Welding helix structure of traveling-wave tube

A technology of helix and traveling wave tube, applied in the field of microwave devices

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

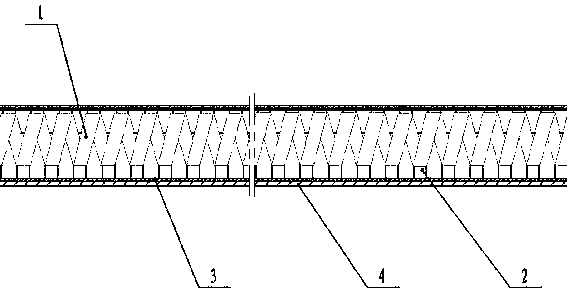

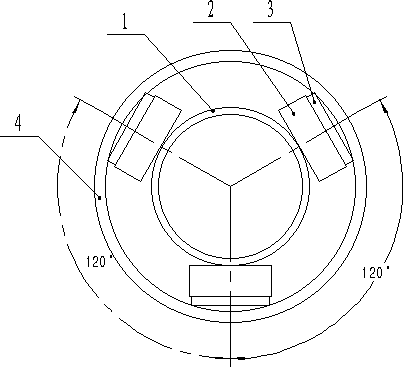

[0010] Although the helical welding structure of the existing traveling wave tube can improve the heat dissipation capacity of the traveling wave tube, it affects the electronic efficiency of the traveling wave tube. In order to solve the above problems, the present invention provides a welding helical structure of the traveling wave tube, which adopt Compared with the existing traveling wave tube with welded helix structure, the traveling wave tube with welded helix structure of the present invention reduces the load, increases the coupling impedance, improves the electronic efficiency, and significantly improves the speed of the helix. The reliability of the wave improves the overall tube efficiency of the traveling wave tube; the total heat consumption of the traveling wave tube is reduced, and the working stability and reliability of the traveling wave tube are improved.

[0011] Below in conjunction with the accompanying drawings of the present invention, the technical sol...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap