Method for predicting leakproofness assembling quality of remanufactured cylinder heads of automobile engines

A technology for automobile engine and quality prediction, which is applied in the field of prediction and achieves significant technical and economic effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] 1. The comprehensive uncertainty of each cylinder head air hole in different batches

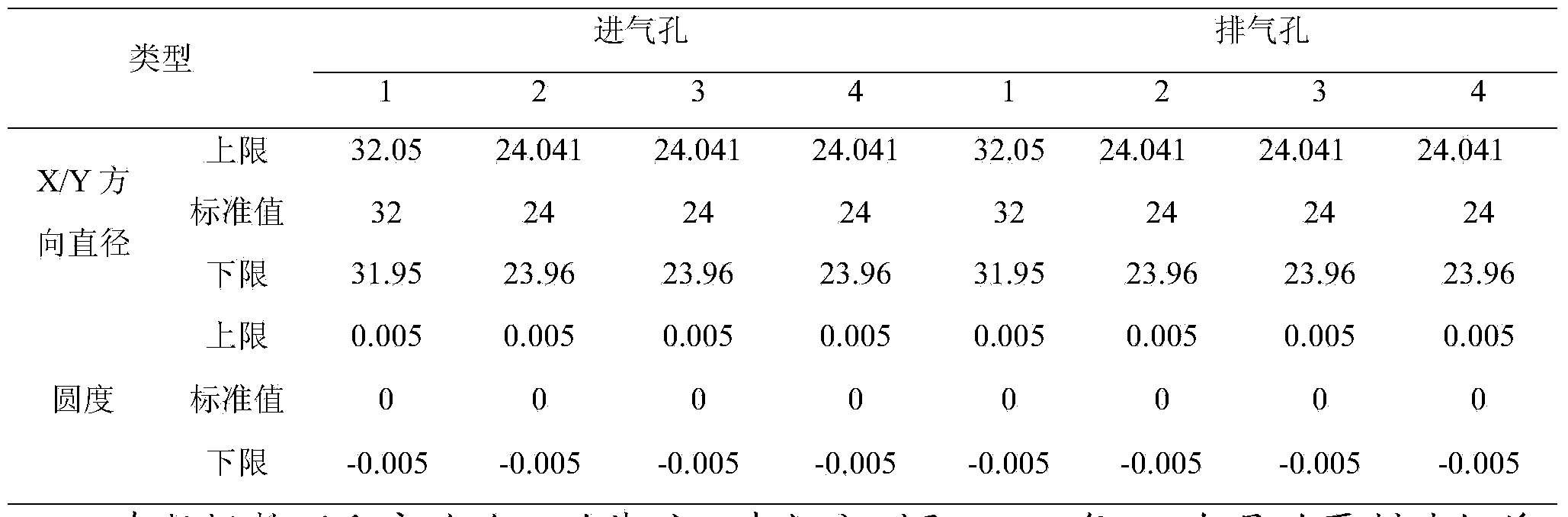

[0031] The quality standards for intake and exhaust holes of remanufactured cylinder heads provided by the Engine Technology Center are shown in the table below:

[0032]

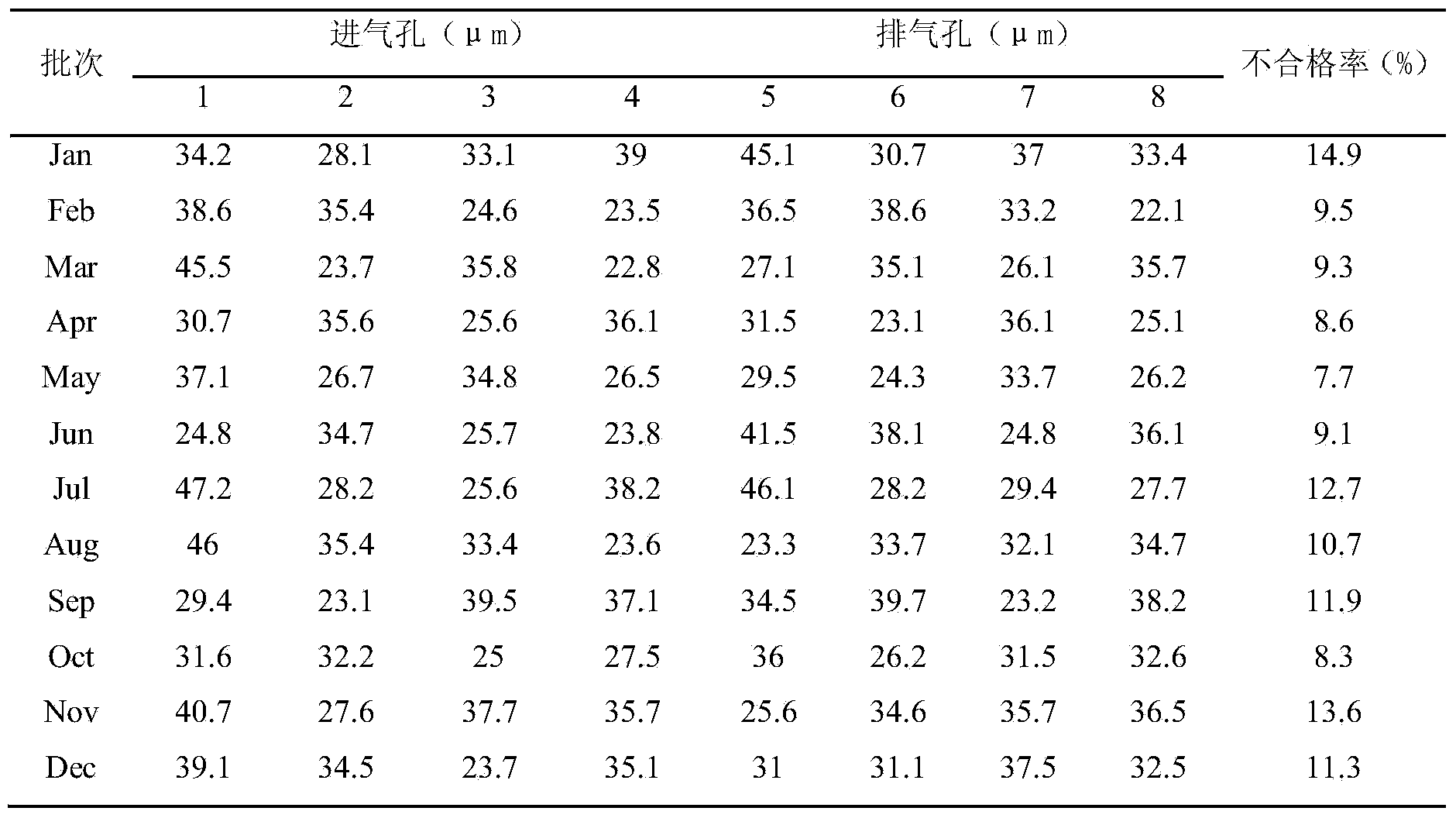

[0033] On the basis of data collation and experimental verification, we took the research data of the uncertainty of the remanufactured cylinder head and the first-time assembly pass rate in 12 months of 2012. Among them, this type of cylinder head has a total of 8 air holes, 4 air intake holes and 4 exhaust holes. According to the roundness, longitudinal and transverse diameter information of the intake and exhaust holes of the remanufactured cylinder head. The average comprehensive uncertainty of each hole of each batch of cylinder head is calculated by the formula.

[0034]

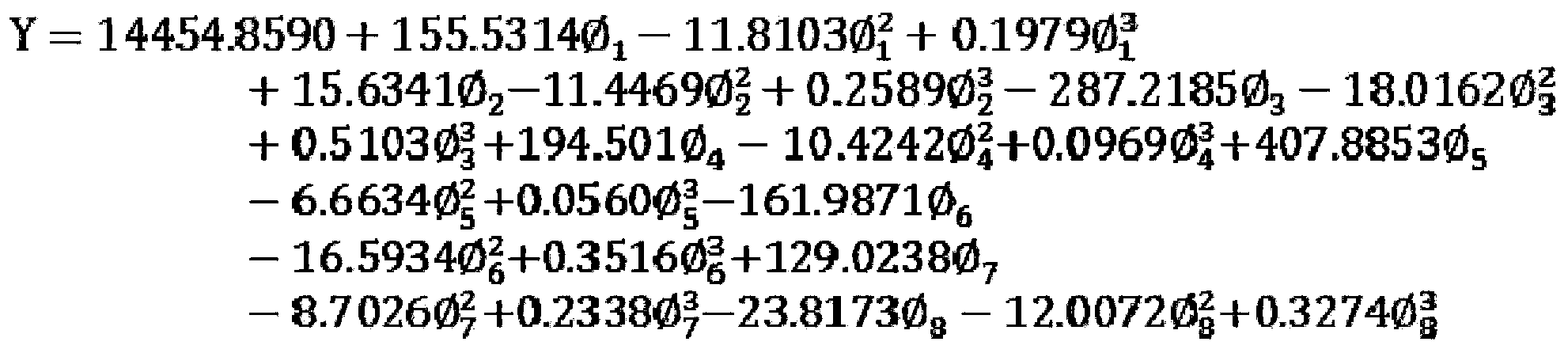

[0035] 2. Establishment of nonlinear model and solution

[0036] Since the impact of the comprehensive uncertainty of each cylind...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com