Hook arm of buffer load-shedding arresting hook

A technology of arresting hooks and hook arms, which is applied in the direction of lightning arrester hooks, fluid pressure actuating devices, launching/dragging transmissions, etc., can solve the problems of reducing aircraft combat performance, not having the function of buffering and reducing load, and increasing structural weight, etc., to achieve The effect of simple structure, stable working performance and easy implementation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

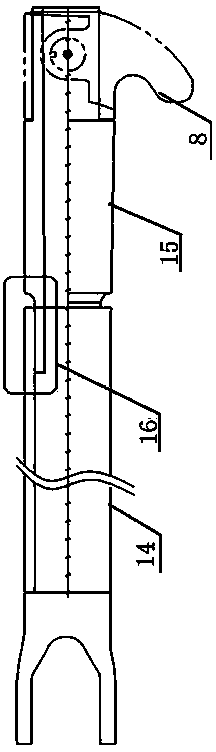

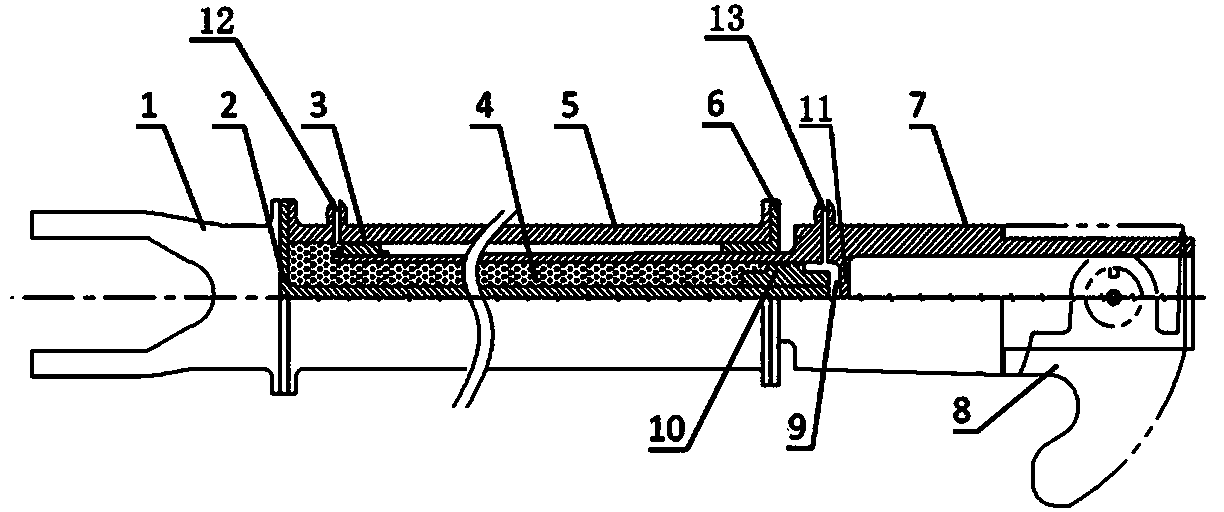

[0015] Example: see figure 2 .

[0016] The invention discloses a buffer and load reduction arresting hook arm, such as figure 2 As shown, one end is a joint 1, and the other end is a hook head 8. Between the joint 1 and the hook head 8, there are an outer cylinder 5 and an inner cylinder 7 in sequence, and the main body of the inner cylinder 7 is large at one end and small at the other. Hollow stepped columnar structure, the main body of the outer cylinder 5 is a hollow columnar structure, the small end of the inner cylinder 7 extends into the outer cylinder 5, and also includes a core rod 2, one end of the core rod 2 is connected to the connector 1 and the outer cylinder 5 The outer end is tightly connected, and the other end extends into the interior of the inner cylinder 7. There is a gap between the outer surface of the small end of the inner cylinder 7 and the inner surface of the outer cylinder 5, and the outer fixed sleeve of the small end of the inner cylinder 7 is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com