Fe-based amorphous alloy, and dust core obtained using Fe-based amorphous alloy powder

A powder magnetic core and alloy powder technology, which is applied in the manufacture of inductors/transformers/magnets, magnetic materials, magnetic objects, etc., can solve the problem that Fe-based amorphous alloys cannot have a glass transition temperature, are not disclosed, and cannot be obtained. Saturation magnetic flux density and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

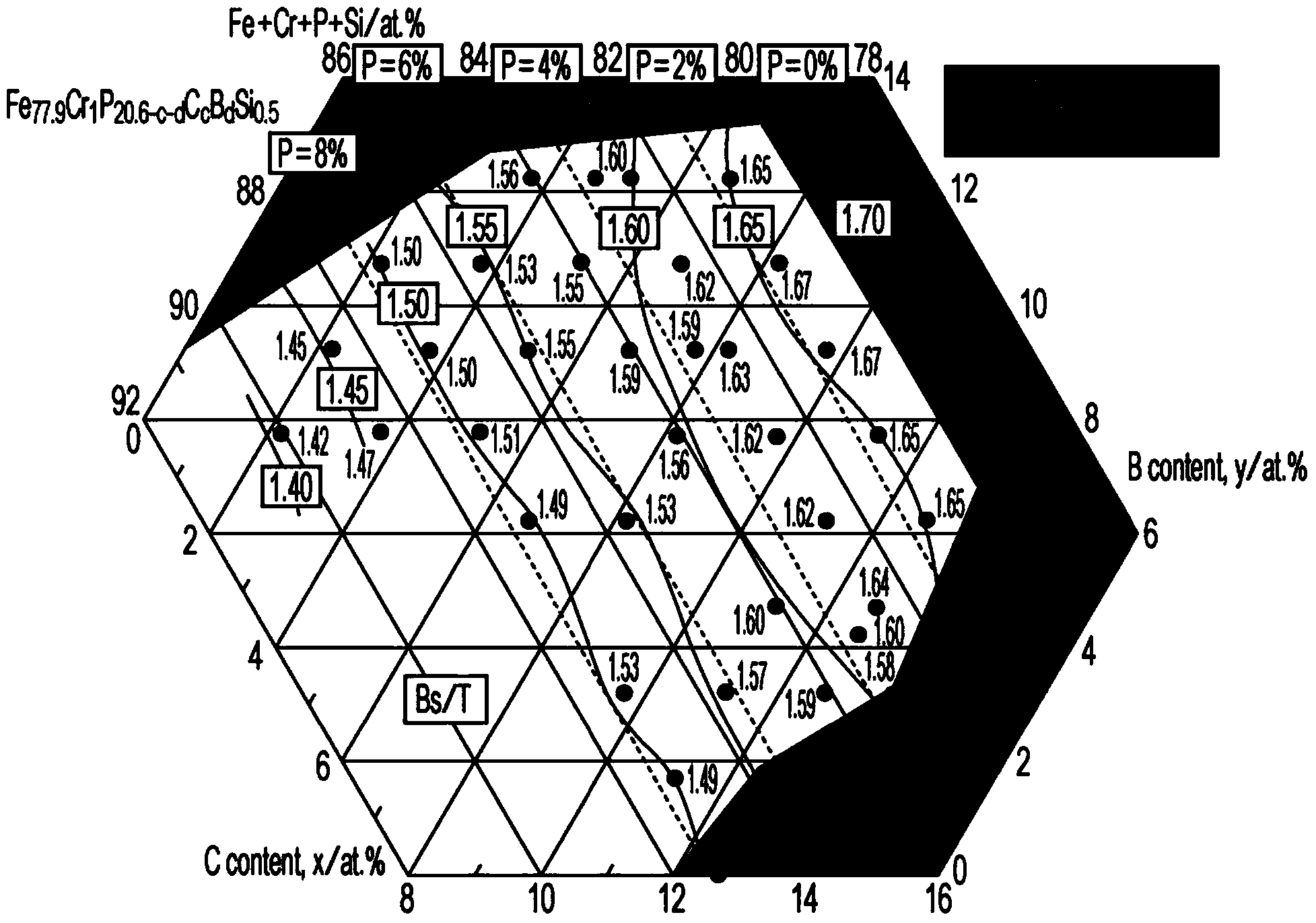

[0076] (Experiment of saturation magnetic flux density Bs and other alloy characteristics: liquid quenching method)

[0077] Hereinafter, Fe-based amorphous alloys having the compositions in Table 1 were produced in a ribbon shape by a liquid quenching method. Specifically, the belt was obtained under a reduced-pressure Ar atmosphere by a single-roll method in which a melt of Fe-Cr-P-C-B-Si was ejected from a nozzle of a crucible onto a rotating roll and quenched. method. As belt manufacturing conditions, the distance (gap) between the nozzle and the roller surface is set to about 0.3mm, the peripheral speed of the roller is set to about 2000m / min, and the injection pressure is set to 0.3kgf / cm 2 about.

[0078] The plate thickness of each obtained tape was about 20 to 25 μm.

[0079] [Table 1]

[0080]

[0081]

[0082]

[0083] It was confirmed by XRD (X-ray diffraction apparatus) that each sample in Table 1 was amorphous (amorphous). In addition, Curie tempera...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com