Mechanical stereo garage and automobile conveying method thereof

A three-dimensional garage, mechanical technology, applied in the direction of the buildings, building types, buildings, etc. where cars are parked, can solve the problems of large rotation space of the turntable, the impact of land utilization, and the longer access time, so as to reduce equipment costs. , reduce the point of failure, improve the effect of land utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

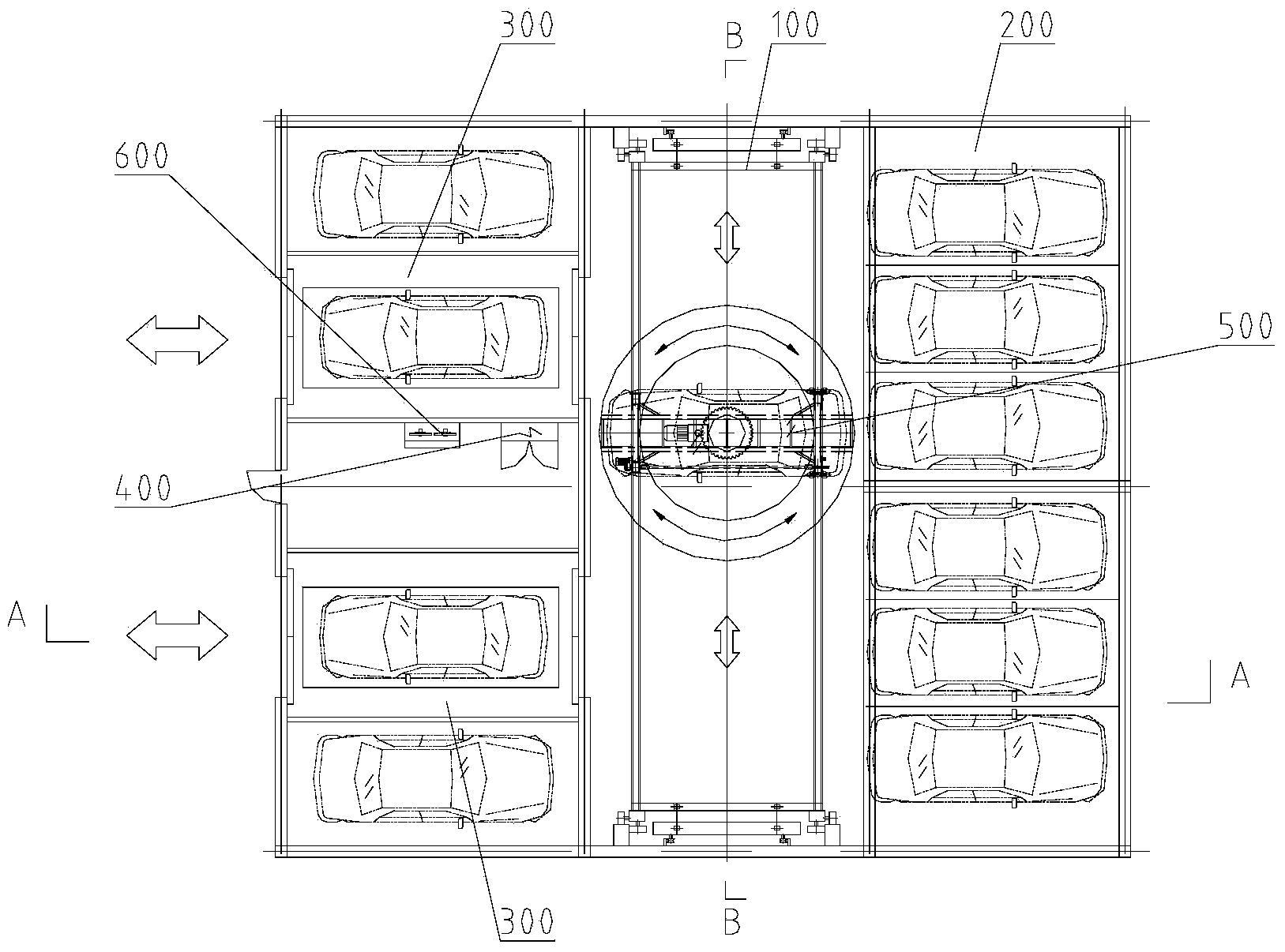

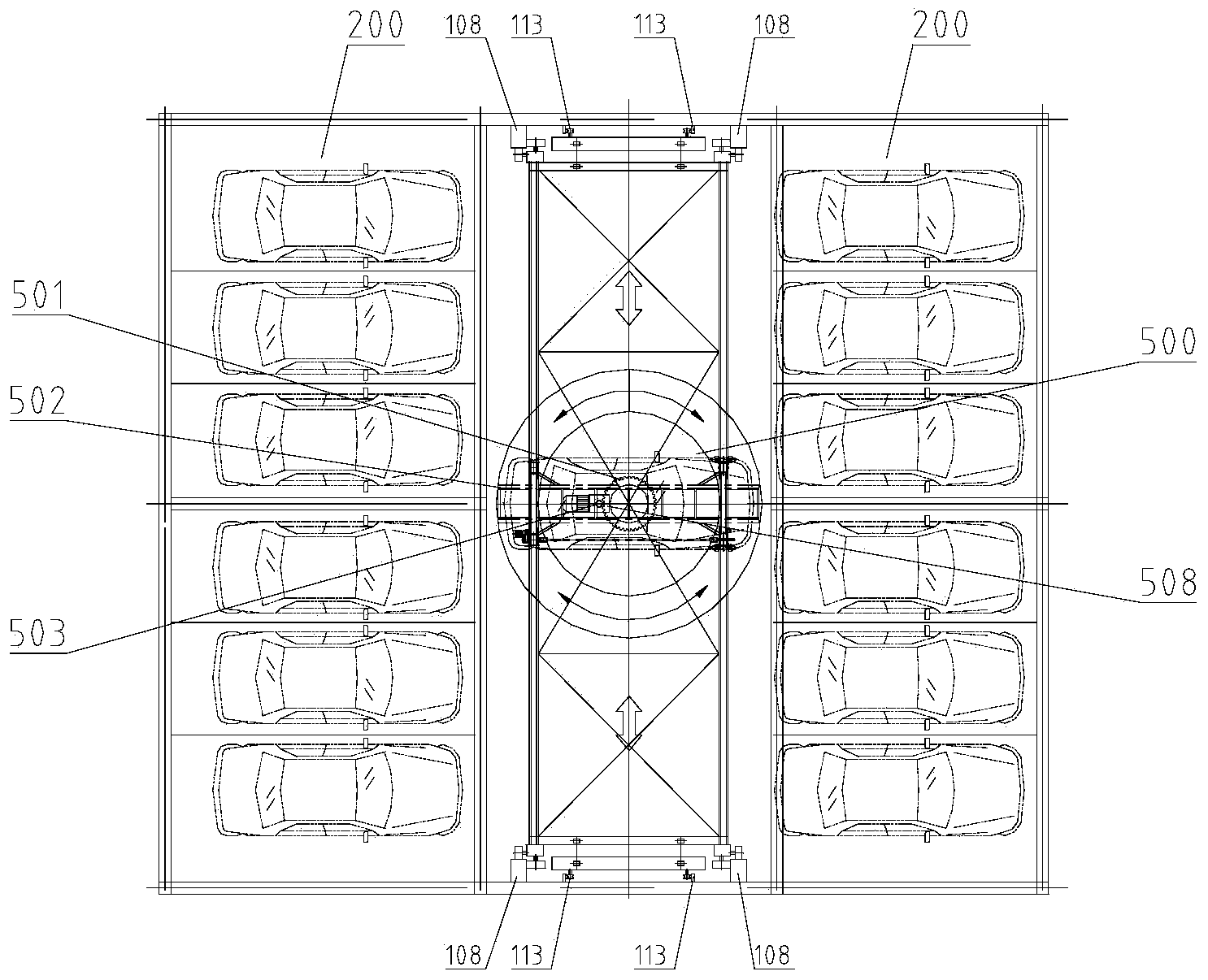

