Tobacco humectant

A humectant and tobacco technology, which is applied in the fields of tobacco, tobacco processing, sugar derivative preparation, etc., can solve the problems of maintaining the moisture content of finished cigarettes, and the improvement effect of sensory comfort is not ideal, so as to enhance the sensory preservation of cigarettes. The effect of moisturizing function, abundant and cheap raw materials, and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

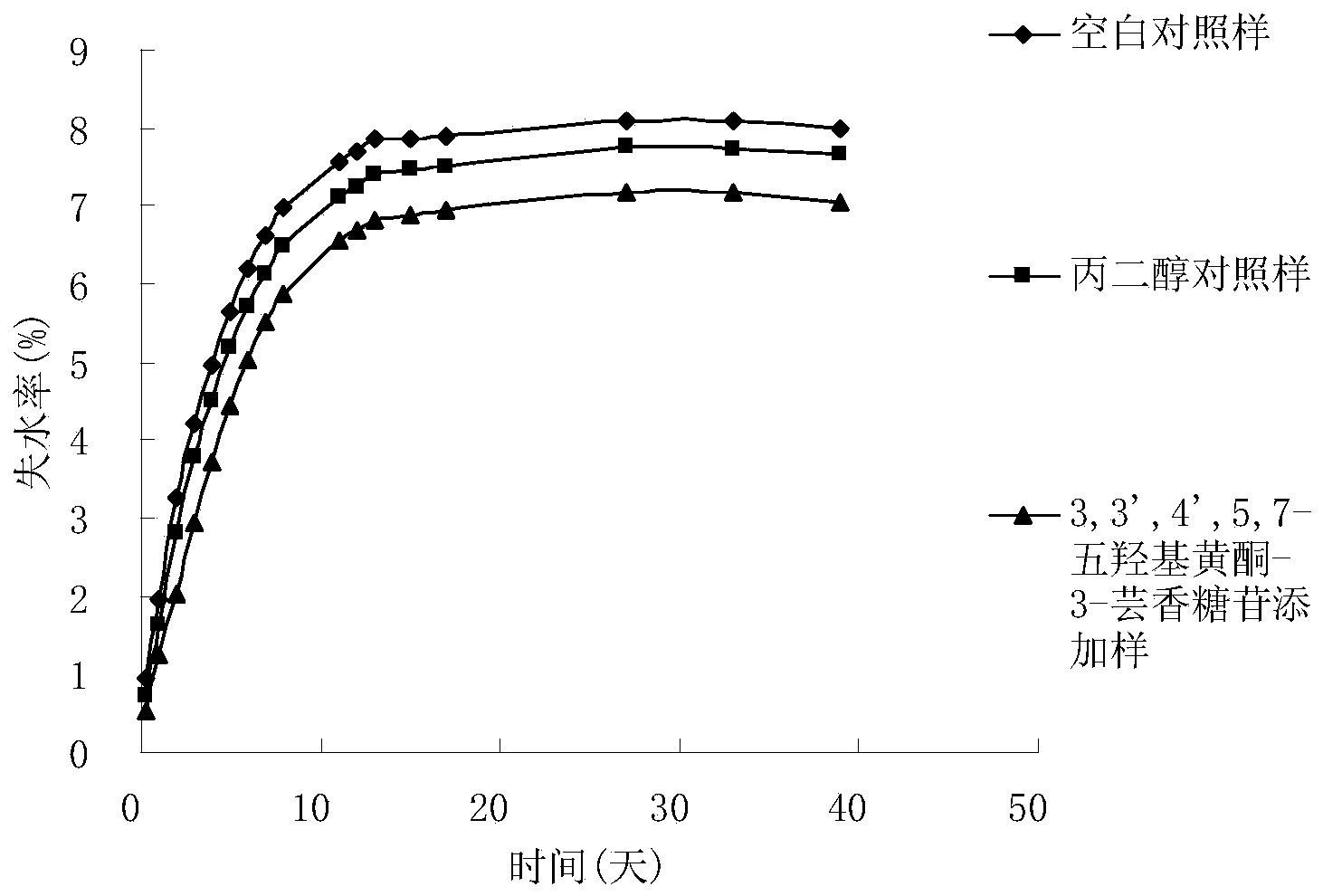

[0024] The 3,3',4',5,7-pentahydroxyflavone-3-rutinoside compound solution prepared in the preparation example was added to the shredded tobacco according to the amount of humectant at 0.2%, so that the shredded tobacco without adding the sample and adding the same amount of propylene glycol The samples were used as blank and control, respectively. Then the processed cut tobacco samples were placed in a constant temperature and humidity chamber with a temperature of 21°C and a relative humidity of RH45%, weighed once at regular intervals, and were continuously weighed several times to calculate the water loss rate of the cut tobacco respectively. Take time as the abscissa, and the sample dehydration rate as the ordinate, draw the dehydration curve of the sample over time, such as figure 1 shown.

