Peripheral transmission sludge suction method and suction dredge adopting gas stripping device

A technology of peripheral transmission and sludge suction machine, which is applied in the direction of the feeding/discharging device of the settling tank, etc., can solve the problems of large amount of sludge accumulated in the secondary sedimentation tank and weak mud suction ability, and achieve simple equipment structure and power equipment. Effect of less and enhanced sludge suction capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

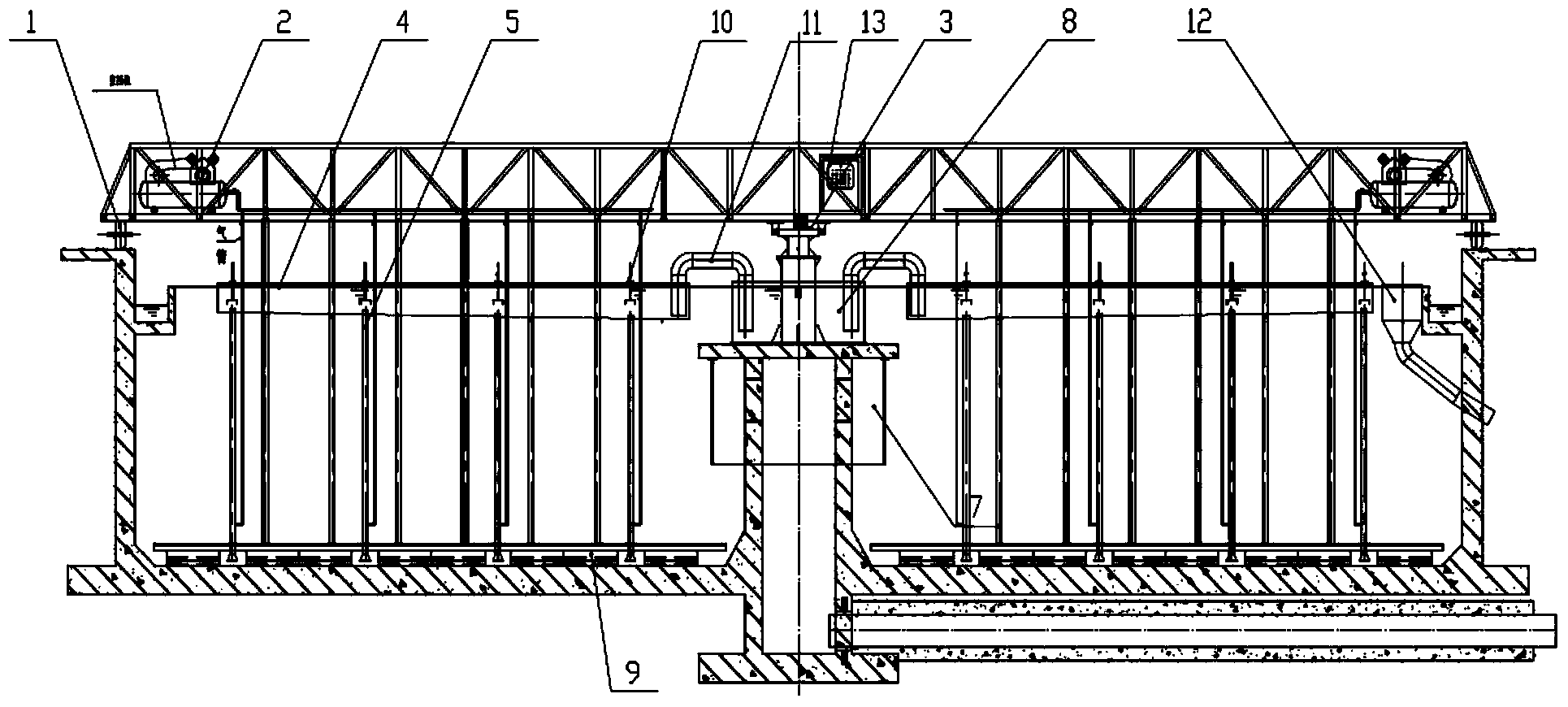

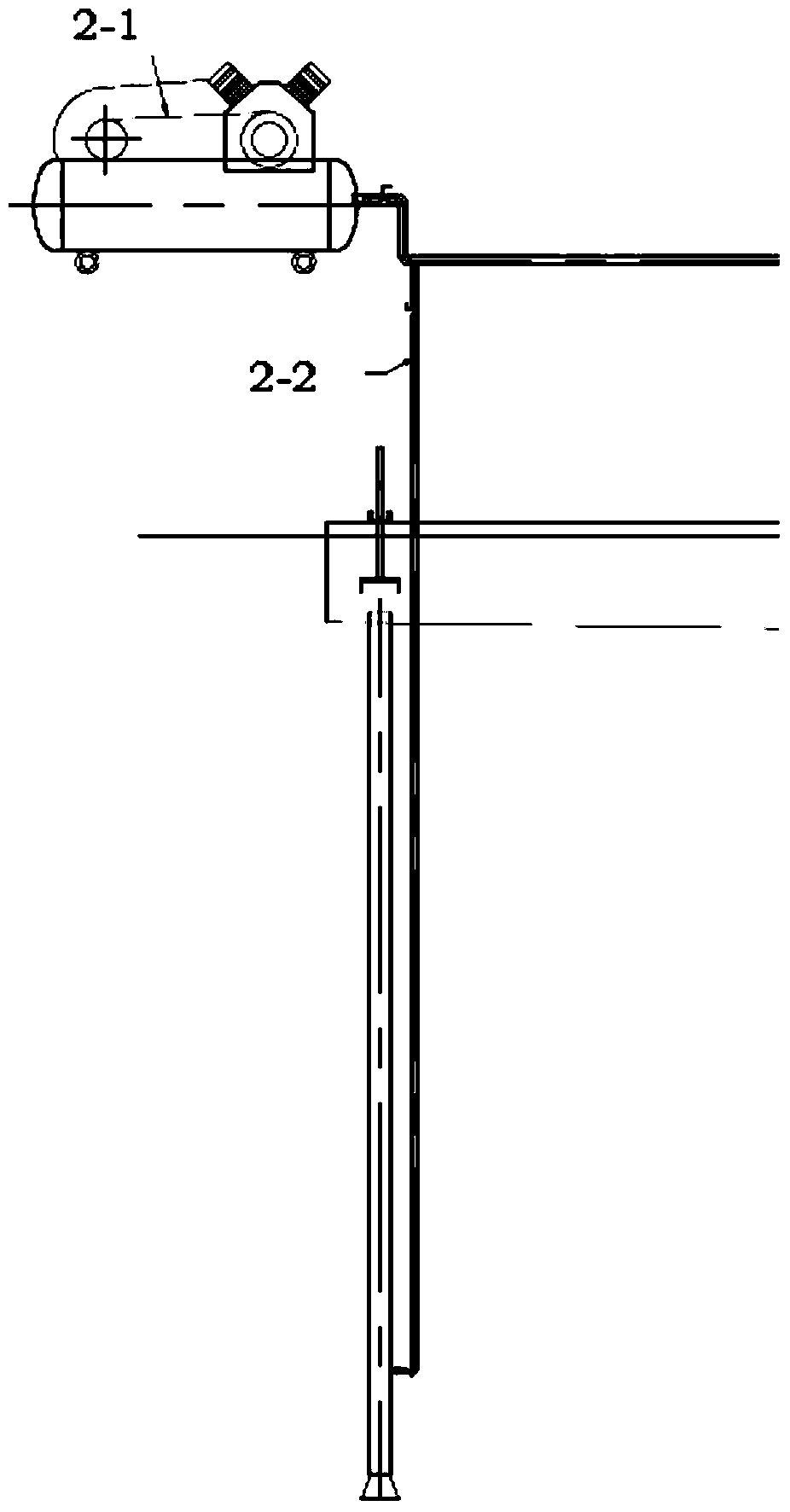

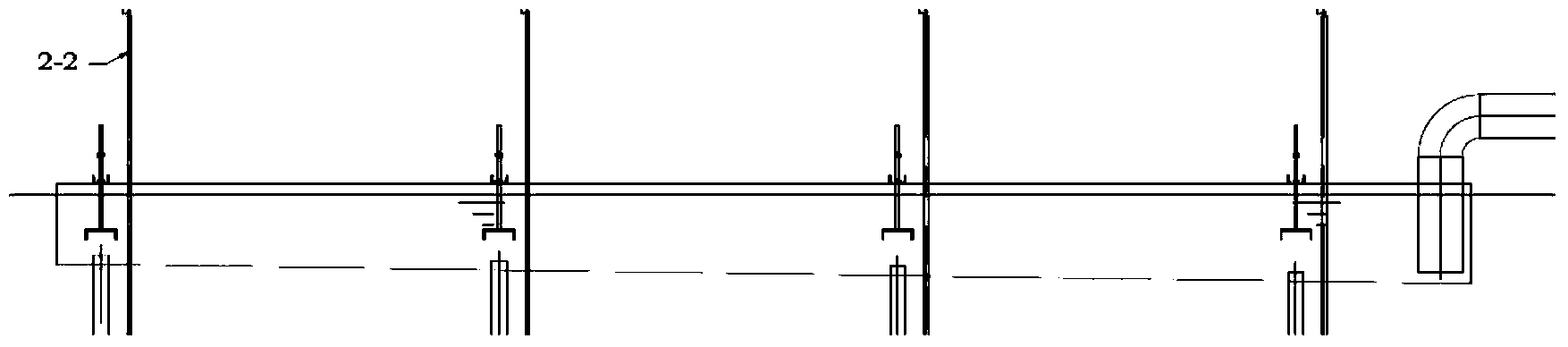

[0023] Equipped with an air lift device, the peripheral transmission mud suction machine adopts the peripheral drive device (1), adopts the central fixed shaft (3) and rotates in a circle with (3) as the center of the circle; the sludge enters from the bottom pipe of the sedimentation mud, and is passed through the central steady flow cylinder (7), evenly enters the sedimentation tank, and the central steady flow cylinder (7) plays the role of stabilizing and buffering, avoiding the agitation in the tank caused by the impact of the incoming water flow, so that maintaining a stable water flow is conducive to the sedimentation of the tank body sludge; equipped with air compression System (2), suction pipe (5), mud collection tank (6), mud scraper (9), and the sludge collected by the mud scraper (9) is concentrated into the mud collection tank by the suction pipe (5) through rotation In (6), the suction pipe is equipped with an air inlet pipe. When the amount of sludge is light, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com