Low independent suspension of special vehicle chassis

An independent suspension, low-height technology, used in suspension, elastic suspension, vehicle components, etc., can solve problems such as reduced driving safety and handling stability, large wheel runout and wheel angle, and insufficiently compact layout space. , to achieve the effect of improving driving safety, reducing tire wear, improving handling stability and driving safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

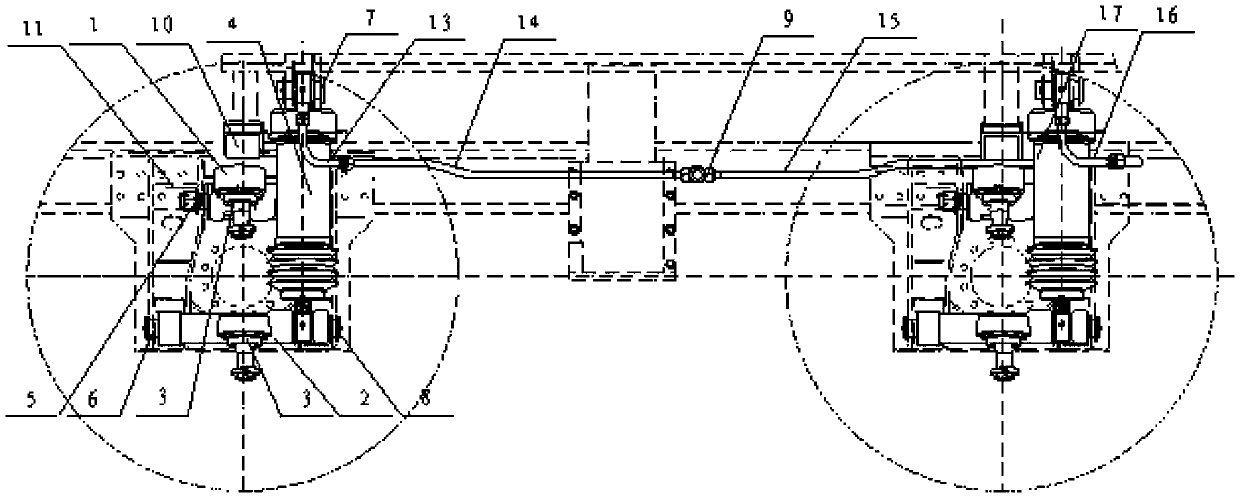

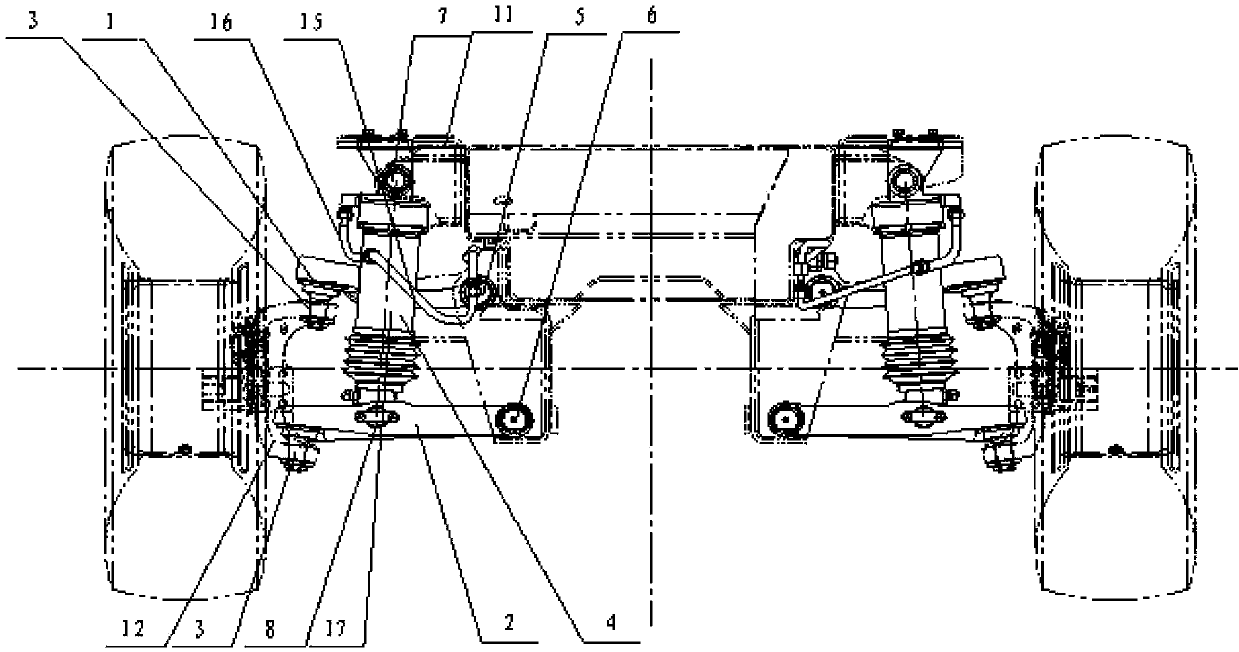

[0026] Such as figure 1 , figure 2 As shown, the low-height independent suspension of the special vehicle chassis of the present invention can connect two or more independent suspension subunits in series through pipelines according to the number of vehicle axles and the use requirements;

[0027] Each independent suspension sub-unit includes upper cross arm 1, lower cross arm 2, ball joint 3, oil-pneumatic spring A4, upper cross-arm pin 5, lower cross-arm pin 6, oil-pneumatic spring upper pin 7, oil-pneumatic spring lower pin 8. Limiting block 10, steering knuckle 12; one end of the upper lug of the oil-gas spring A4 is connected to the frame 11 through the upper pin 7 of the oil-gas spring, and one end of the lower lug of the oil-gas spring A4 is connected to the lower crossbar through the lower pin 8 of the oil-gas spring. The arm 2 is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com