[0025] The results show that 3,3',4',5,7-pentahydroxyflavone-3-rutinoside has a reducing effect on the water loss of shredded tobacco in a dry environment, and its effect is better t...

Embodiment 2

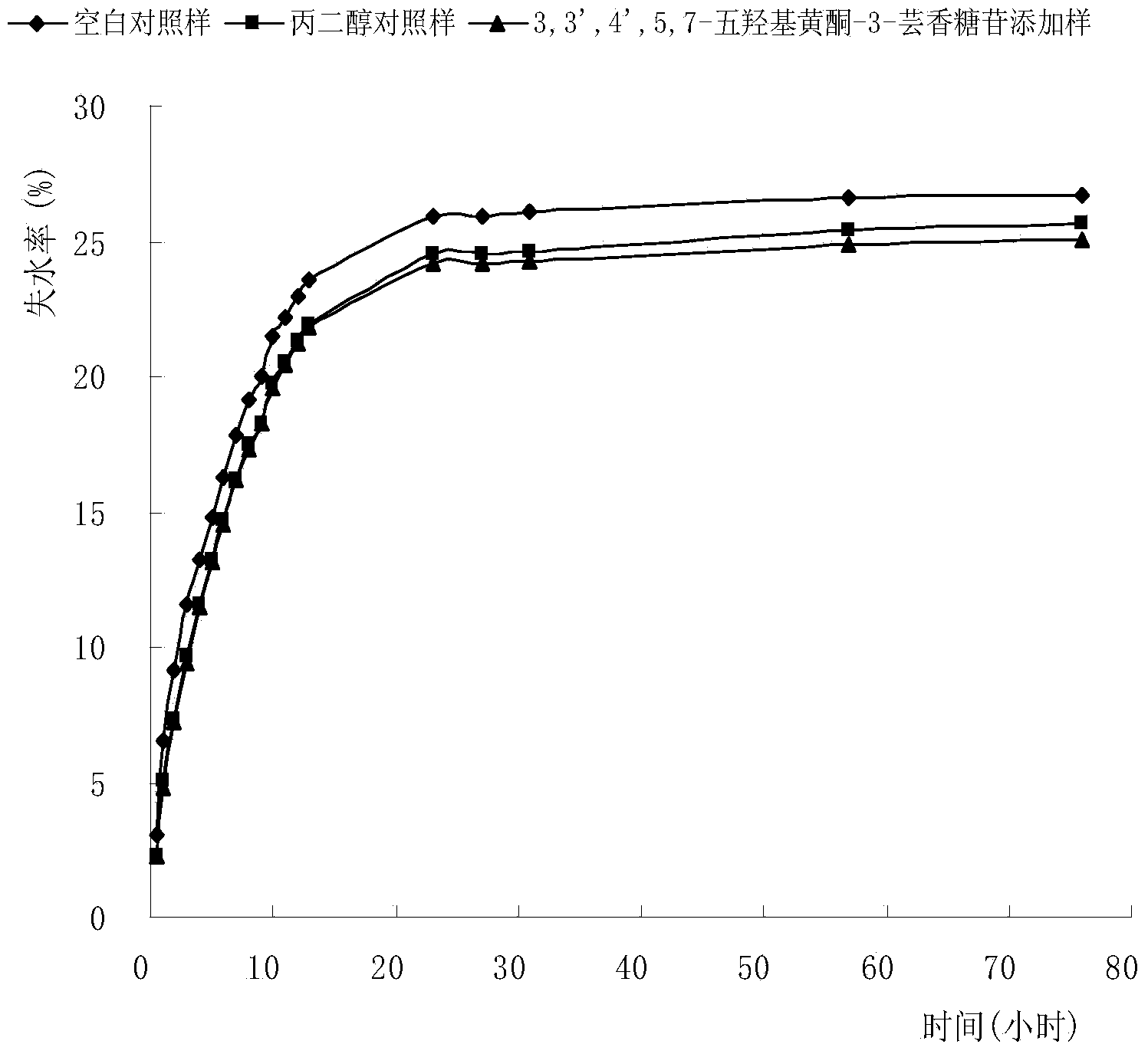

[0027] The 3,3',4',5,7-pentahydroxyflavone-3-rutinoside compound solution prepared in the preparation example was added to the shredded tobacco according to the amount of humectant of 0.3%, so that the shredded tobacco without adding the sample and adding the same amount of propylene glycol The samples were used as blank and control respectively; then the treated shredded tobacco samples were placed in a constant temperature and humidity chamber with a temperature of 28°C and a relative humidity of RH22%. water rate. Take time as the abscissa, and the sample dehydration rate as the ordinate, draw the dehydration curve of the sample over time, such as figure 2 shown.

[0028] The test results show that 3,3',4',5,7-pentahydroxyflavone-3-rutinoside has a reducing effect on the water loss of shredded tobacco in a high-temperature and extremely dry environment, and its effect is better than that of the propylene glycol control group and the blank control group. It helps to maint...

