Fluid plastic thin-wall elastic sleeve clamp with magnetic isolation performance

A liquid plastic, elastic sleeve technology, applied in the direction of manufacturing tools, workpiece clamping devices, etc., can solve the problems of uneven clamping force, difficult loading and unloading, application restrictions, etc., and achieve uniform clamping force and high centering accuracy. , The effect of easy loading and unloading

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

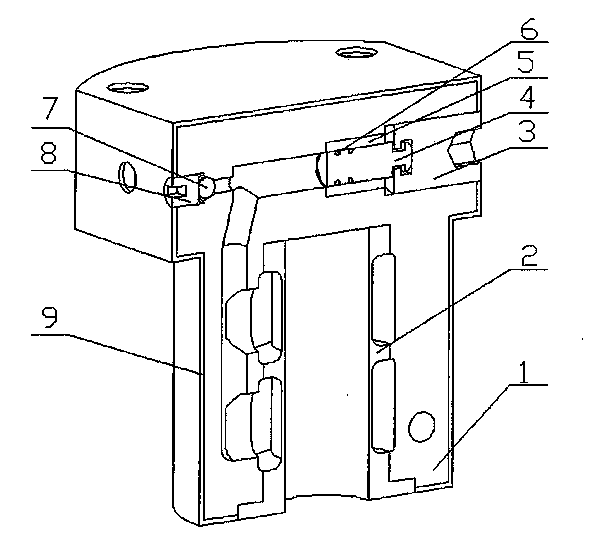

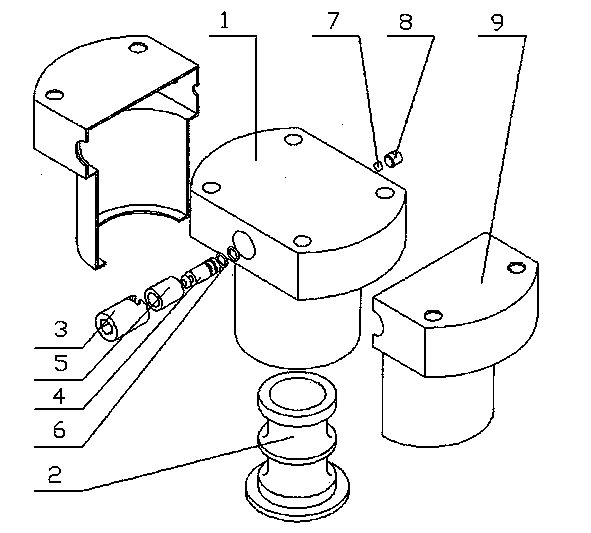

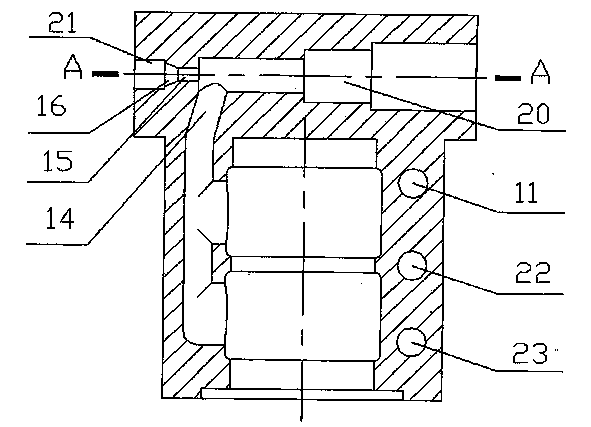

[0022] see figure 1 and figure 2 As shown, this embodiment is composed of a clamp body 1 with a non-standard flange 13, a thin-walled elastic sleeve 2, a screw bolt 3, a strut 4, a strut sleeve 5, a rubber sealing ring 6, a steel ball 7, a row The air screw 8 and the magnetic isolation sleeve 9 are composed, and the thin-walled elastic sleeve 2 is penetrated in the clamp body 1, and the shape of the thin-walled elastic sleeve 2 is as follows: Figure 6 As shown, the screwing bolt 3, the sliding column 4, the sliding column sleeve 5 and the rubber sealing ring 6 constitute a pressurizing device, the screwing bolt 3 is connected with the clamp body 1 through the thread pair, and the inner side of the screwing bolt 3 is connected with the hook device through the The sliding column 4 is connected, and the sliding column 4 is provided with a sliding column sleeve 5. There are two rubber sealing rings 6 on the sliding column 4, which play a sealing role. Screw the bolt 3, the slid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com