Dust offline sampling system in closed loop type high-pressure natural gas pipeline and sampling method thereof

A natural gas pipeline and sampling system technology, which is applied in the field of solid dust collection and analysis in pipelines, can solve problems such as aggravating environmental pollution, waste of natural gas, and increasing potential safety hazards in the field sampling process, so as to reduce environmental pollution, ensure no backflow, and meet testing requirements. Effects of precision requirements and safety requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] In order to have a clearer understanding of the technical features, purposes and effects of the present invention, the specific implementation manners of the present invention will now be described with reference to the accompanying drawings.

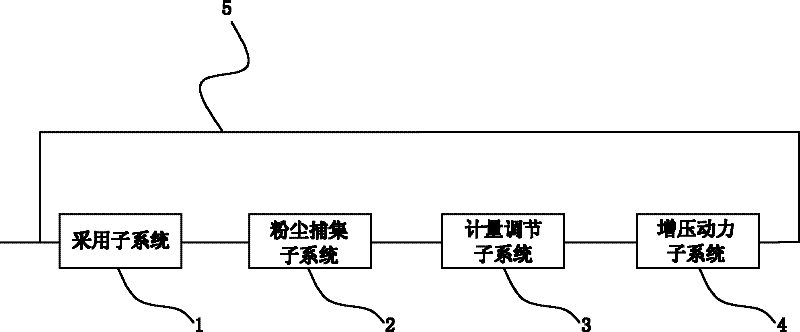

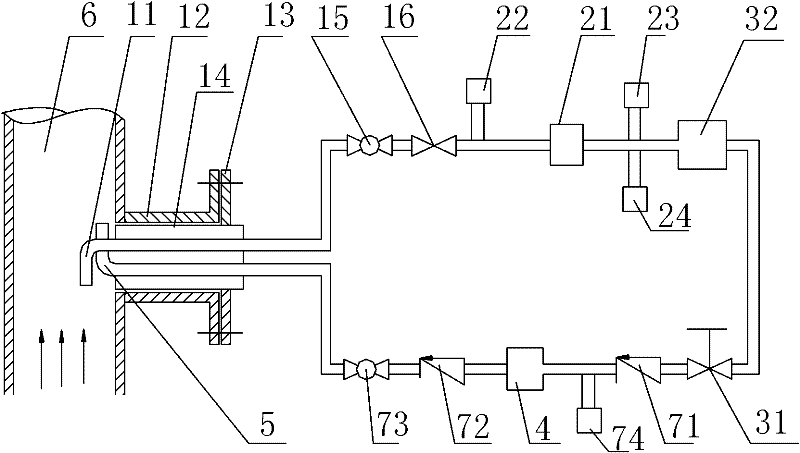

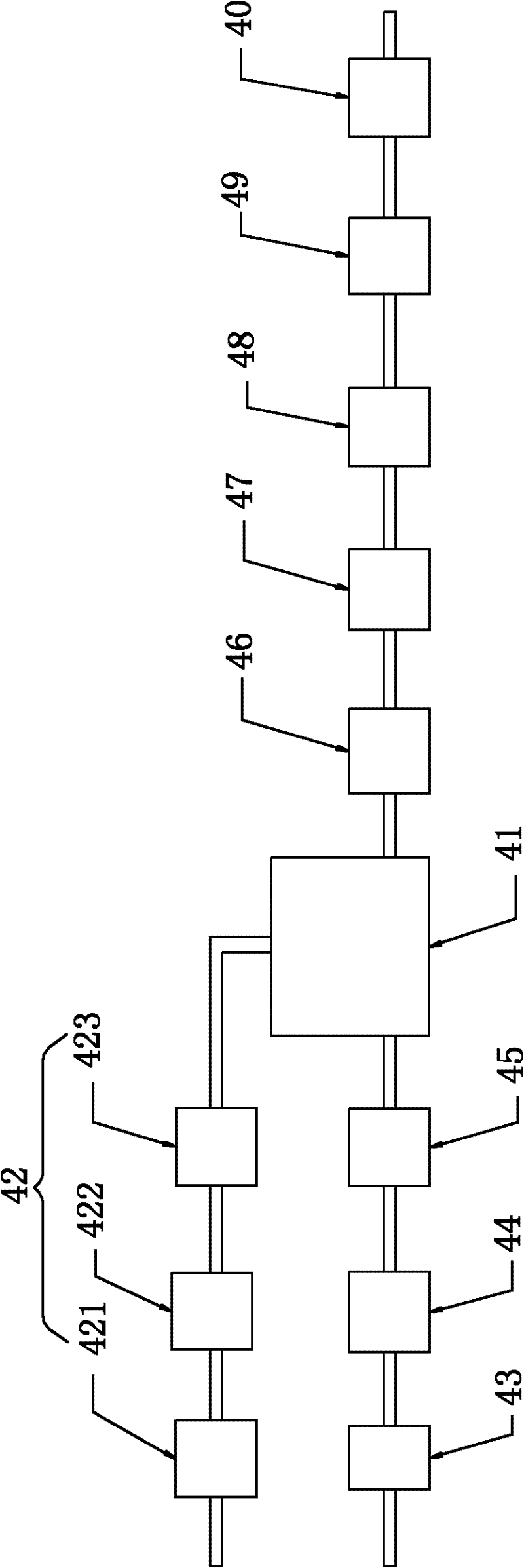

[0043] Please refer to figure 1 , figure 2 , are respectively the structural block diagram and structural schematic diagram of the off-line dust sampling system in the closed-loop high-pressure natural gas pipeline of the present invention. As shown in the figure, the closed-loop high-pressure natural gas pipeline dust off-line sampling system of the present invention includes a sampling subsystem 1, a dust collection subsystem 2, a metering adjustment subsystem 3, and a pressurized power subsystem connected in series through the pipeline. 4. The output end of the pressurized power subsystem 4 is connected to one port of the return pipeline 5, and the other port of the return pipeline 5 extends into the high-pressure natural ga...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com