Electrolysis cell and cathode with irregular surface profiling

An electrolytic cell and cathode technology, applied in the field of electrolytic cells, can solve the problems that the service life cannot be extended, reduce the specific energy consumption of the electrolytic cell, and achieve the effect of less fluctuations forming potential distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

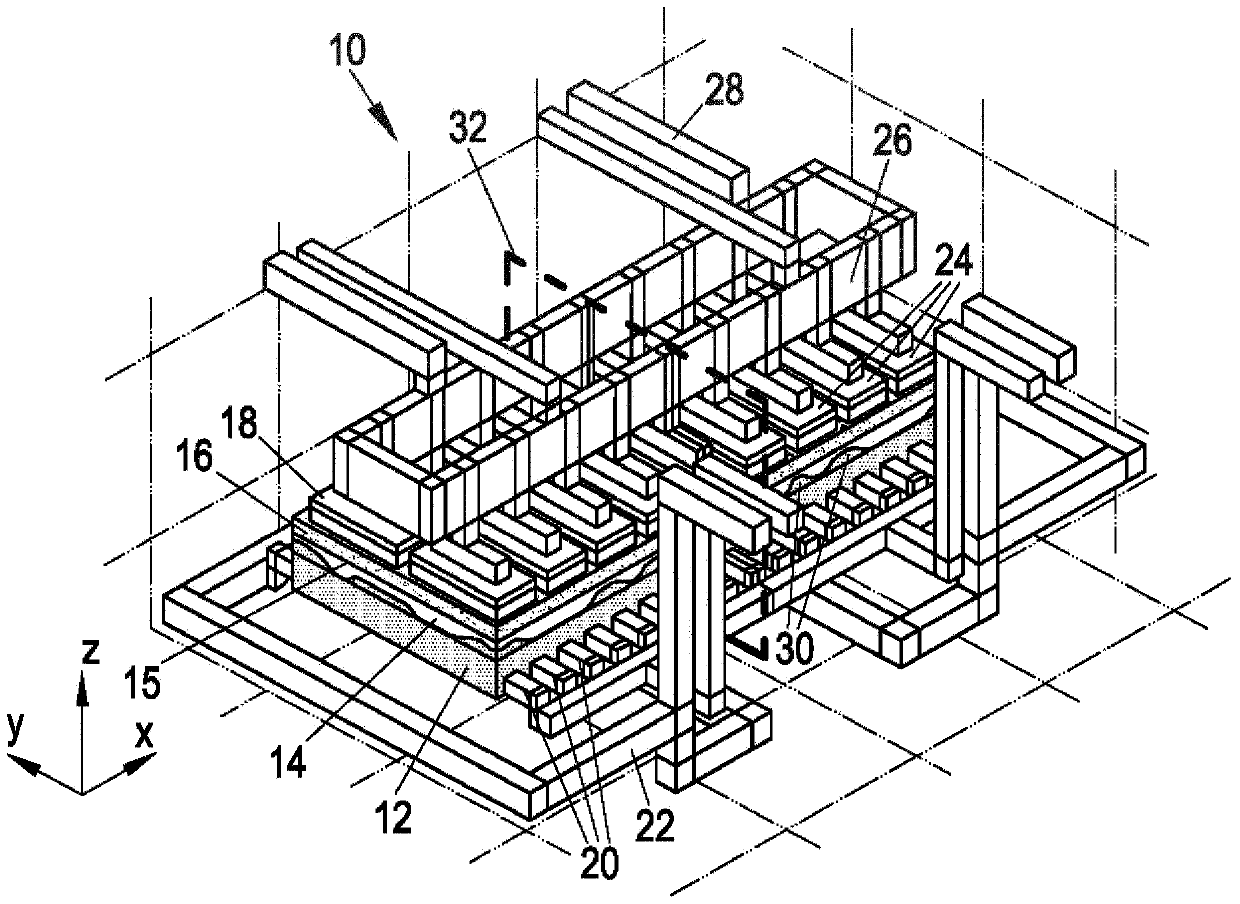

[0185] figure 1 Shown is an electrolytic cell 10 for aluminum production, said electrolytic cell comprising a cathode 12, a layer 14 of liquid aluminum on top of said cathode 12, a layer 16 of melt on top of said layer of liquid aluminum, and an anode 18 located above the melt layer 16 . The liquid aluminum layer 14 and the melt layer merge into each other at the boundary surface 15 .

[0186] The cathode 12 is composed of a plurality of elongated cathode blocks, which extend along the horizontal direction y of the electrolytic cell 10, are arranged side by side along the longitudinal direction x of the electrolytic cell 10, and are connected to each other by a tamping connector not shown in the figure . Inserted into the underside of each cathode block is a busbar 20 which passes through the cathode block in its longitudinal direction y and makes electrical contact with the cathode block.

[0187] The busbars 20 are brought together by current leads 22 , which are geometri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com