Automobile vacuum booster with mechanical emergency braking auxiliary system function

A vacuum booster and auxiliary system technology, applied in the direction of brakes, brake transmissions, vehicle components, etc., can solve problems such as insufficient pedal force, unresponsive drivers, parking, etc., to achieve high cost, stable performance, assembly easy effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

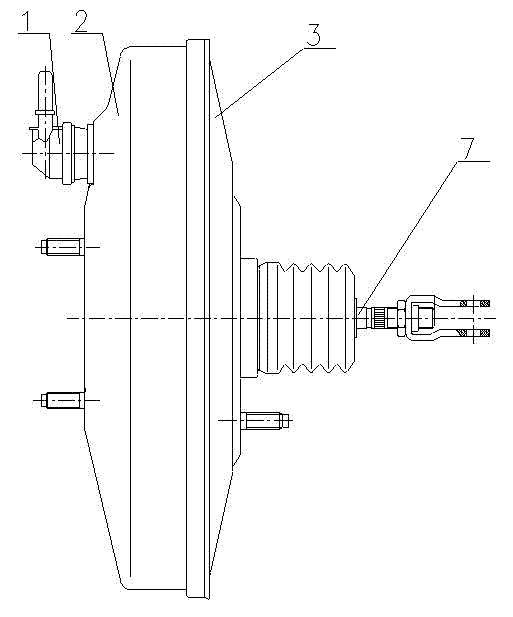

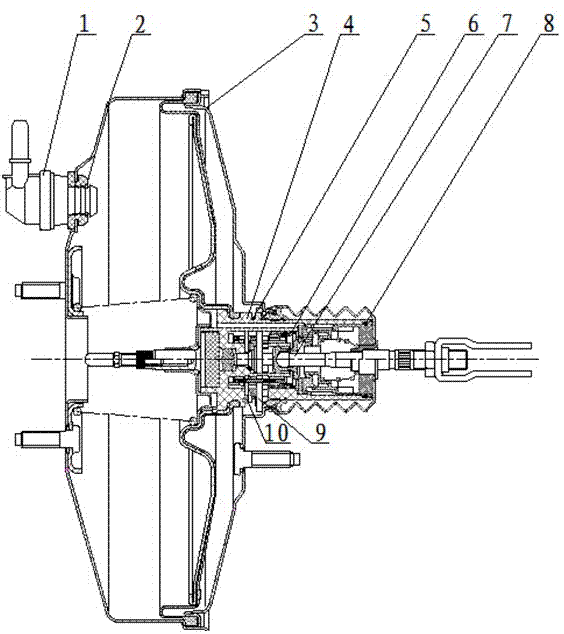

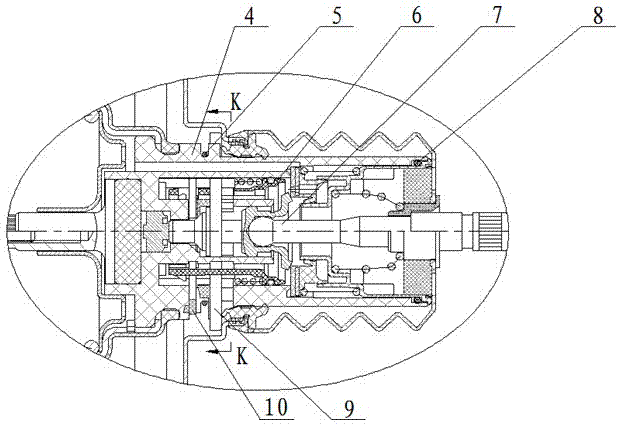

[0030] Such as figure 1 , figure 2 As shown, the present invention includes a front shell 2, a rear shell 3, a piston body 4, a one-way valve assembly 1 and a control valve assembly 7, and the piston body 4 cooperates with the rear shell 3 and moves relative to the piston; the piston body 4 is equipped with Spool valve assembly 6, spool valve retaining piece 10, snap ring 5, locking piece 9 and control valve assembly 7, such as Figure 4 , Figure 5 As shown, the slide valve assembly 6 includes a launch spring 12, an O-ring 13 and a slide valve 11, and the control valve assembly 7 includes a control valve seat 14, a control valve cup 16, a control valve push rod 15, and a push rod return spring 19. The control valve cup pressure spring 17, the control valve spring front seat 18 and the control valve spring rear seat 20, the contro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com