A solid wood floor core board rope threading machine

A solid wood floor and rope machine technology, applied in the field of floor manufacturing, can solve the problems of lower core board qualification rate and quality, easy detachment of connecting ropes, uneven long grooves, etc., achieve simple structure, improve qualification rate and quality, and simple operation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

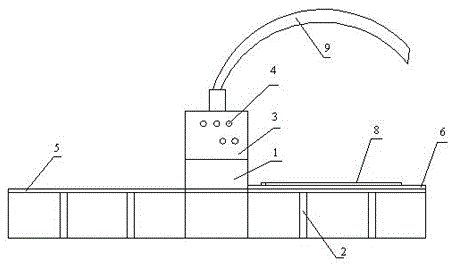

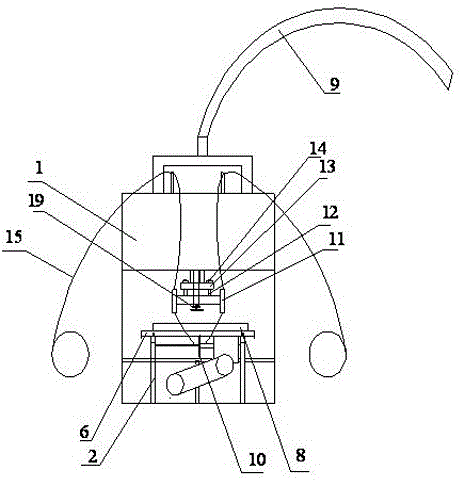

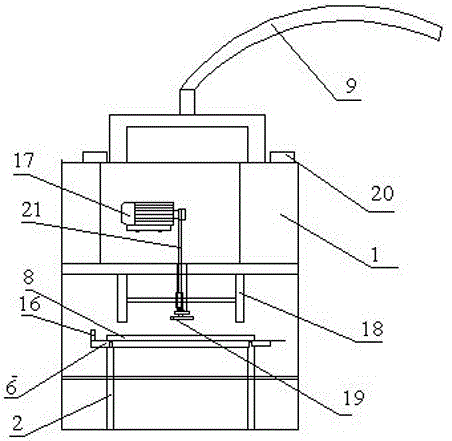

[0024] combine Figure 1-5 Description of this embodiment, a solid wood floor core board rope threading machine, including a gantry frame 1, a workbench 6, and a transmission device, the workbench 6 is installed under the gantry frame 1, and two A parallel guide rail 5, the guide rail 5 is fixed on the bracket 2, the worktable 6 is connected with the guide rail 5 through a pulley, and the transmission device drives the workbench 6 to perform reciprocating linear motion on the guide rail 5; the gantry frame 1 is provided with a grooving device, a connecting rope device, a pressing plate 19, and a control cabinet 3. The grooving device includes a grooving motor 17 and a saw blade 18. There are two saw blades 18. The grooving motor 17 drives the saw blade 18 to rotate the grooving; the control cabinet 3 is connected with the grooving motor 17 and the transmission device, and the control cabinet 3 is provided with a control button 4; the connecting rope device includes two pressur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com