Anti-bursting batch processing shell breaking device

A batch processing and shell breaker technology, applied in the field of food processing, can solve the problems of low processing efficiency and complicated operation, and achieve the effect of improving processing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

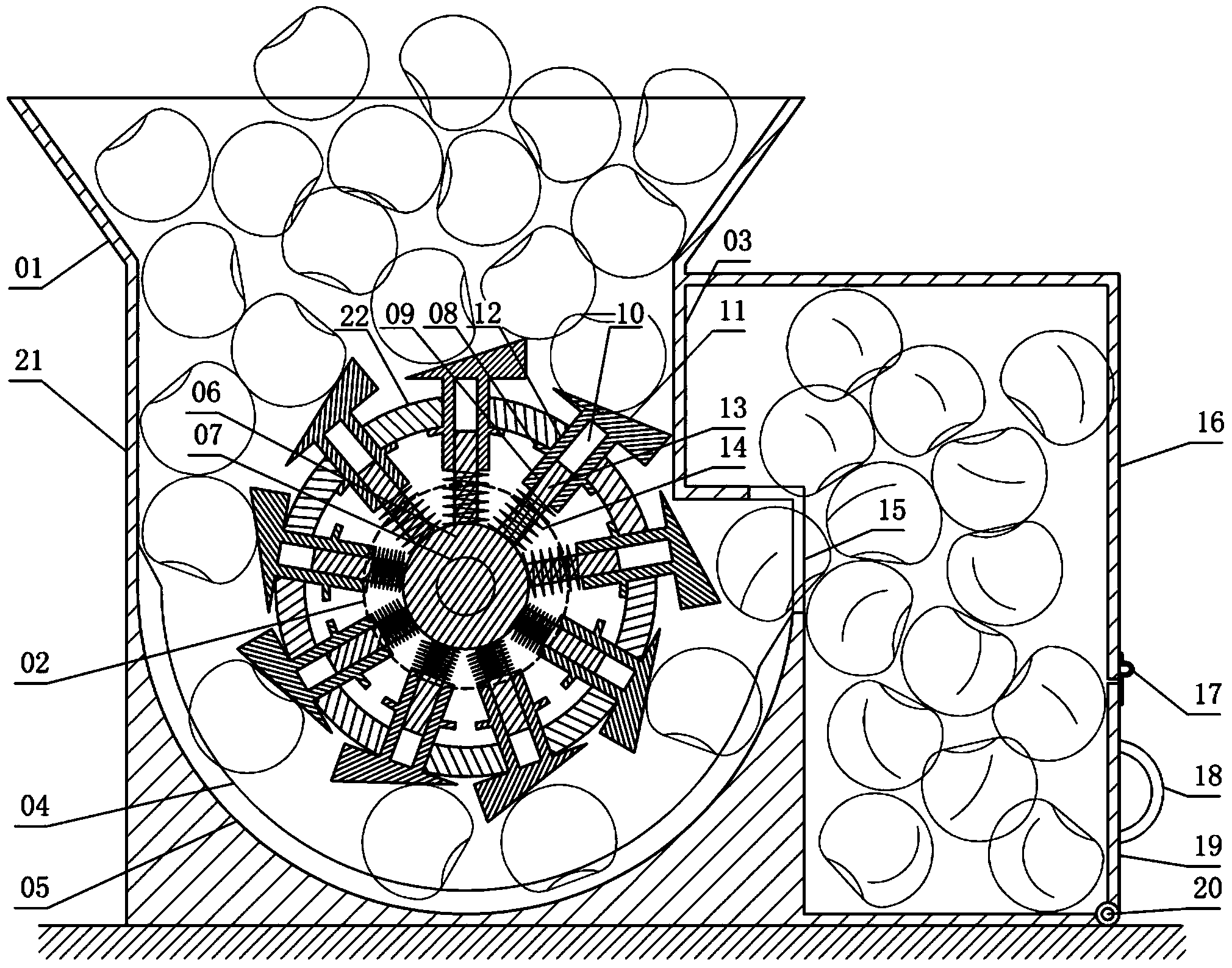

[0017] Anti-crack batch processing shell breaker, consisting of hopper 01, motor 02, isolation plate 03, blade 04, slot 05, turntable 06, rotating shaft 07, limit piece 08, sleeve rod 09, rod hole 10, propulsion block 11, wheel Hole 12, main bar 13, spring 14, pass fruit door 15, storage box 16, snap close 17, handle 18, go out fruit door 19, hinge 20, operation box 21 and wheel box 22 constitute.

[0018] Wherein, the operation box 21 and the storage box 16 are arranged side by side, separated by the isolation plate 03 between the two, and a fruit-passing door 15 is opened on the isolation plate 03, and the upper end of the operation box 21 is integrated with the operation box 21 The hopper 01 has an arc-shaped slot 05 at the bottom of the operation box 21, and the arc-shaped blade 04 is inserted in the slot 05 with the blade 04 facing upward. The out...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com