Mechanical cutting device for ceramic blanks

A technology for mechanical cutting and ceramic blanks, applied in ceramic molding machines, work accessories, stone processing tools, etc., can solve the problems of low output, damage, and inability to improve cutting quality in a large area, so as to improve cutting accuracy and reduce damage. , the effect of improving the artistic level

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

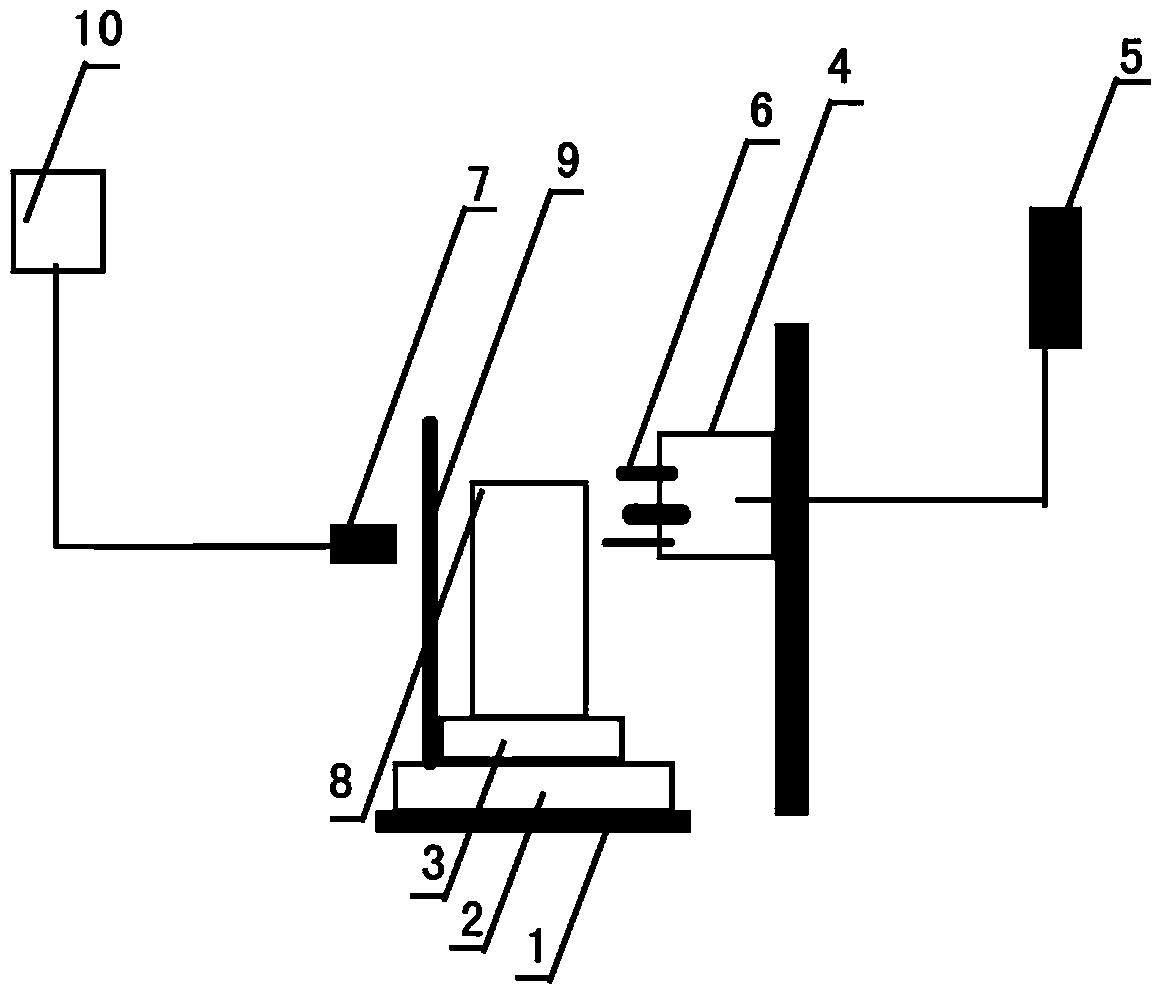

[0012] Embodiment: as shown in the accompanying drawing. The mechanical cutting device for ceramic blanks includes a base 1, on which a speed-regulating motor 2 is set, and a ceramic placing table 3 is set on the speed-regulating motor 2; Cutters 6 with different cutting structures are set on the disc 4, and a monitoring device 7 is set on the side of the cutting tool disc 4, and the data of cutting processing is input into the numerical control control module 5, and the ceramic body 8 is placed on the ceramic display table 3, and the cutter 6 is set according to the setting. The program cuts the ceramic body, and monitors the cutting process through the monitoring device 7 .

[0013] The mechanical cutting device of the ceramic blank is provided with a transparent separating plate 9 in front of the monitoring device 7 .

[0014] The mechanical cutting device of the ceramic blank is equipped with a prompting device 10 to prompt the progress status of the cutting process.

[...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com