TV test tooling plate

A tooling board and substrate technology, which is used in TV, electrical components, image communication, etc., can solve the problems of inability to meet production and processing, complex structure of tooling boards, and troublesome packaging and transportation of tooling boards, and achieve flexible packaging and transportation. The effect of occupying space and simple overall structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] Below in conjunction with accompanying drawing, the specific embodiment of the present invention will be described in further detail, and the following examples are used to illustrate the present invention, but are not used to limit the scope of the present invention.

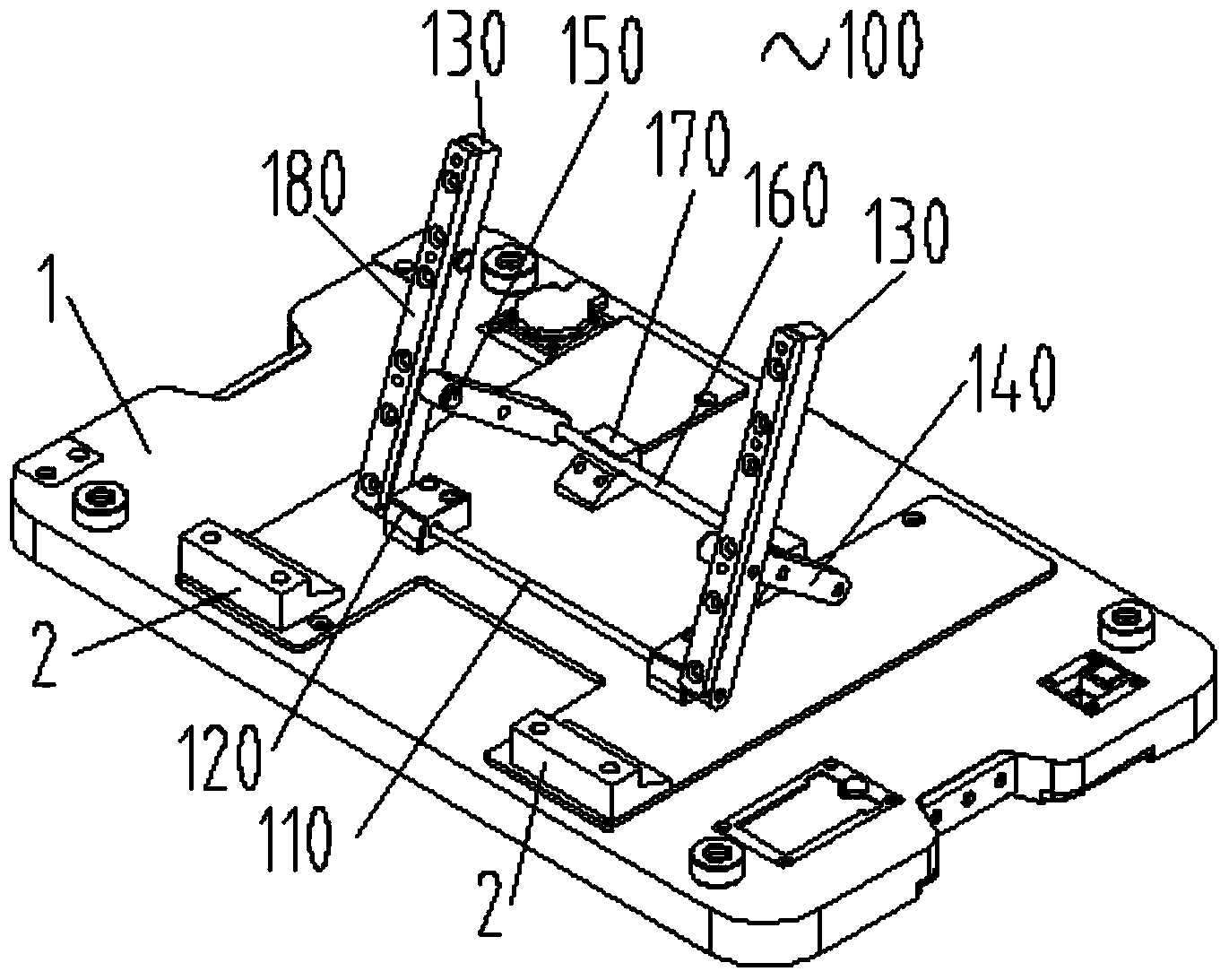

[0015] as attached figure 1 As shown in the TV test tooling board, the tooling board includes: a base plate 1, a limit block 2 is arranged on the base plate 1, and a bracket mechanism 100 is arranged at a preset distance from the limit block 2, and the bracket mechanism 100 is Including: the rotating shaft 110, the rotating shaft 110 is connected with the base plate 1 through the shaft seat 120, the rotating shaft 110 can rotate around the joint between the rotating shaft 110 and the shaft seat 120, and the two sides of the rotating shaft 110 are respectively provided with a backing plate 130, the backing A support rod 140 is provided below the board 130, and the support rod 140 is connected with the bac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com