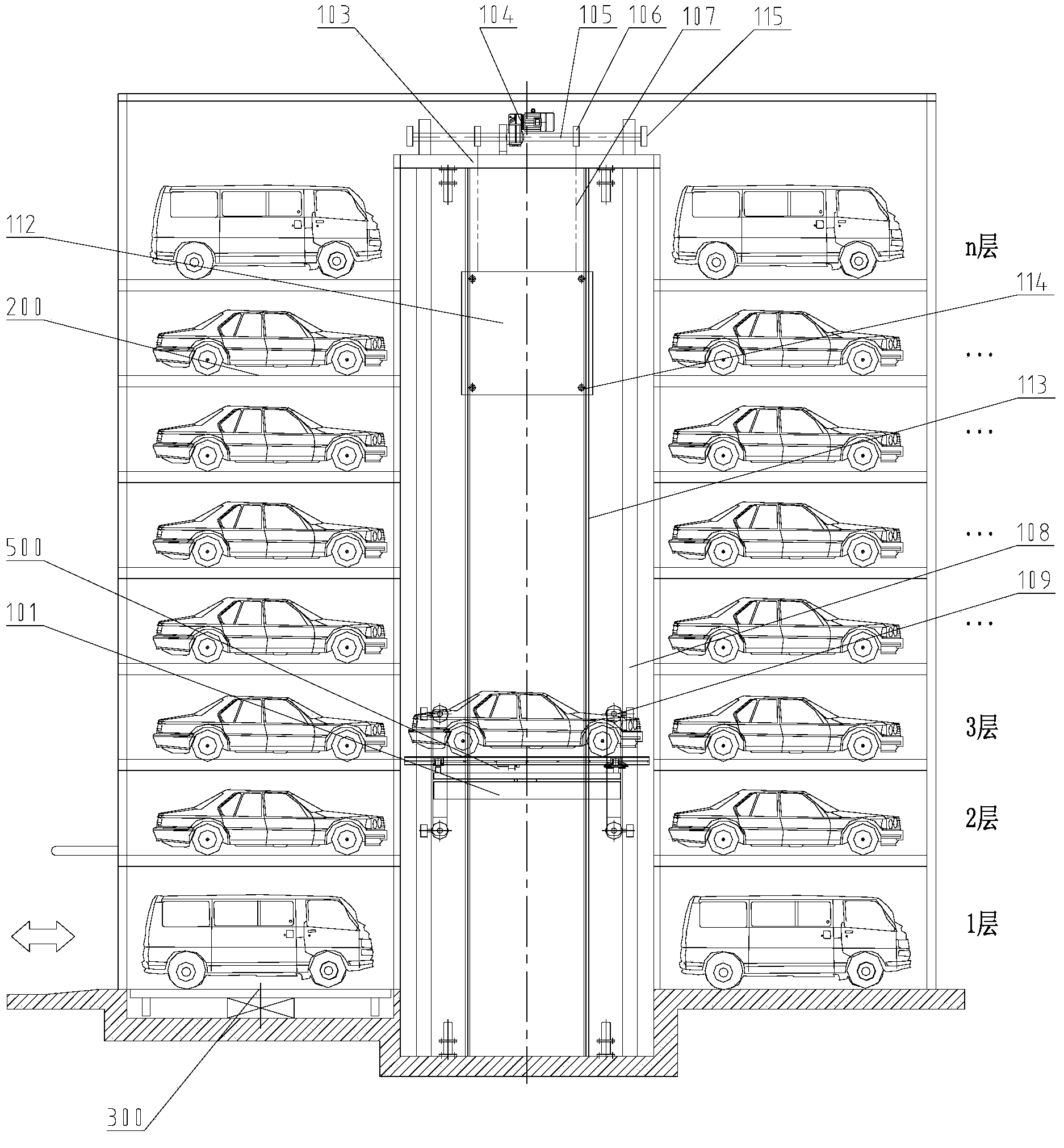

[0027] In a preferred embodiment, it relates to a comb exchange type novel vertical lifting class three-dimensional parking garage, such as Figure 1 to Figure 4 As shown, the garage includes a lifting system 100 , a multi-storey parking space 200 , an entry and exit room 300 , an electric control room 400 , a rotary and traverse system 500 and a garage control system 600 . In the middle of the steel skeleton of the garage, there is a middle roadway for vertical lifting of the lifting system 100. The middle roadway is a cuboid structure, and multi-storey parking spaces 200 are distributed on both sides of the narrow and long orientation. The entry and exit warehouse 300 is arranged on the bottom floor of the garage, and the rotary and lateral movement system 500 is arranged on the lifting platform 101 of the lifting system 100. The rotary and lateral movement system 500 is provided with a carrier access car running track; Each parking space is provided with a carrier running t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com