Method used for changing surfaces of black tourmaline powder into red

A tourmaline powder, red technology, applied in the field of chemistry, can solve problems such as limiting the scope of application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

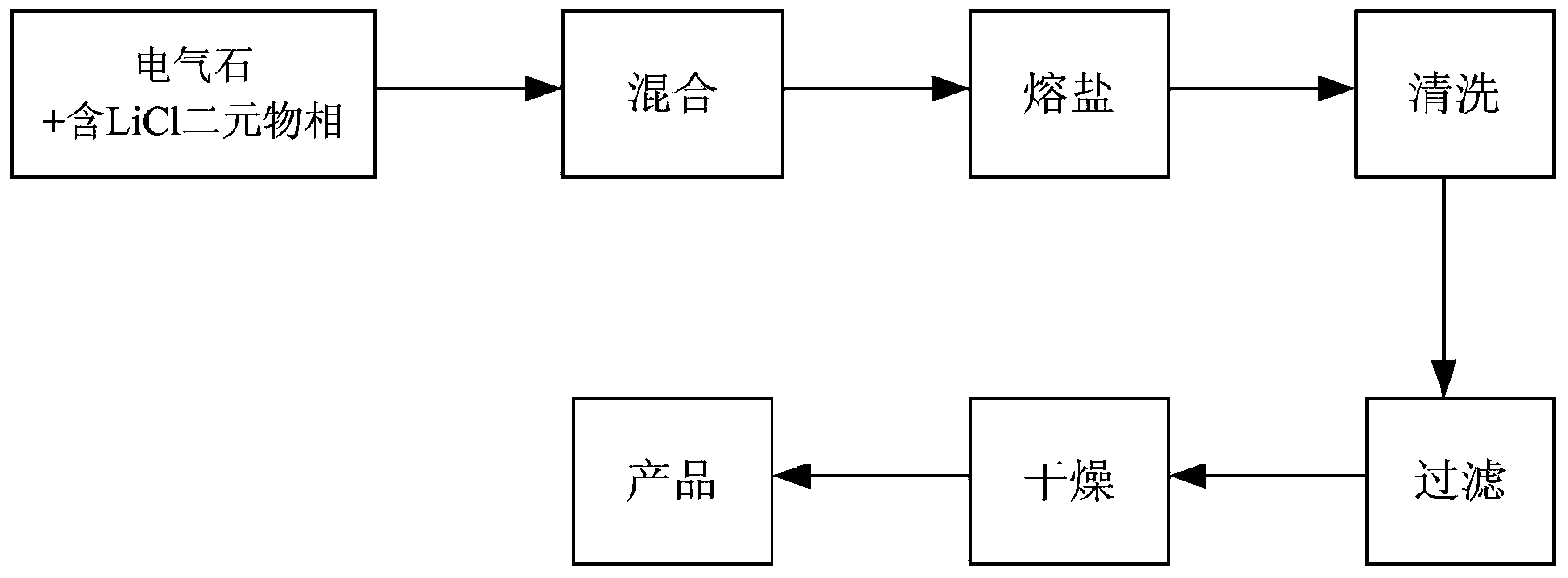

Image

Examples

Embodiment 1

[0017] Use 325 mesh tourmaline powder and LiCl-CaCl 2 (LiCl accounts for 20% to 40% by weight, CaCl 2 60% to 80% by weight) or LiCl-KCl (30% to 50% by weight of LiCl, 50% to 70% by weight of KCl) binary solid solution phase mixed at a weight ratio of 1:1 Evenly; put it into a crucible resistance furnace, heat to 500-800°C, keep it warm for 4 hours, cool, wash, and dry to obtain a red Li with a lightness value L* of 28-38 and a "reddening" degree a* value of 5-14. -tourmaline.

Embodiment 2

[0019] Use 325 mesh tourmaline powder and LiCl-CaCl 2 (LiCl accounts for 20% to 40% by weight, CaCl 2 60% to 80% by weight) or LiCl-KCl (30% to 50% by weight of LiCl, 50% to 70% by weight of KCl) binary solid solution phases are mixed evenly at a weight ratio of 1:1 Put it into a crucible resistance furnace, heat it to 500-750°C, keep it warm for 8 hours, cool, wash, and dry to obtain a red Li- tourmaline.

Embodiment 3

[0021] Use 325 mesh tourmaline powder and LiCl-CaCl 2 (LiCl accounts for 20% to 40% by weight, CaCl 2 60% to 80% by weight) or LiCl-KCl (30% to 50% by weight of LiCl, 50% to 70% by weight of KCl) binary solid solution phases are mixed in a weight ratio of 1:1 Uniform; put it into a crucible resistance furnace, heat to 500-700°C, keep warm for 24 hours, cool, wash, and dry to obtain a red Li with a lightness value L* of 29-38 and a "reddening" degree a* value of 4-12 -tourmaline.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com