Completion and fracture integrated pipe column of offshore openhole horizontal well and construction method of pipe column

A technology of completion string and construction method, which is applied in wellbore/well components, production fluids, earth-moving drilling, etc., can solve the problems that the technology cannot meet the requirements of refined reservoir reconstruction and cannot fully adopt fracturing construction. , to achieve good economic benefits, simple structure, and reduce the accident rate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] In order to make the purpose of the invention, technical solutions and beneficial effects of the present invention clearer, the embodiments of the present invention will be described below in conjunction with the accompanying drawings. The features in can be combined arbitrarily with each other.

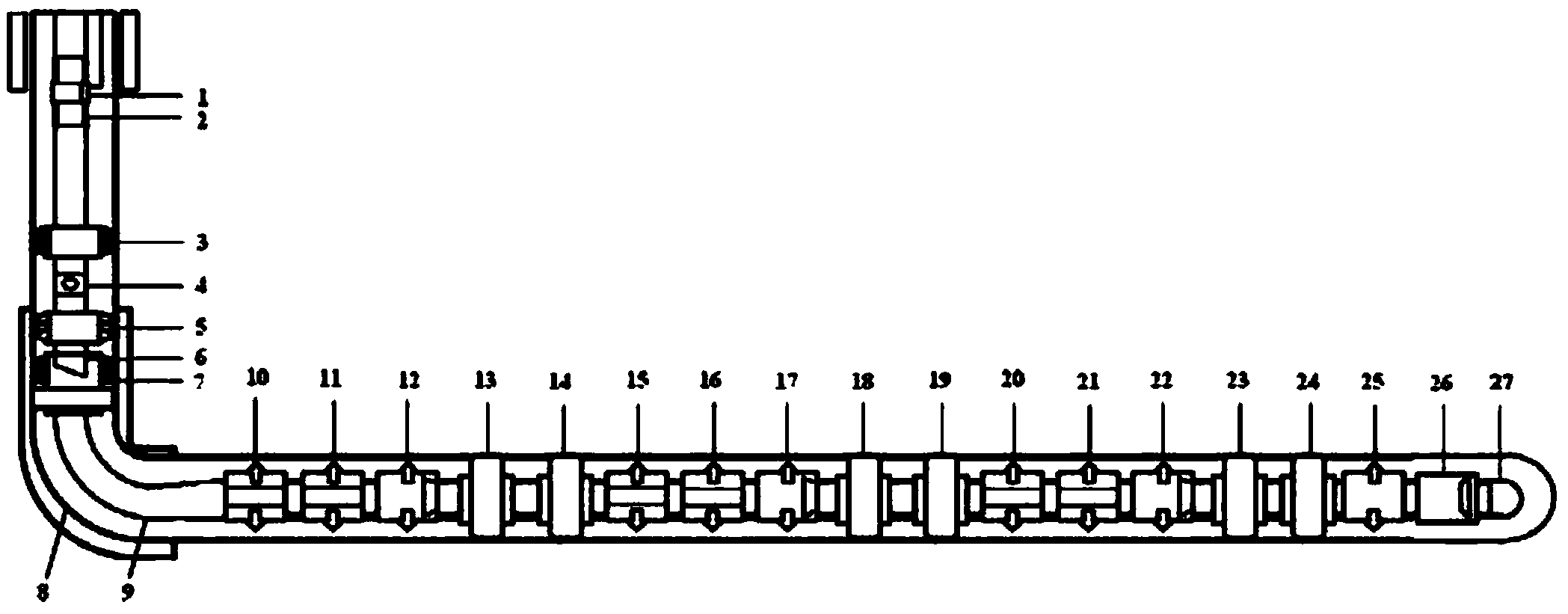

[0043] figure 1 It is a schematic diagram of the connection of integrated fracturing strings for offshore open-hole horizontal wells. Such as figure 1As shown, an offshore open-hole horizontal well completion and fracturing integrated string includes a casing 8, a bottom completion string and a top tie-back string, and the bottom completion string and the top tie-back string are both located in the casing 8, the bottom completion string includes a four-stage fracturing construction group connected to the hanging packer 7 and a floating shoe 27 located at the front end of the tubing 9. connected in series, the top tie-back string includes a tie-back tubing and an anchor inse...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com