Corn husker

A technology of peeling machine and corn, applied in agricultural machinery and implements, threshing equipment, application and other directions, can solve problems such as poor adaptability of corn peeling machine, and achieve the effects of improving peeling efficiency, improving processing capacity and preventing peeling.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

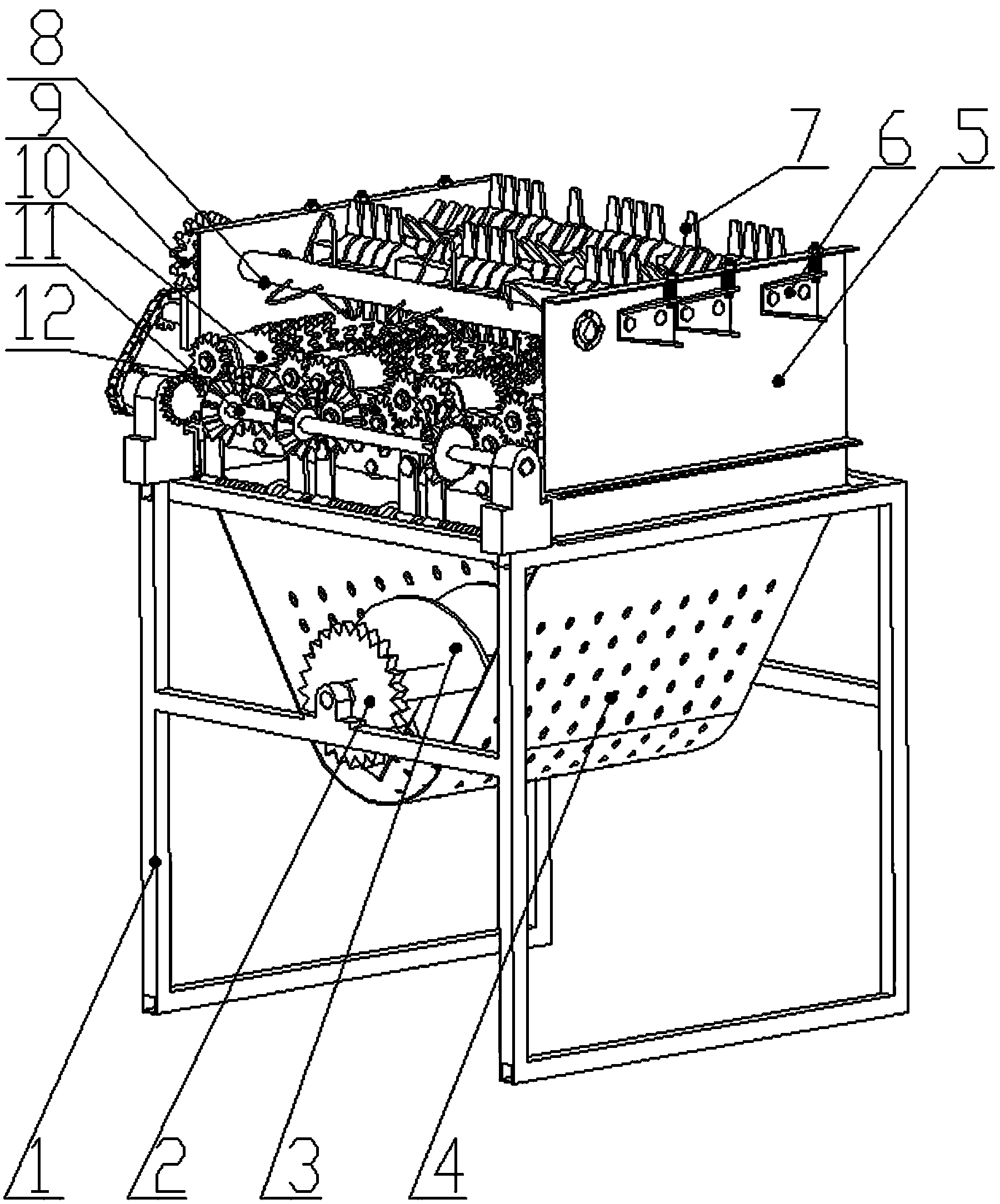

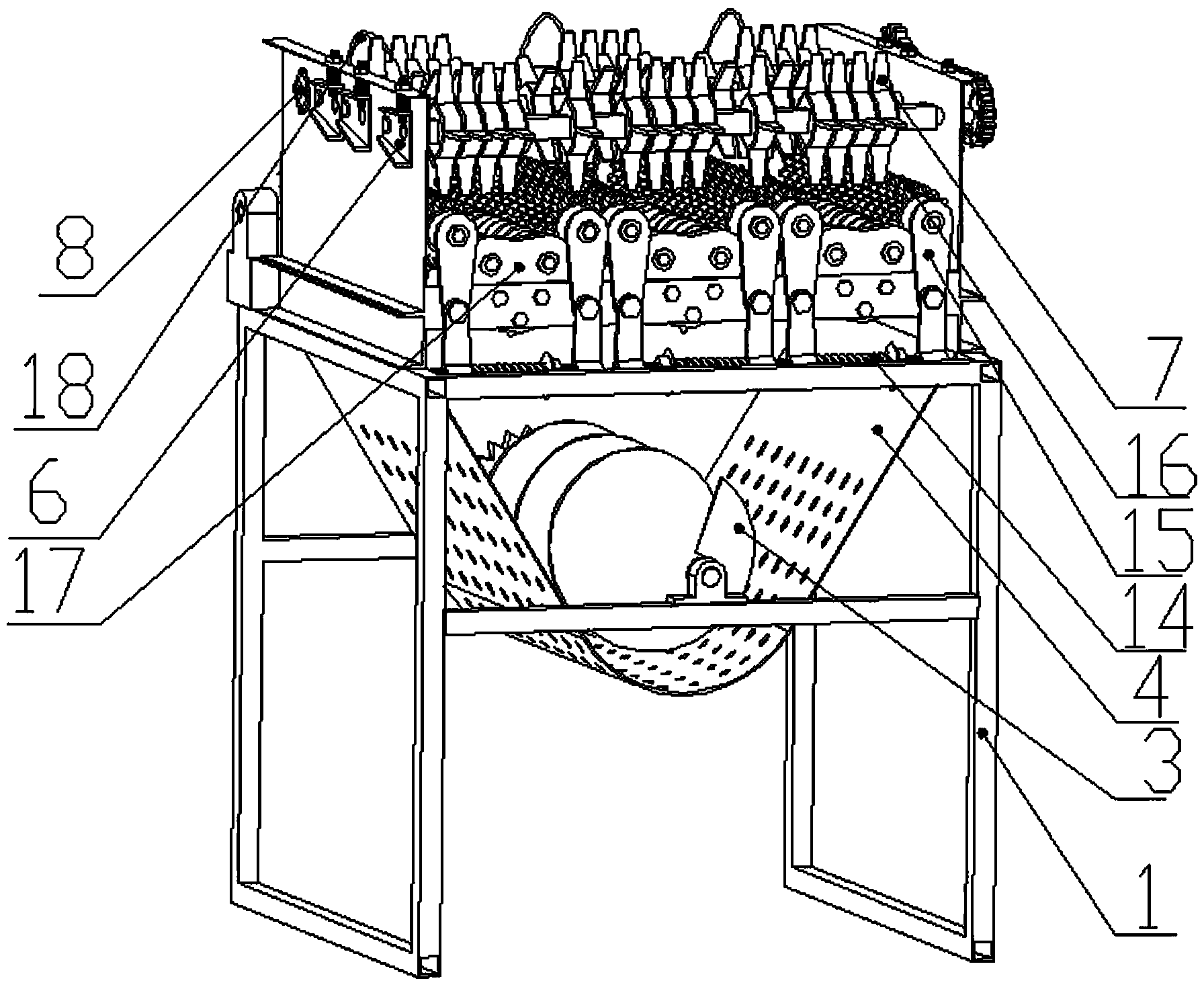

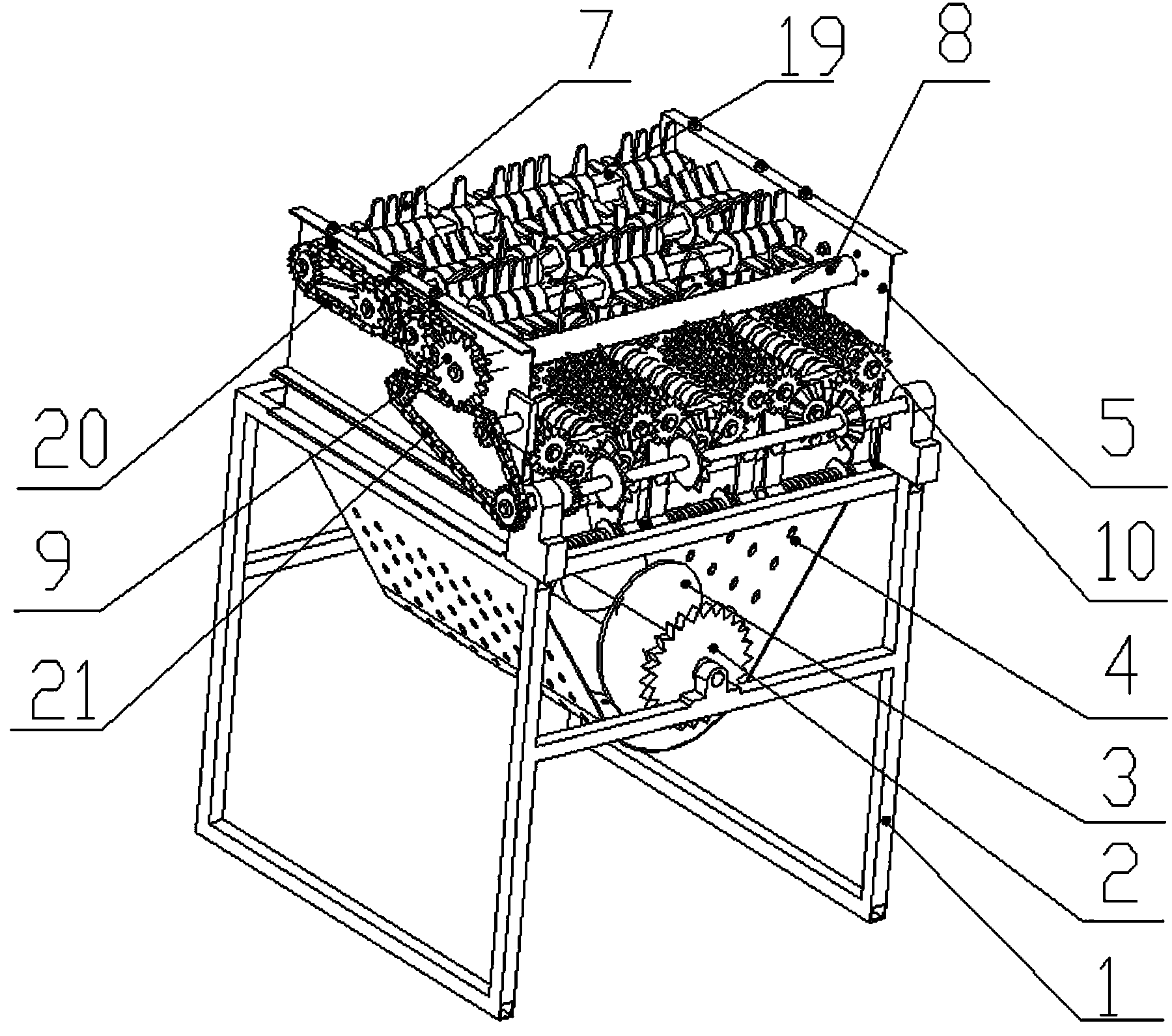

[0025] A corn peeling machine as shown in the figure includes a peeling mechanism, a transmission mechanism, an ear skin removal mechanism, a frame, a distribution mechanism and a pressure conveying mechanism, and the upper part of the frame 1 is provided with a distribution mechanism and a pressure conveying mechanism, The middle part of the frame 1 is provided with a peeling mechanism and a transmission mechanism, and the lower part of the frame 1 is provided with an ear peel removal mechanism, and the transmission mechanism is respectively connected with the apportionment mechanism, the pressure conveying mechanism, the peeling mechanism and the ear peel removal mechanism; The rotating shaft 8 and the distributing teeth 18, the pressure conveying mechanism includes a rotating shaft 22 and a quincunx wheel 7, and the material of the quincunx wheel 7 is rubber.

[0026] The peeling mechanism includes a fish scale roller group and a spiral conveying roller group, the fish s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com