Embodiment 3

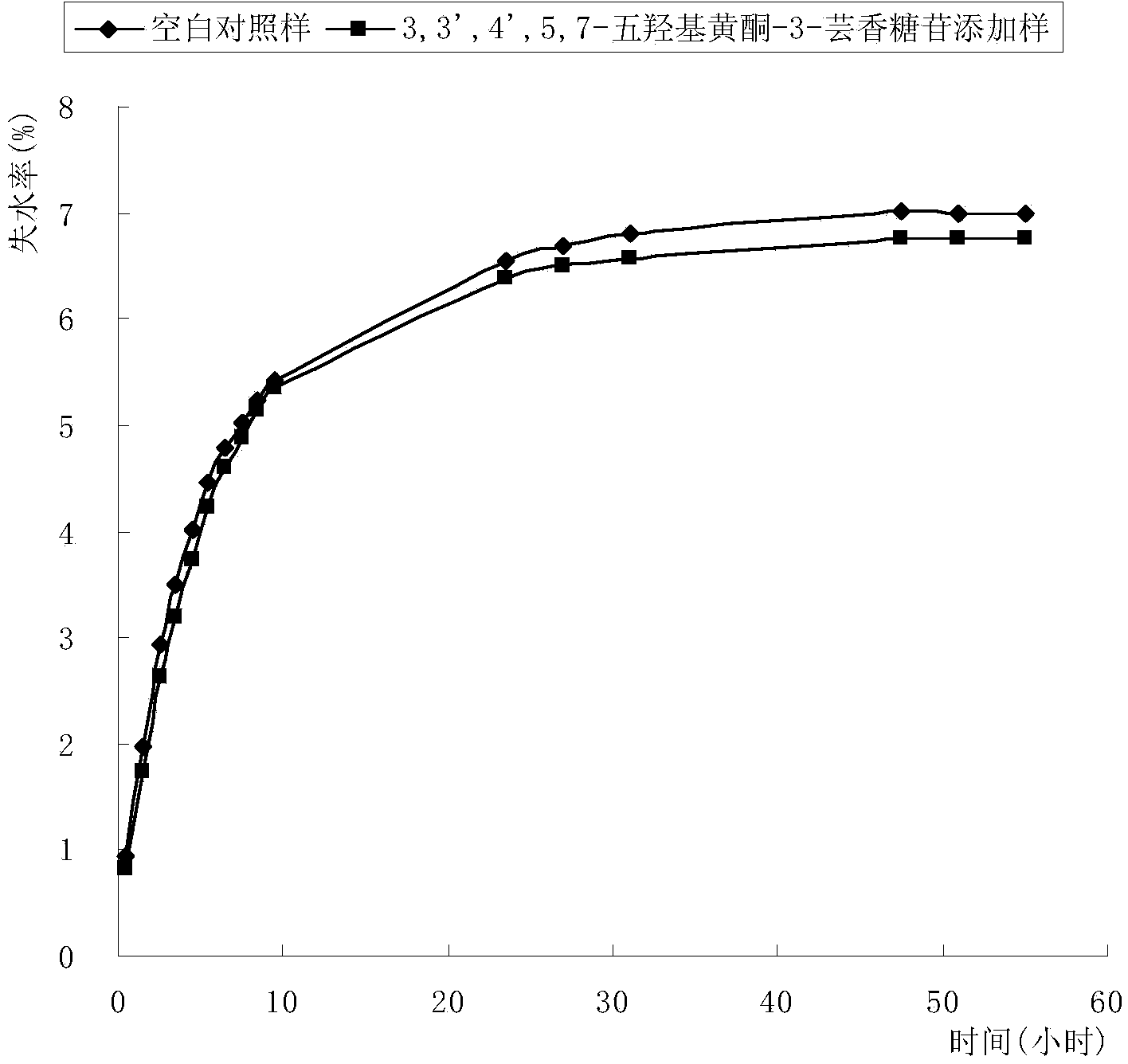

[0030] The 3,3',4',5,7-pentahydroxyflavone-3-rutinoside compound solution prepared in the preparation example was added to the shredded tobacco of brand A cigarette according to the amount of humectant 0.16%, so as to add an equal amount of propylene glycol to the shredded tobacco The sample is the control, and the blank sample is an equal volume of absolute ethanol added to the shredded tobacco of brand A cigarettes. Then the processed cut tobacco samples were placed in a constant temperature and humidity chamber with a temperature of 22°C and a relative humidity of RH30%, and the samples were continuously weighed several times at intervals of a certain period of time, and the water loss rate of the cut tobacco was calculated respectively. Take time as the abscissa, and the sample dehydration rate as the ordinate, draw the dehydration curve of the sample over time, such as image 3 shown. The sensory quality evaluation of cigarette samples was carried out, and the results sh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com