Calibration Structure and Calibration Method of Thermal Overload Relay Tripping Distance

A thermal overload relay and calibration method technology, applied in the field of low-voltage electrical appliances, can solve the problems of poor calibration accuracy and low qualification rate of calibration methods, and achieve the effect of convenient calibration and avoidance of service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] In the following, the present invention will be further described by using the following embodiments in conjunction with the accompanying drawings.

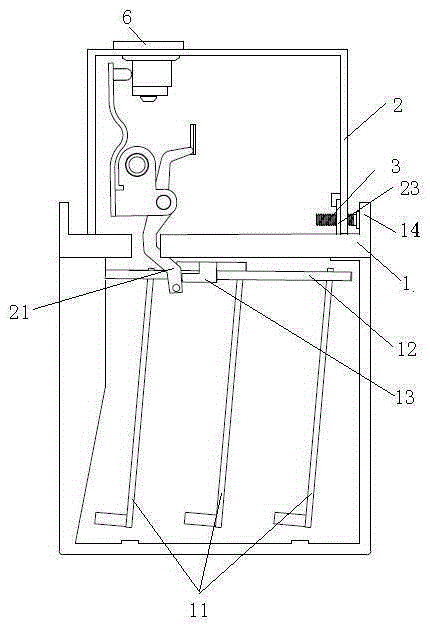

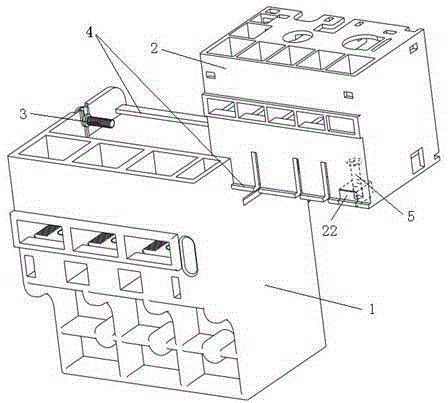

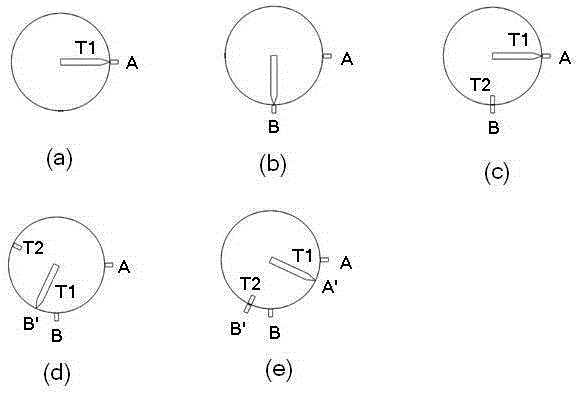

[0032] figure 1 , figure 2 It is a calibration structure for the tripping distance of a thermal overload relay disclosed in the present invention, which includes a housing 1, a bimetal 11 is provided in the housing 1, and a guide plate is provided on the bimetal 11 of the three phases, The guide plate 12 is provided with a differential lever 13; a base 2, a release lever 21 cooperating with the differential lever 13 is arranged in the base 2; the base 2 is slidably connected to the shell On the body 1, an adjustment member 3 is provided between the base 2 and the housing 1, and an indicator mark is provided on the adjustment member 3; the adjustment member 3 is suitable for adjusting the relative position of the base 2 to the The sliding distance of the housing 1 can further realize the relative change of the distance b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com