breaking topology of the present invention includes: an initial current path 23 , a first combined circuit 21 , a second combined circuit 22 and a voltage limiter 15 . The initial current path includes a power electronics module 13 and a mechanical switch module 12; the first combined loop includes an inductor 11 and a capacitor 16, and the second combined loop includes an inductor 14, a capacitor 17, and a capacitor The charging circuit has a built-in switch 5, 0 and a capacitor charging circuit resistor 49.

[0048] The initial current path includes a power electronics module 13 and a mechanical switch module 12; the first combined loop includes an inductor 11, a capacitor 16 and a built-in mechanical switch 61, and the second combined loop includes an inducto...

Embodiment 2

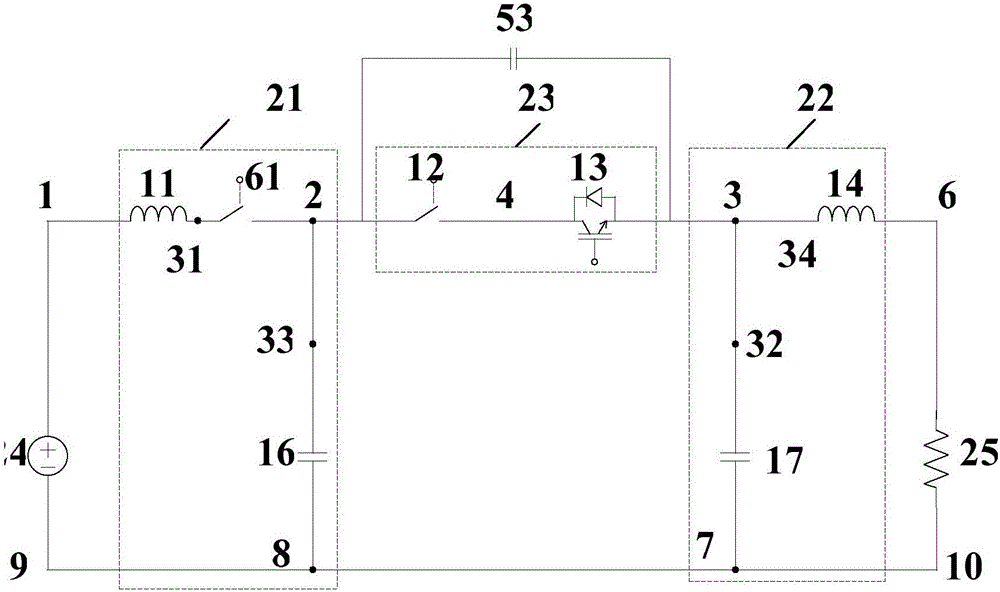

[0052] image 3 Shown is Example 2 of the present invention. image 3 The two ends of the capacitor 53 are connected to the two ends of the initial current loop 23 respectively.

Embodiment 3

[0054] Figure 4 Shown is embodiment 3 of the present invention, between the first combined loop second lead-out terminal 2 and one end 33 of the first combined loop capacitor, add a capacitor pre-charging circuit 41, and the pre-charging circuit 41 is composed of a pre-charging resistor 44, a pre-charging switch 45 and a precharge bypass switch 46, one end of the precharge resistor 44 is connected to one end of the precharge switch 45, and the other end of the precharge resistor 44 is used as the first lead-out terminal of the precharge circuit 41 to connect with the precharge bypass switch 46 One end is connected, and the other end of the pre-charging switch 45 is connected to the other end of the pre-charging bypass switch 46 as the second lead-out terminal of the pre-charging circuit 41 . When the system is just started, the pre-charge switch 45 is closed, and the pre-charge bypass switch 46 is disconnected to pre-charge the short-circuit oscillating current path capacitor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com