Clamping and straightening mechanism of steel bar straightening device

A technology for clamping mechanism and steel bar, which is applied in the field of clamping and straightening mechanism of steel bar straightening device, which can solve the problems of no steel bar straightening device, etc., and achieve the effects of convenient straightening operation, enhanced clamping force and high degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

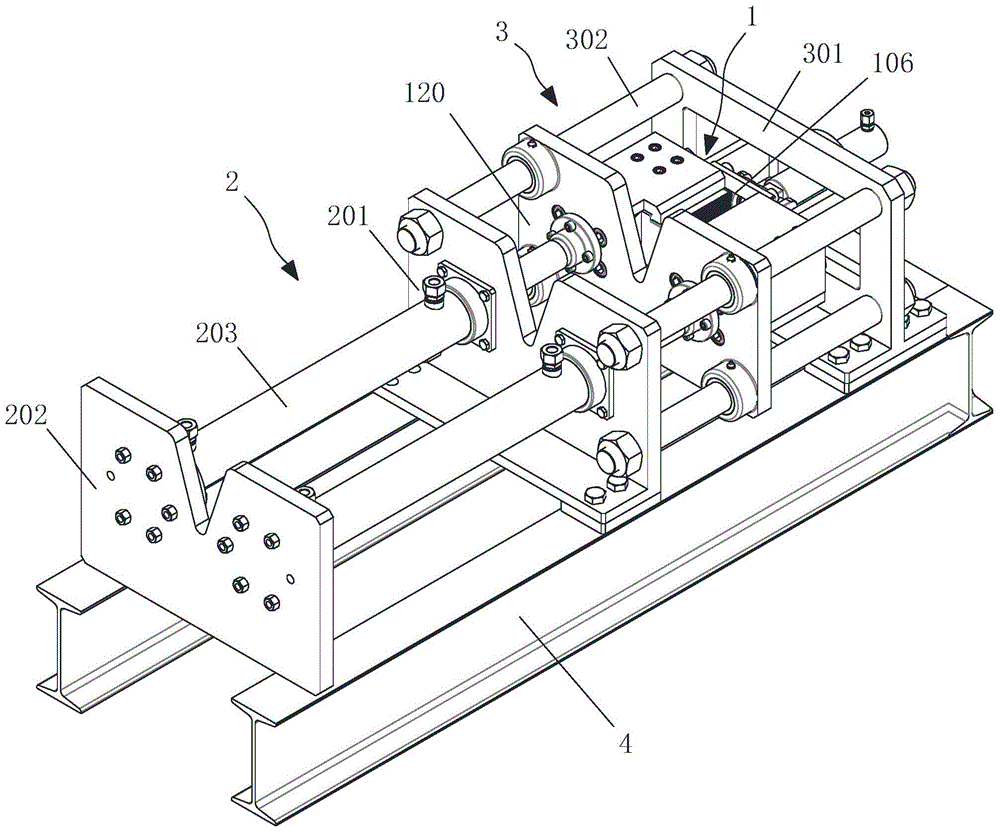

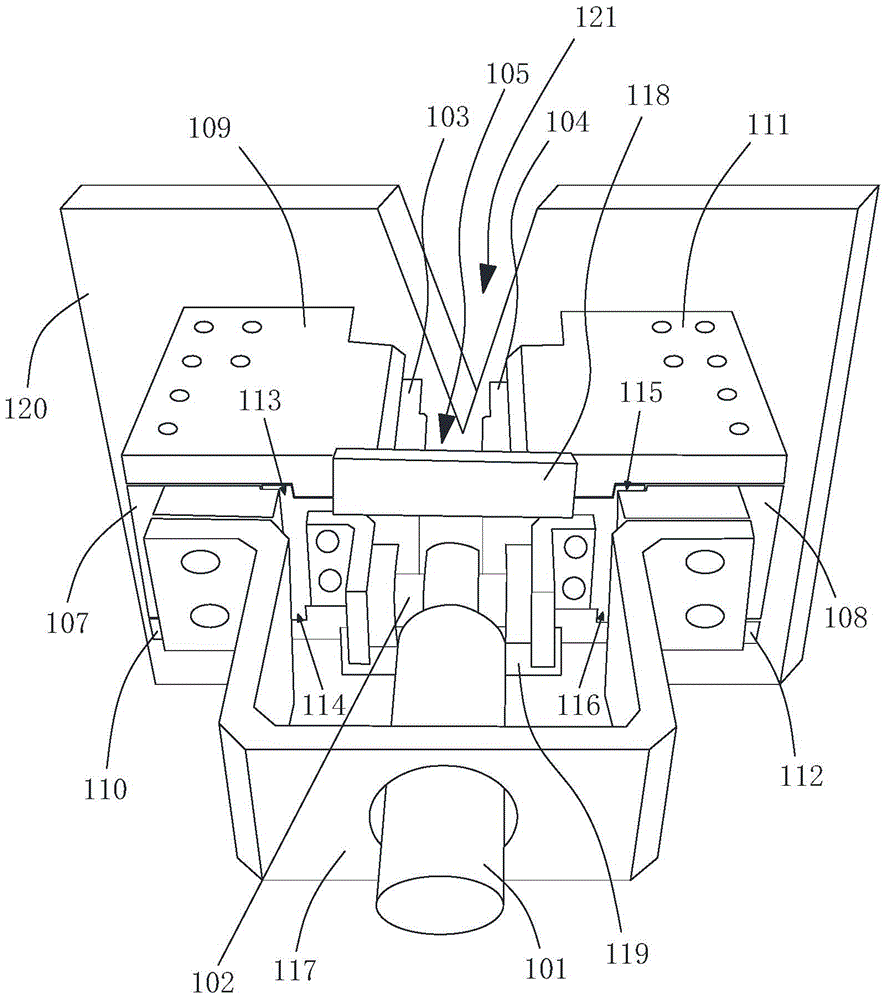

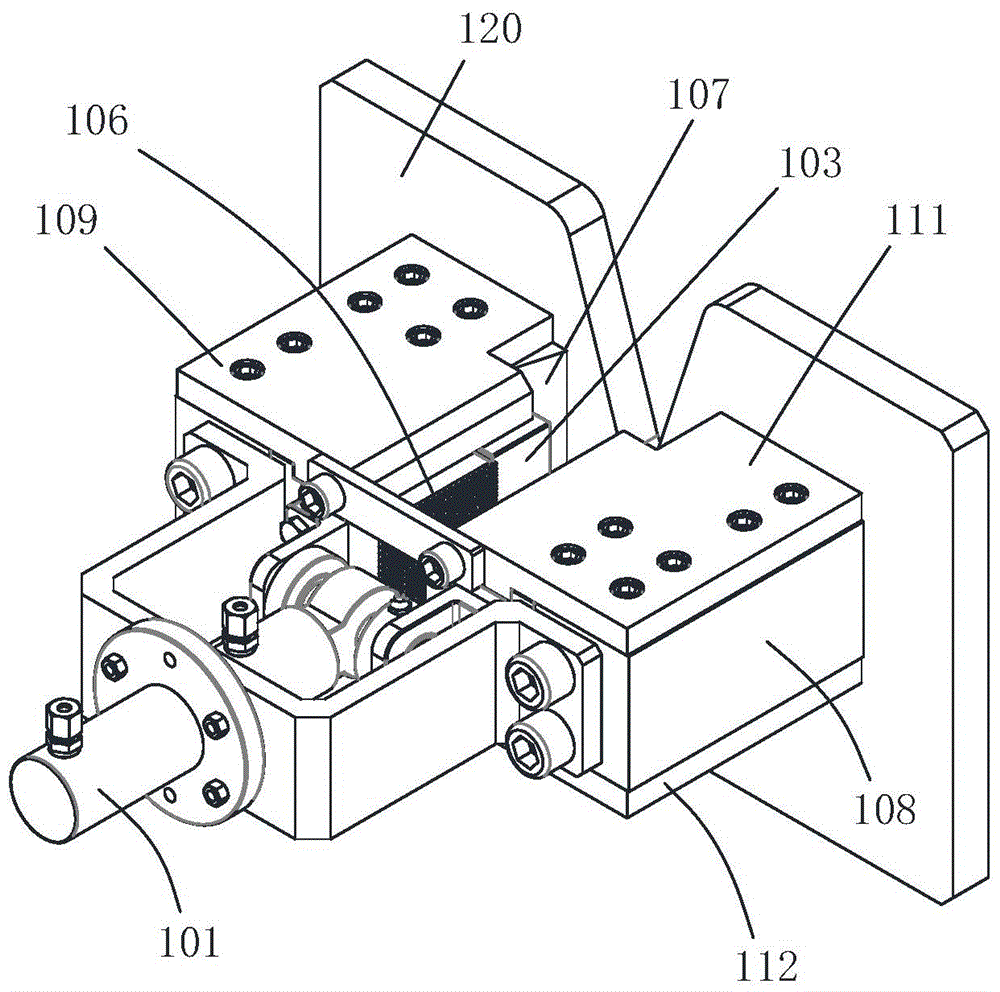

[0020] combine Figures 1 to 3 As shown, the clamping and straightening mechanism of the steel bar straightening device is arranged at one end of the steel bar straightening device, and is used for clamping, fixing and dragging and straightening the steel bar. The steel bar straightening device clamps the straightening mechanism, including a clamping mechanism 1, a straightening mechanism 2 and a guide mechanism 3, and the clamping mechanism is located in front of the straightening mechanism.

[0021] The straightening mechanism 2 comprises a front straightening fixed plate 201 and a rear straightening fixed plate 202, two or four straightening hydraulic cylinders 203 are arranged between the front straightening fixed plate and the rear straightening fixed plate for Drag and straighten the steel bars. One end of the straightening hydraulic cyli...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com