A drum type magnetic separator with roughing and sweeping functions

A drum-type, magnetic separator technology, applied in the fields of magnetic separation, solid separation, chemical instruments and methods, etc., can solve the problems of low processing capacity of magnetic separator, affecting the processing capacity of a single unit, large load on the drum spindle, etc. Control the grade of tailings, improve the processing capacity of a single unit, and meet the effects of large-scale production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

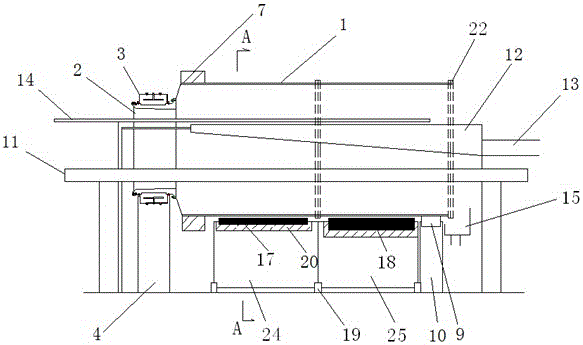

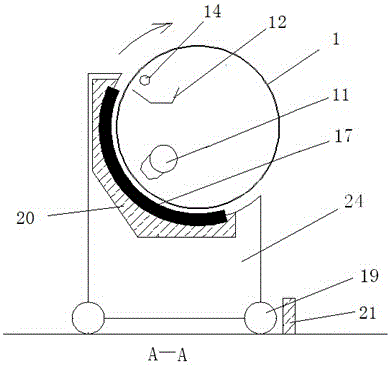

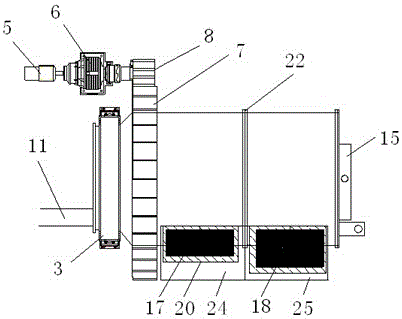

[0019] The present invention includes a drum 1, a rotating shaft 2, a rotating bearing 3, a bearing housing 4, a motor 5, a reducer 6, a large ring gear 7, a pinion 8, an idler 9, an idler bracket 10, an ore feeding pipe 11, and a concentrate Bucket 12, unloading water pipe 14, tailings collection tank 15, rough separation magnetic system 17, sweep magnetic system 18, rough separation magnetic system trolley 24 and sweep separation magnetic system trolley 25.

[0020] figure 1 , 2 , 3 show that the structure of the present invention is very different from the structure of the existing drum-type magnetic separator, the magnetic system is located on the outside of the drum 1, and the ore feeding pipe 11, the unloading water pipe 14 and the concentrate bucket 12 Place in drum 1. The magnetic system includes a rough selection magnetic system 17 and a sweep magnetic system 18, which are independent of each other. The rough selection magnetic system 17 and the sweep magnetic syste...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com