Auxiliary locating tool

An auxiliary positioning and tooling technology, which is applied in positioning devices, guiding/locating/aligning devices, manufacturing tools, etc., can solve the problems of workpiece scrapping, failure to clamp, and side fall, and achieve the effect of preventing side fall

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

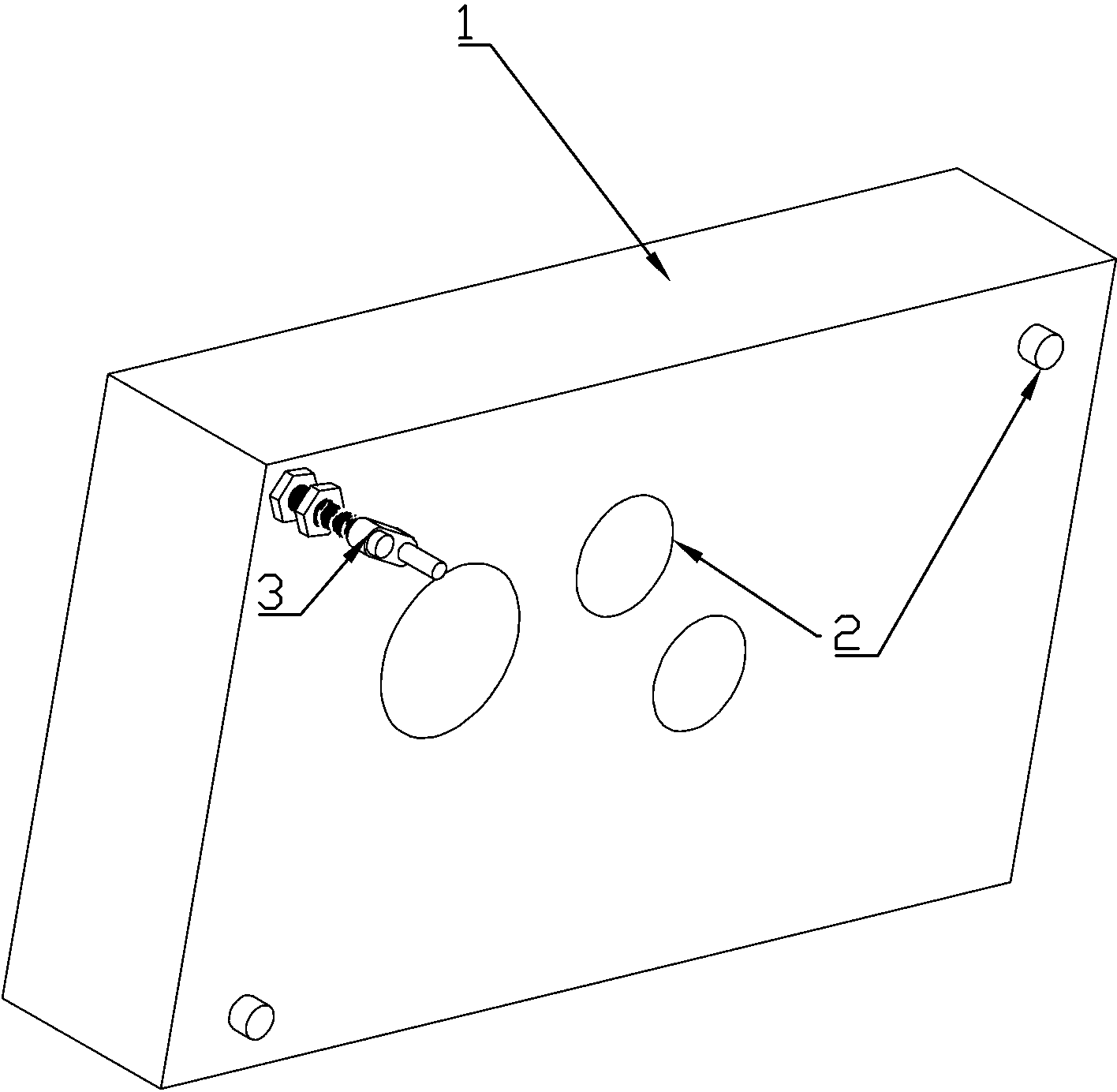

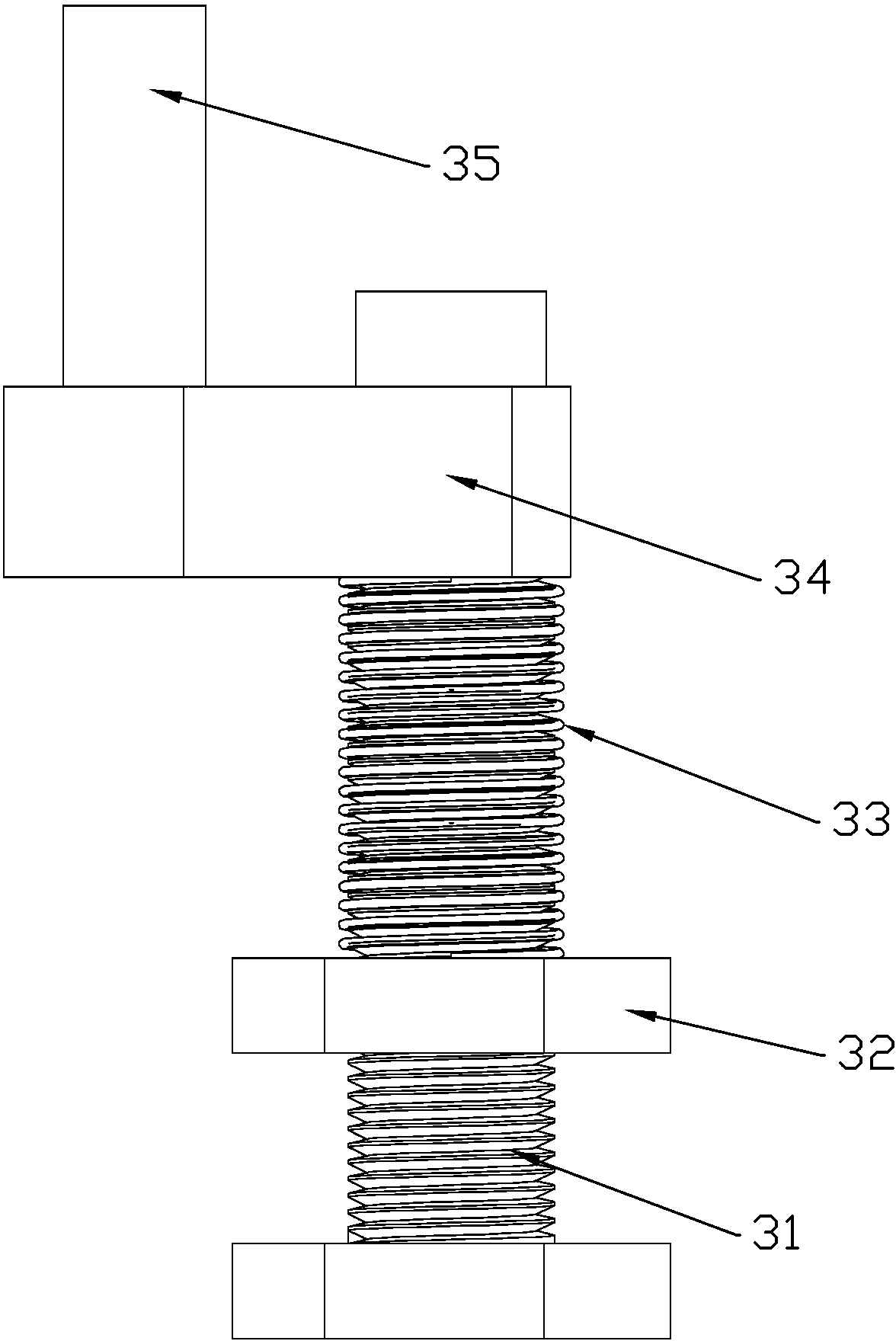

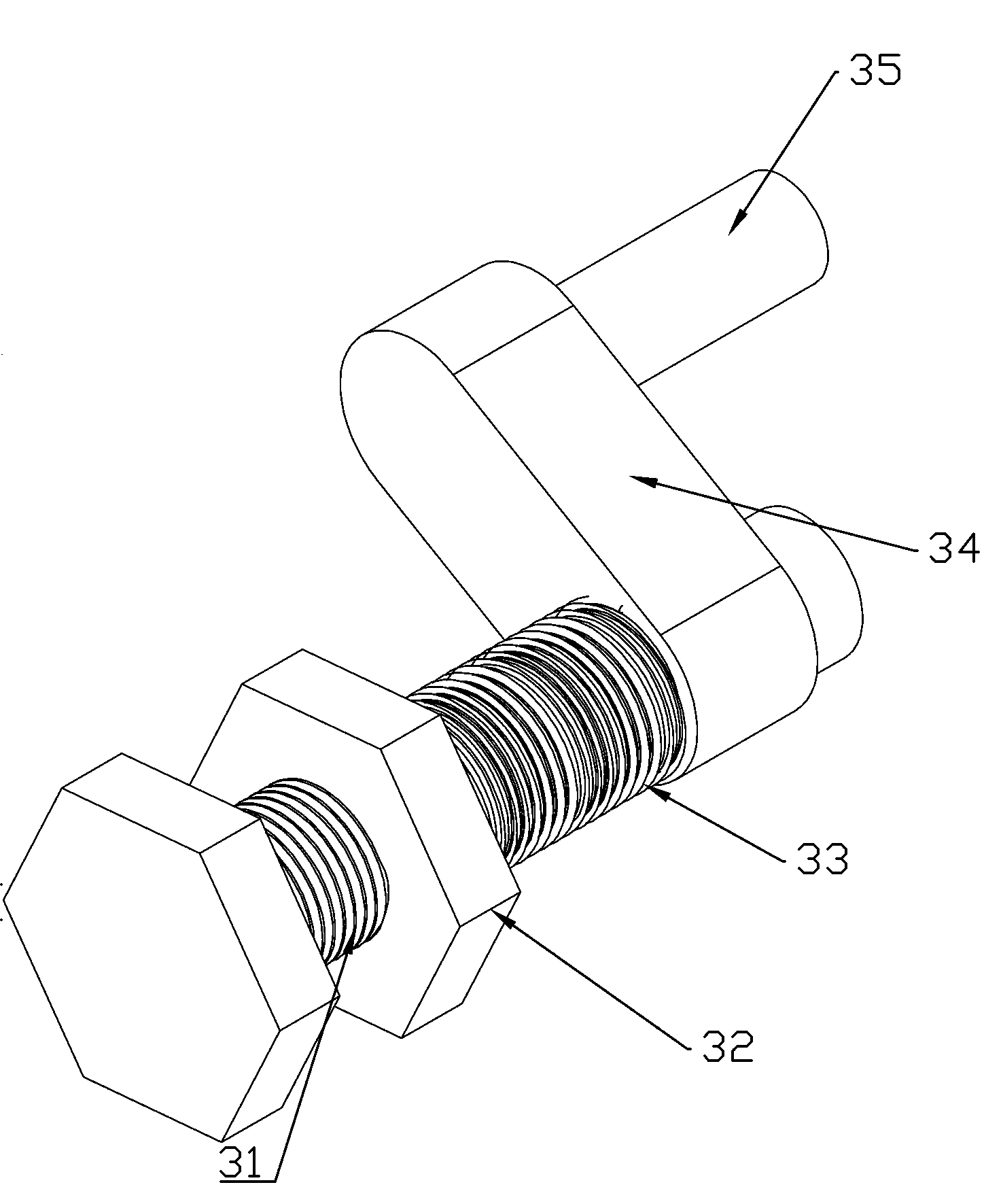

[0013] combined with figure 1 , 2 As shown, the auxiliary positioning tool includes a body, and a vertical workbench 1 is provided on the body, and a horizontal positioning device 2 is provided on the vertical workbench 1, wherein the vertical workbench 1 is provided with a threaded hole, and the threaded hole is connected with a The screw rod 31 is provided with a limiting claw 34, and the limiting claw 34 is hinged on the screw rod 31 with the screw rod 31 as a rotating shaft. The screw rod 31 is covered with a compression spring 33 , the compression spring 33 is located between the vertical worktable 1 and the limiting claw 34 , and the limiting claw 34 is hinged to the screw rod 31 . An adjusting nut 32 is arranged on the screw rod 31 , and the adjusting nut 32 is located between the compression spring 33 and the vertical workbench 1 . A handle 35 is provided on the limiting pawl 34 .

[0014] In use, the horizontal positioning device 2 on the vertical workbench 1 can o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com