High-precision drilling clamp

A drilling jig and high-precision technology, which is applied in the field of tooling fixtures, can solve problems such as high machining accuracy requirements, and achieve the effects of high clamping efficiency, simple structure, and high machining accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0009] The specific implementation manner of the present invention will be described below in conjunction with the accompanying drawings.

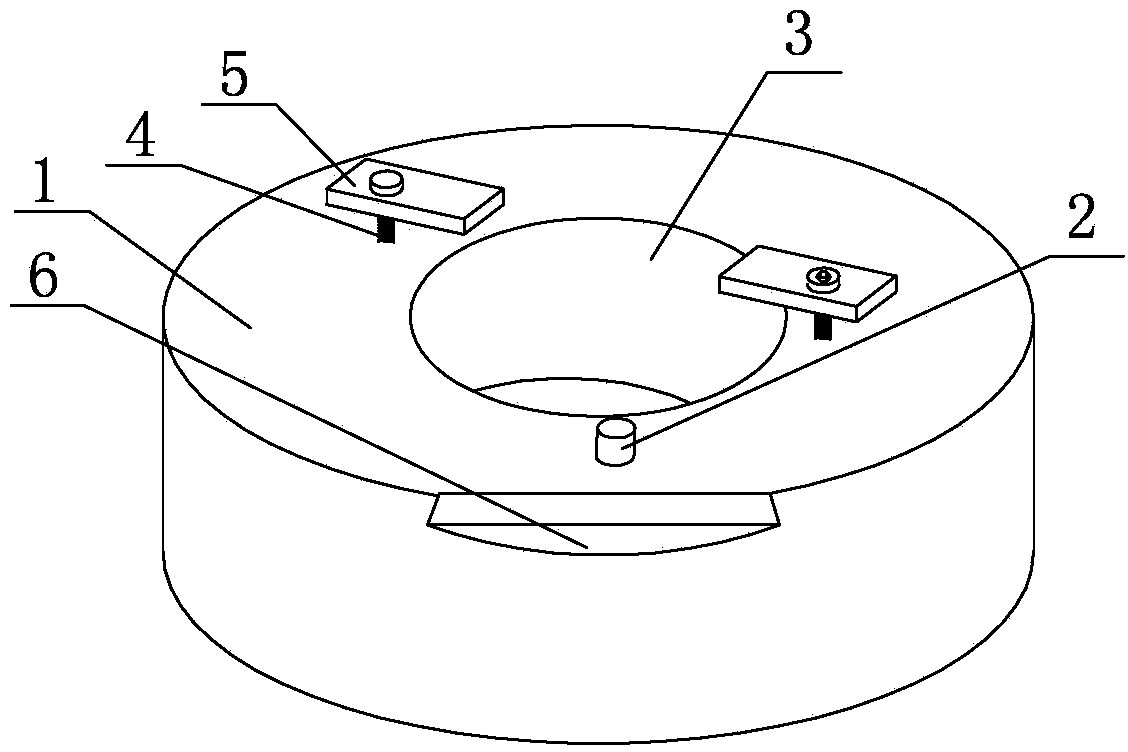

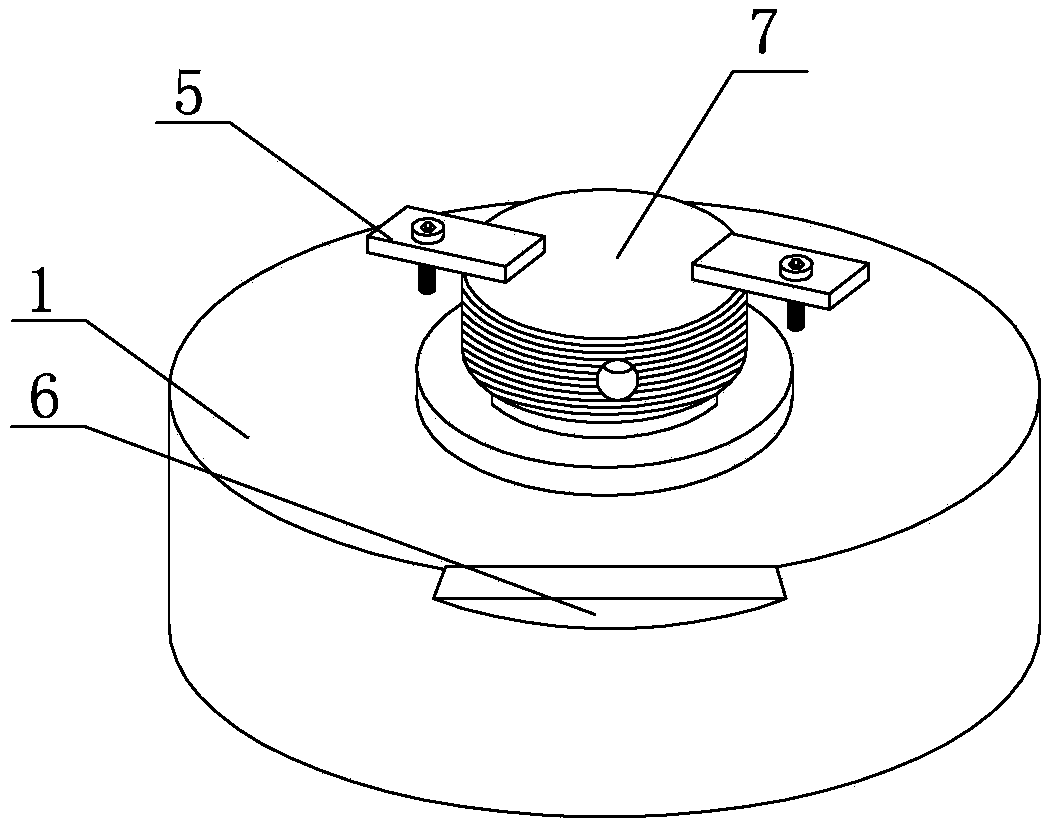

[0010] Such as figure 1 and figure 2 As shown, the present invention includes a positioning disc 1, which has a positioning pin 2, a central positioning hole 3 and a pair of bolts 4 on the positioning disc 1, and the positioning pin 2 cooperates with the positioning hole on the chassis of the workpiece 7 to limit the rotation of the workpiece 7. The central positioning hole 3 is matched with the cylindrical section on the workpiece 7. A pair of bolts 4 are symmetrical about the axis of the positioning hole 3. The bolts 4 are equipped with a pressure block 5, which acts on the end surface of the workpiece 7, which can ensure that the force is relatively stable. Evenly balanced, the end face of the positioning plate 1 has a step 6, after positioning the workpiece 7, check whether the plane of the step 6 is horizontal, and can judge whether...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com