A diode bending die

A diode and bending technology, which is applied in the field of diode bending molds, can solve problems such as time-consuming, labor-intensive, and difficult problems, and achieve the effects of reducing danger, reducing work difficulty, and ensuring stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

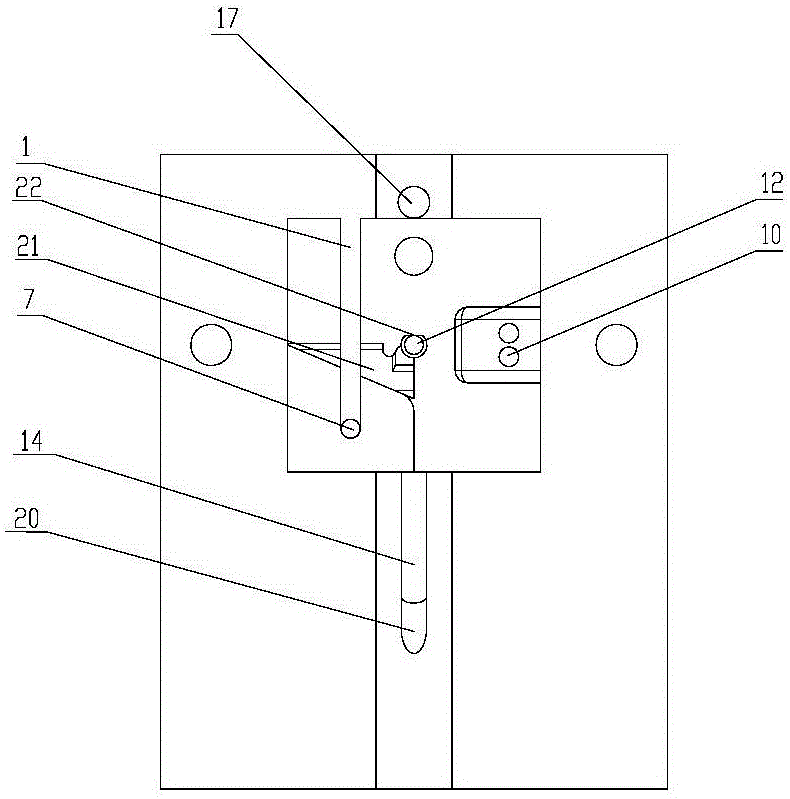

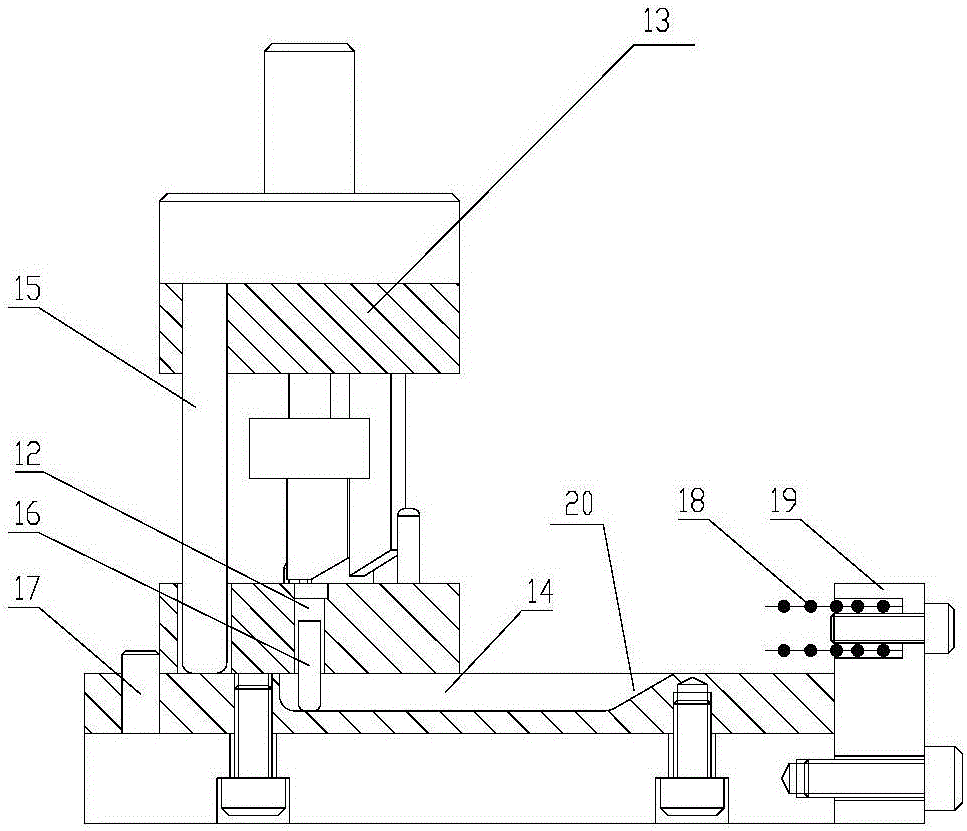

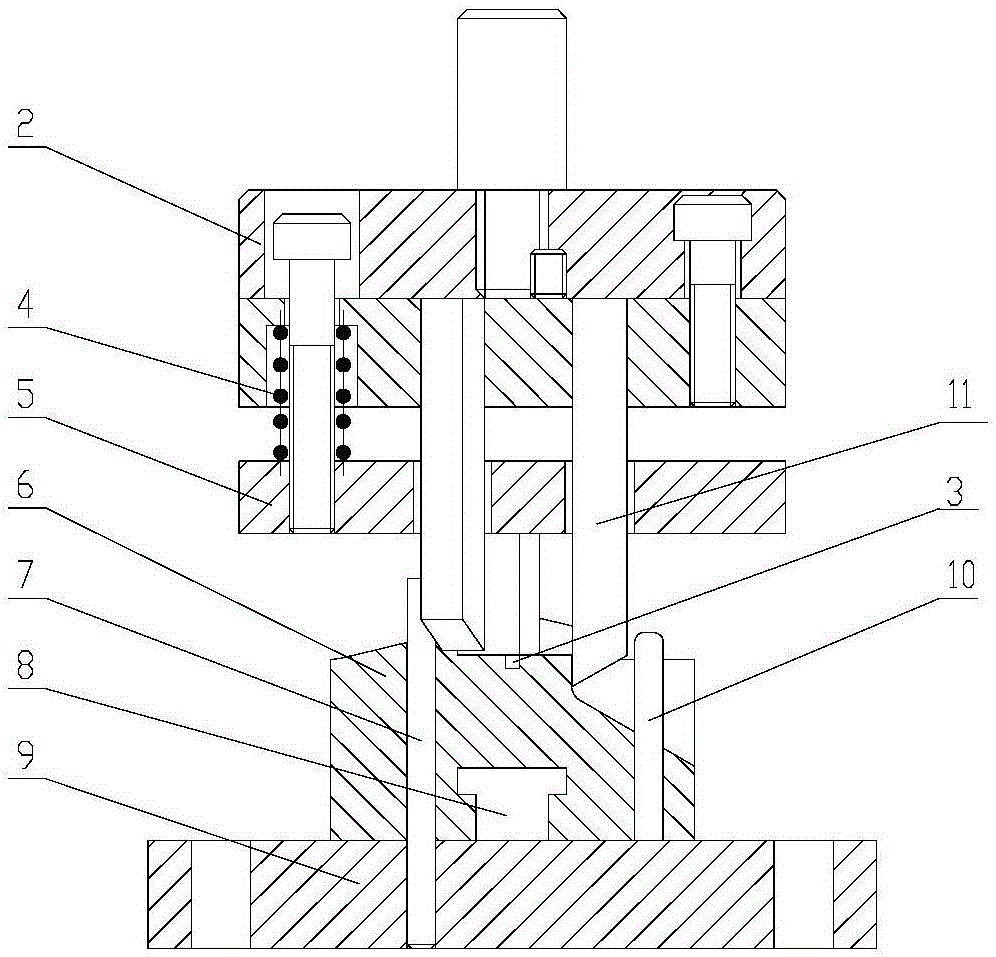

[0019] A diode bending mold, comprising a lower mold 6 and a bottom plate 9; a slide rail 8 and a guide post 7 are installed on the bottom plate 9, and the guide post 7 is fixedly arranged on one side of the slide rail 8; The other side of 8 is also provided with a limit column 10, and the lower mold 6 is slidingly matched with the slide rail 8; A positioning hole 12 for positioning the diode is arranged between the track groove 1 and the track groove 1 . The limiting posts 10 are two upright posts with a distance equal to the thickness of the anode or cathode of a diode.

[0020] After the diode is bent, it is convenient to pick up the parts. The slide rail 8 is provided with a U-shaped groove 14 that matches the positioning hole 12, and a movable push pin 16 is arranged in the positioning hole 12. One section is in the U-shaped groove 14 ; one end of the U-shaped groove 14 is provided with an axial slope 20 of the U-shaped groove.

[0021] Further, after the lower mold sli...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com