Lithium ion battery silicon negative electrode sheet and preparation method thereof, and lithium ion battery

A lithium-ion battery, silicon anode technology, applied in electrode manufacturing, battery electrodes, secondary batteries, etc., can solve the problem of shortening the cycle life of lithium-ion batteries, high energy consumption for the production of porous silicon anodes, and increasing the volume of lithium-ion batteries. It can solve the problems such as large and other problems, and achieve the effect of simple and easy preparation method, easy industrial production and good connectivity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

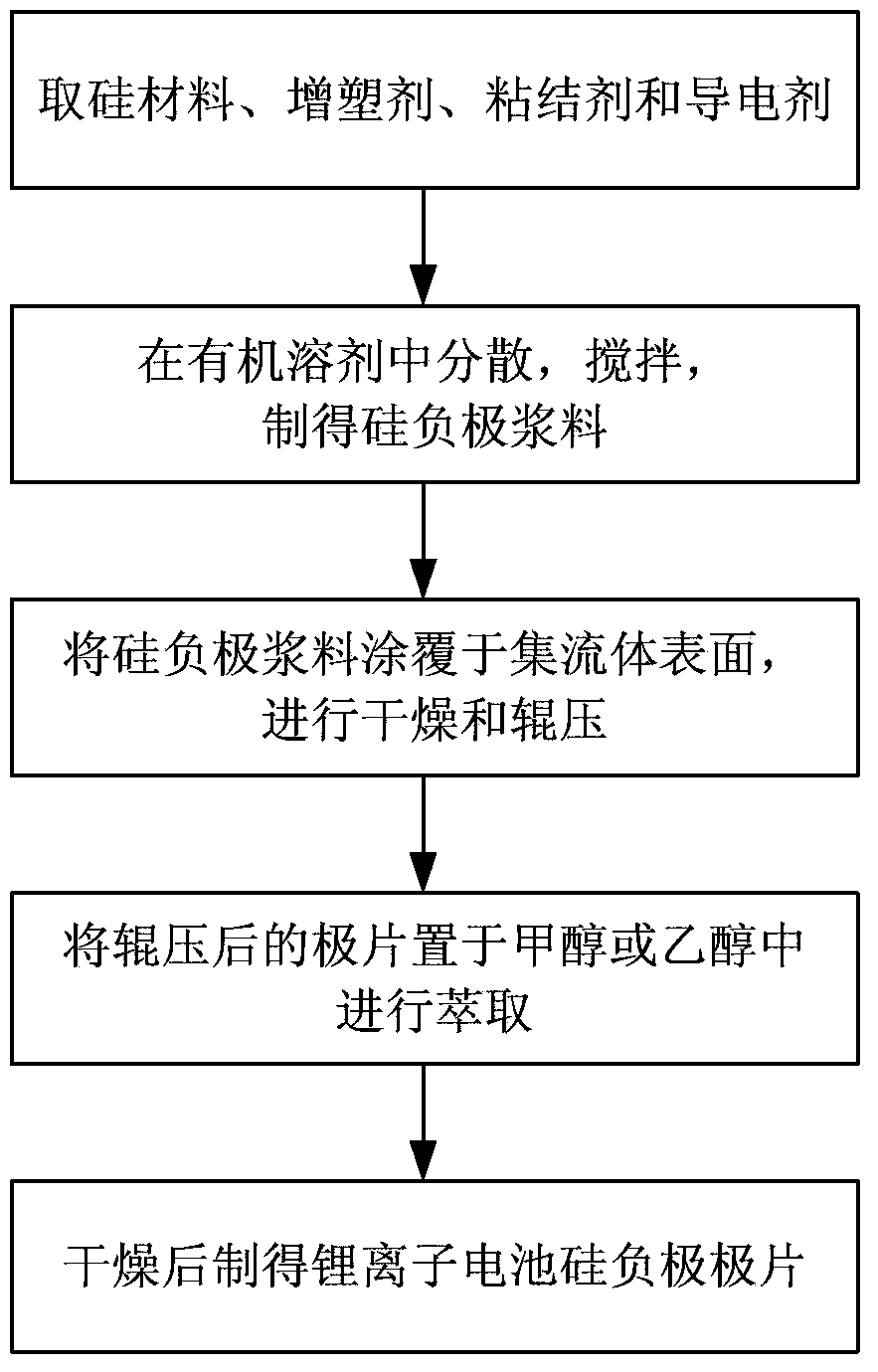

[0035] In the first aspect, the embodiment of the present invention provides a method for preparing a silicon negative electrode sheet of a lithium ion battery, such as figure 1 shown, including the following steps:

[0036] (1) Get the silicon material, plasticizer, binding agent and conductive agent to form the solid batching component of the silicon negative electrode slurry, disperse the solid batching component in an organic solvent, stir, and make the silicon negative electrode slurry, and The plasticizer accounts for 4% to 30% of the total weight of the silicon negative electrode slurry solid ingredients;

[0037] (2) Coating the silicon negative electrode slurry on the surface of the current collector, drying and rolling, then placing the rolled pole piece in methanol or ethanol for extraction, and drying to obtain a silicon negative electrode for lithium ion batteries piece.

[0038] In the first aspect of the embodiment of the present invention, a silicon negative ...

Embodiment 1

[0066] A method for preparing a silicon negative electrode sheet of a lithium ion battery, comprising the following steps:

[0067] (1) Get silicon nanoparticle, dibutyl phthalate, polyvinylidene fluoride and acetylene black to form silicon negative electrode slurry solid batching component respectively, with 30 grams of polyvinylidene fluoride, join 1400 grams of N-2- In the methylpyrrolidone solution, stir for 4 hours, then add 180 grams of dibutyl phthalate, stir for 4 hours, then add 30 grams of acetylene black, stir for 2 hours, finally add 360 grams of silicon nanoparticles, stir for 6 hours, the stirring temperature Both are at 35°C to obtain a stable silicon negative electrode slurry;

[0068] (2) Coating the silicon negative electrode slurry on the surface of the plane copper foil, the coating weight is 5.82g / cm 2 (without copper foil), dried in an oven at 80°C, and then rolled to a thickness of 0.077mm, cut into strip-shaped pole pieces with a width of 40mm, and the...

Embodiment 2

[0076] A method for preparing a silicon negative electrode sheet of a lithium ion battery, comprising the following steps:

[0077] (1) Get silicon oxygen carbon composite material, propylene glycol adipate polyester, epoxy resin and graphite to form silicon negative electrode slurry solid batching component respectively, with 20 grams of epoxy resins, join 500 grams of N, N-dimethyl In the base formamide solution, stirred for 4 hours, then added 40 grams of propylene glycol adipate, stirred for 4 hours, then added 15 grams of graphite, stirred for 2 hours, and finally added 425 grams of silicon-oxygen-carbon composite materials, stirred for 6 hours, and the stirring temperature Both are at 40°C to obtain a stable silicon negative electrode slurry;

[0078] (2) Coating the silicon negative electrode slurry on the surface of the plane copper foil, the coating weight is 5.82g / cm 2 (without copper foil), dried in an oven at 100°C, and then rolled to a thickness of 0.077mm, cut i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Aperture size | aaaaa | aaaaa |

| Aperture | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap