Self-positioning bottom blanking and forming die for stamped bearing retainer

A technology for bearing cages and forming molds, which is applied in the direction of forming tools, bearing components, shafts and bearings, etc., can solve the problems of not meeting the standard requirements of precision bearing cages, large space occupation, poor molding quality, etc., and achieve saving Effects of manufacturing cost improvement, improvement of molding quality, and improvement of work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

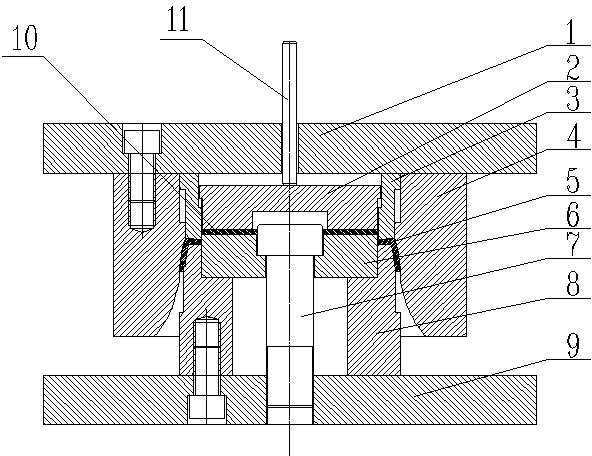

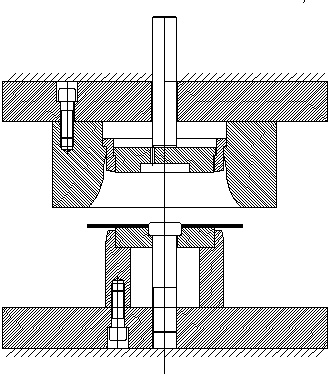

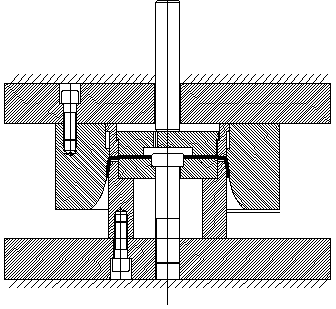

[0023] For in-depth self-positioning and undercut forming precision molds for stamping bearing cages, combined with figure 1 , The description is as follows: Stamping bearing cage self-positioning bottom cutting forming precision mold, including stamping die upper template, stripping body, forming plate, forming die, cage, bottom cutting punch, positioning rod, forming punch, lower template , Bottom-cutting core, punching rod, etc. constitute a precision composite functional mold.

[0024] Structural principles: The stamping bearing cage is self-positioning and bottom-cut forming. The center hole of the upper template of the precision mold passes through the punching rod, and is fixed on the punch of the stamping equipment by bolts. When the plate is working on the inner side of the forming die, it is pressed against the bottom of the bearing cage. The forming die is fixed on the upper die by bolts under the upper die, the forming punch is fixed on the lower die, and the bot...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com