Vertical material tumble dryer

A technology for dryers and materials, applied in the direction of dryers, drying, drying chambers/containers, etc., can solve the problems of affecting the full contact between hot air and materials, waste of energy, and low drying efficiency, so as to speed up, The effect of improving production efficiency and improving utilization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

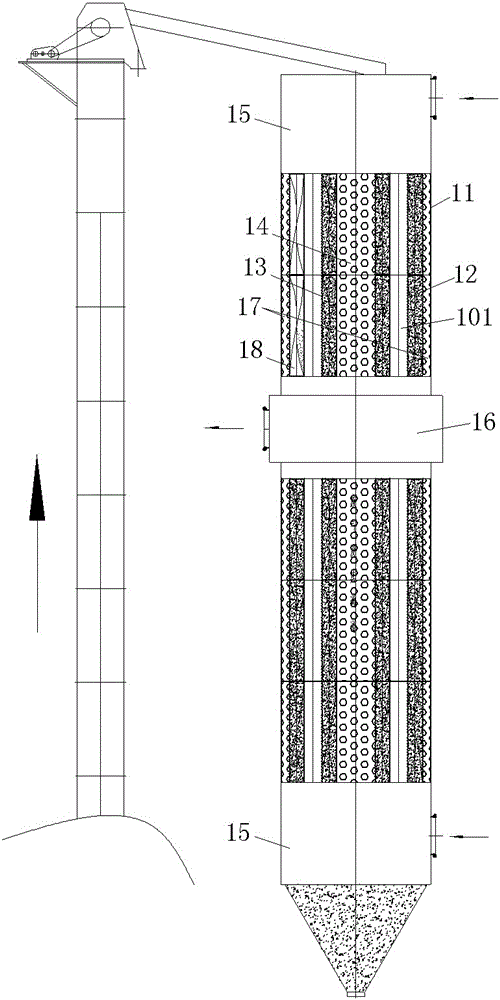

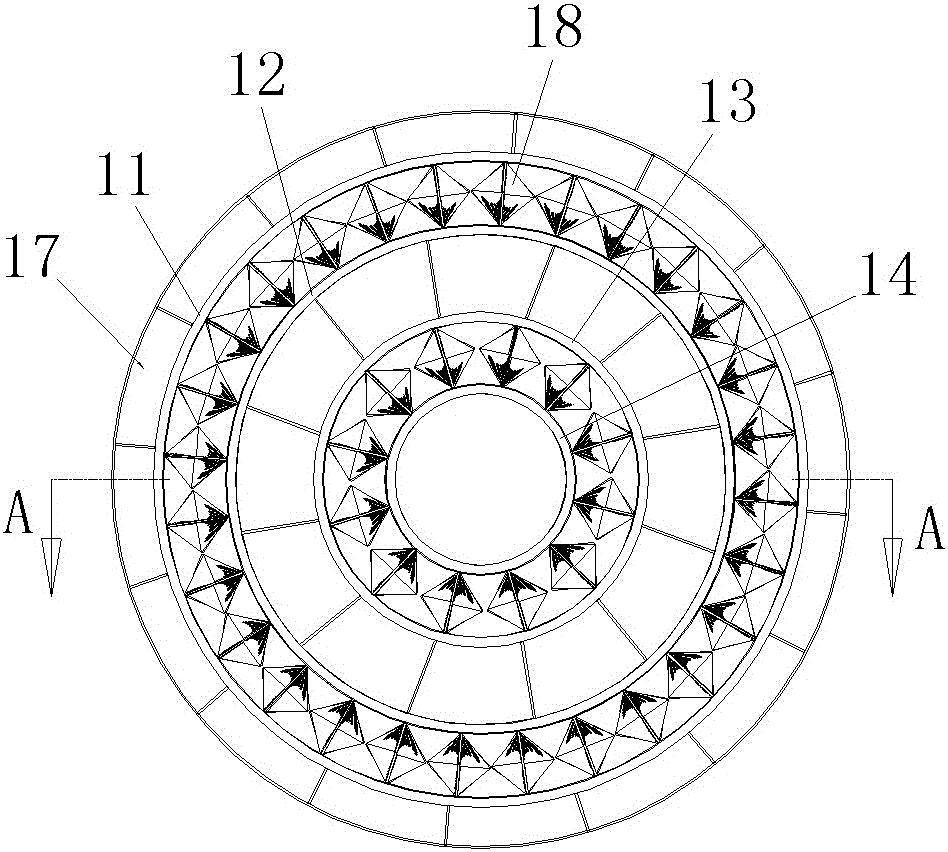

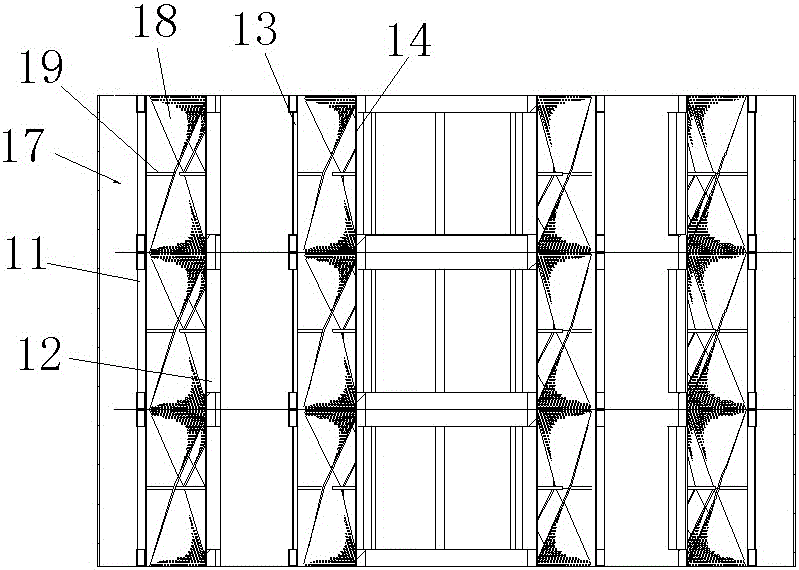

[0024] Examples of vertical material tumble dryers, such as Figure 1-5 As shown, the vertical material tumbling dryer includes two layers of drying units arranged coaxially from the outside to the inside, and each layer of drying units includes an outer cylinder and an inner cylinder. For the distinction of dry units, the outer and inner cylinders of the outer drying unit are called the outer outer cylinder 11 and the outer inner cylinder 12, and the outer and inner cylinders of the inner drying unit are called the inner outer cylinder Body 13, inner cylinder 14. In addition, the top and bottom of the dryer are respectively provided with air-introducing ducts 15, which are used to introduce hot air into the dryer, and the middle part of the dryer is provided with waste gas ducts 16, the air-introducing ducts and the exhaust air ducts They are all composed of air bags, and the exhaust gas pipeline 16 is used to centrally collect the exhaust gas in the dryer and discharge it u...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com