Electrical-steam PVC (polyvinyl chloride) plastic board local-heating device

A local heating and plastic board technology, which is applied in the field of local heating devices for electric and steam dual-purpose PVC plastic boards, can solve the problems that the surface of PVC plastic boards is easily scorched, affects the appearance, and cracks, and achieves good heating effect and eliminates scorching , the effect of easy installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

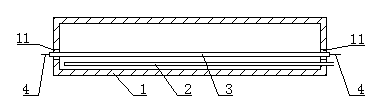

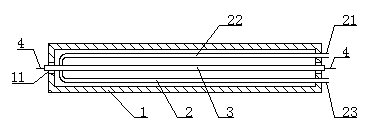

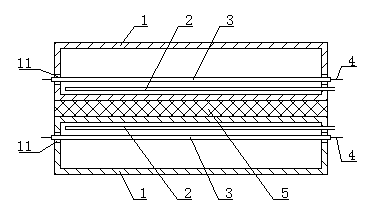

[0009] see Figure 1 to Figure 2 The local heating device for electric and steam dual-purpose PVC plastic plates of the present invention includes a box body 1, an infrared heating tube 3 and a wire 4, and also includes a pipeline 2, and the pipeline 2 includes a steam inlet pipeline 21, a heating pipeline 22 and a steam outlet pipeline 23, Described heating pipeline 22 is contained in the bottom of box body 1 inner cavity, and one end of described heating pipeline 22 is connected steam inlet pipeline 21, and the other end of heating pipeline 22 is then connected steam outlet pipeline 23, and described steam inlet pipeline 21 and steam outlet The pipes 23 are all located outside the box body, and the left and right sides of the box body 1 are symmetrically provided with holes 11, and the left and right ends of the infrared heating tube 3 are respectively installed in the holes on the left side and the right side of the box body 1. 11 and next to the heating pipe 22 above.

[...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com