A high voltage direct current circuit breaker

A DC circuit breaker, high-voltage DC technology, applied in circuit devices, emergency protection circuit devices for limiting overcurrent/overvoltage, emergency protection circuit devices, etc., can solve the high cost of DC circuit breakers, the impact of breaking speed, The current can not be turned off and other problems, to achieve the effects of rapid topology breaking, high reliability, and low manufacturing difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

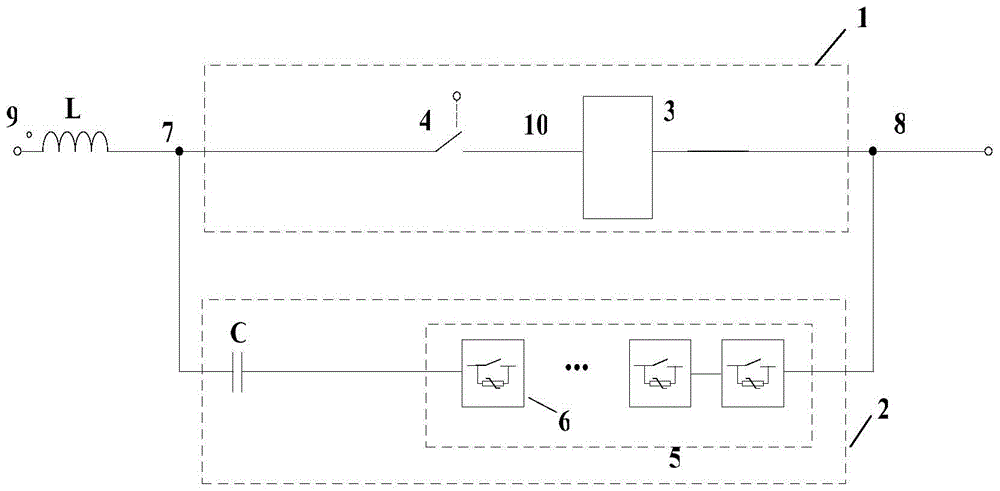

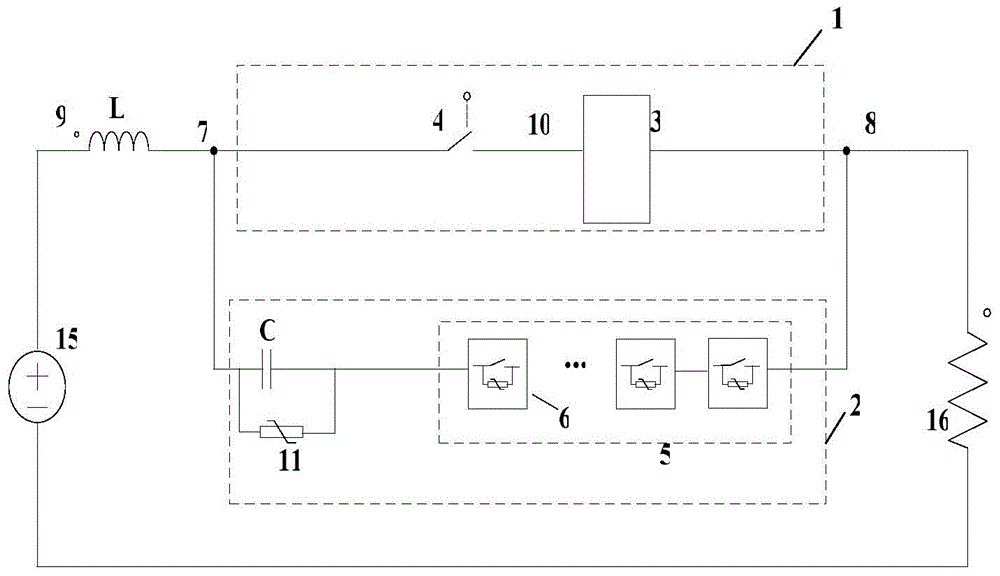

[0056] figure 2 Shown is Example 1 of the present invention. Such as figure 2 As shown, the DC power supply 15 is an analog converter station, and the inductance L is a current-limiting reactor built in the analog converter station. One end of the inductance is connected to the positive pole 9 of the converter station, and the other end of the inductance is connected to the first outlet of the DC circuit breaker. Terminal 7 connection. Resistor 16 is a short-circuit simulation resistor. The basic structure of the DC circuit breaker topology of the present invention is composed of an initial current path 1 and a fault current blocking path 2 . The first lead-out terminal of the initial current path 1 is connected to the first lead-out terminal of the fault current blocking path 2 as the first lead-out terminal 7 of the DC circuit breaker is connected to the external line, and the second lead-out terminal of the initial current path 1 is connected to the fault current resis...

Embodiment 2

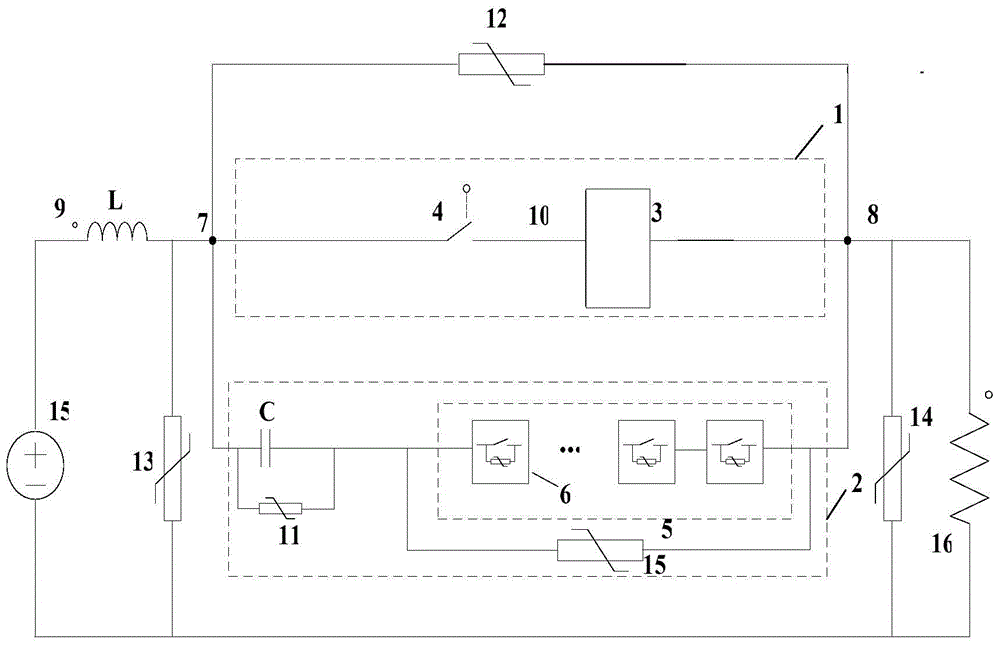

[0062] image 3 Shown is Example 2 of the present invention. Such as image 3 As shown, two series-connected voltage limiters 13 and 14 are connected in parallel at both ends of the initial current path 1, a voltage limiter 12 is connected in parallel at both ends of the capacitor module C of the fault current blocking path 2, and the series part of the modular switching subunit 5 A voltage limiter 15 is connected in parallel at both ends. Between the first lead-out terminal of the initial current path 1 and the ground, and between the second lead-out terminal of the initial current path 1 and the ground, for overvoltage protection of various parts of the entire DC circuit breaker. It is also possible to selectively add voltage limiting devices at both ends of the place where protection is required.

Embodiment 3

[0064] Figure 4 Shown is Example 3 of the present invention. Figure 4 The medium voltage source 15 is the converter station, the resistor 16 is the short-circuit analog terminal, the inductance L is the current-limiting reactor of the analog converter station, one end of the inductance is connected to the positive pole 9 of the converter station, and the other end of the inductance is connected to the DC circuit breaker The first lead-out terminal 7 is connected. The fault current blocking path 2 in this embodiment is composed of a capacitor module C and a series part 5 of modular switching subunits.

[0065] Figure 4 The power electronic switch module 3 in the initial current path 1 adopts a semi-controlled device thyristor. The power electronic switch module 3 can also be composed of multiple thyristors connected in series. In this way, the conduction loss of the entire DC circuit breaker is lower when the DC grid is operating normally, but since the thyristor has no ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com