Packaging box structure

A packaging box and double-layer structure technology, applied in the field of packaging box structure, can solve the problems of time-consuming and labor-intensive, easy to produce gaps, loss of wine bottles, etc., and achieve the effect of overall firmness, preventing vibration of wine bottles, and good shockproof function

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

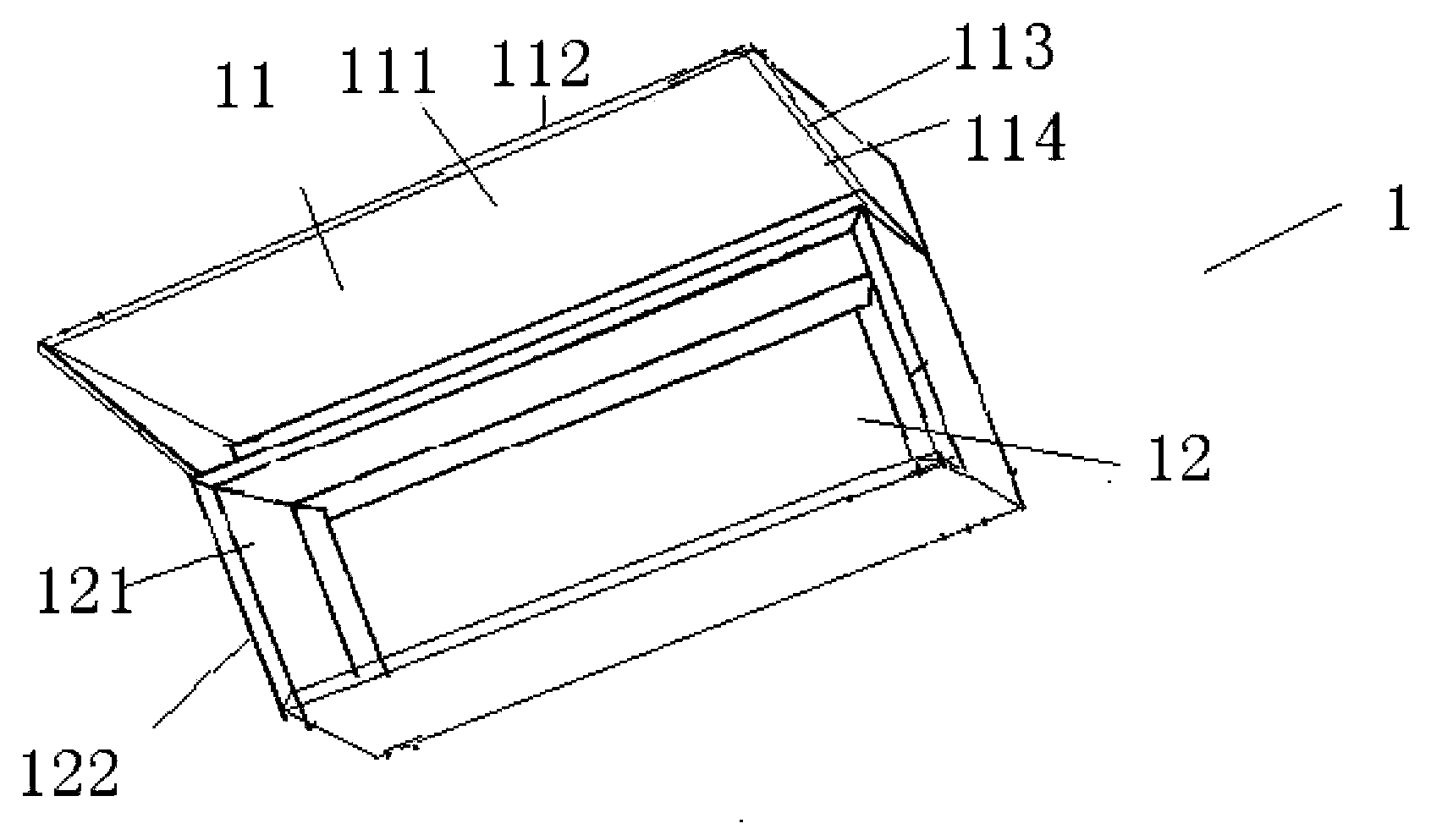

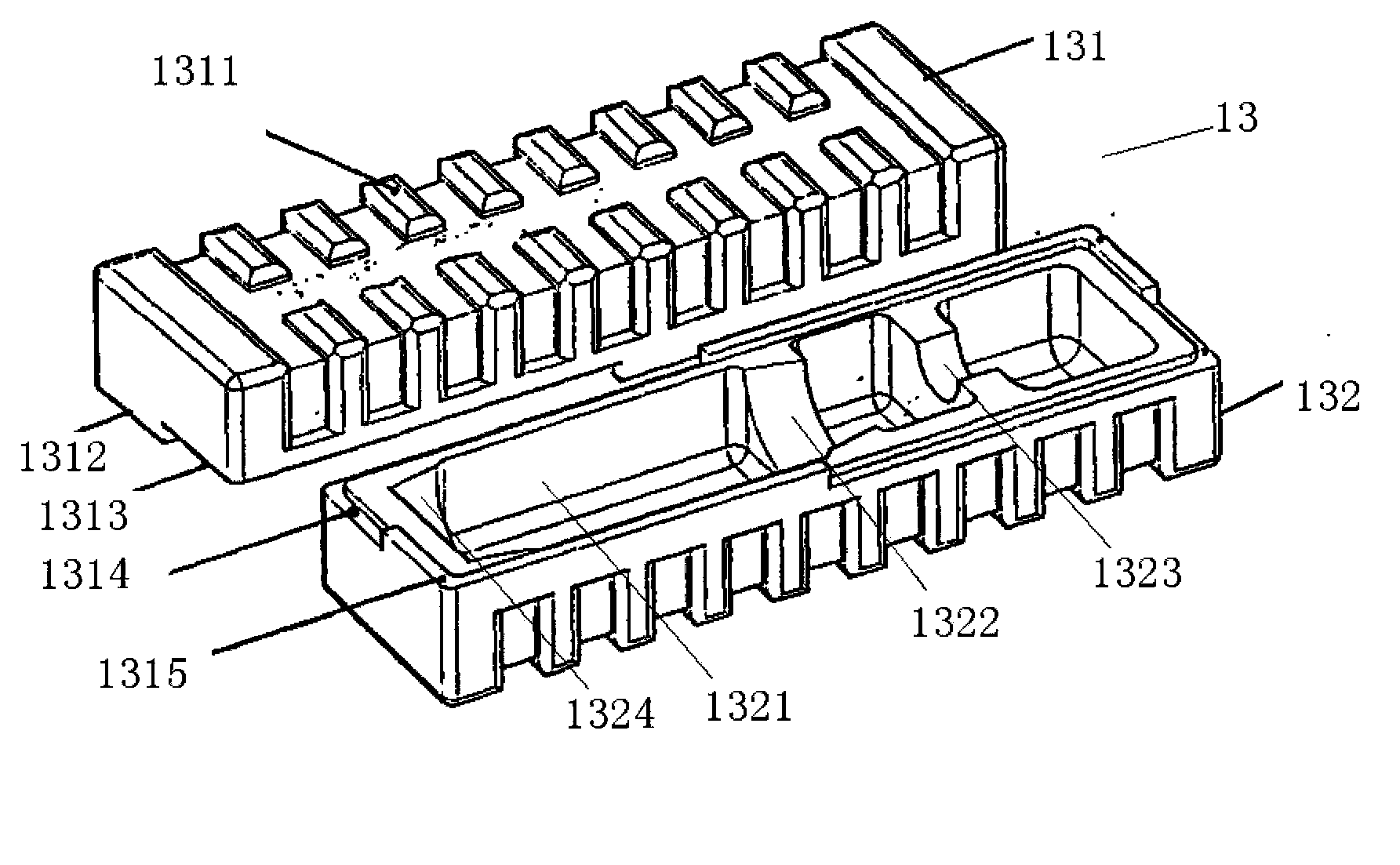

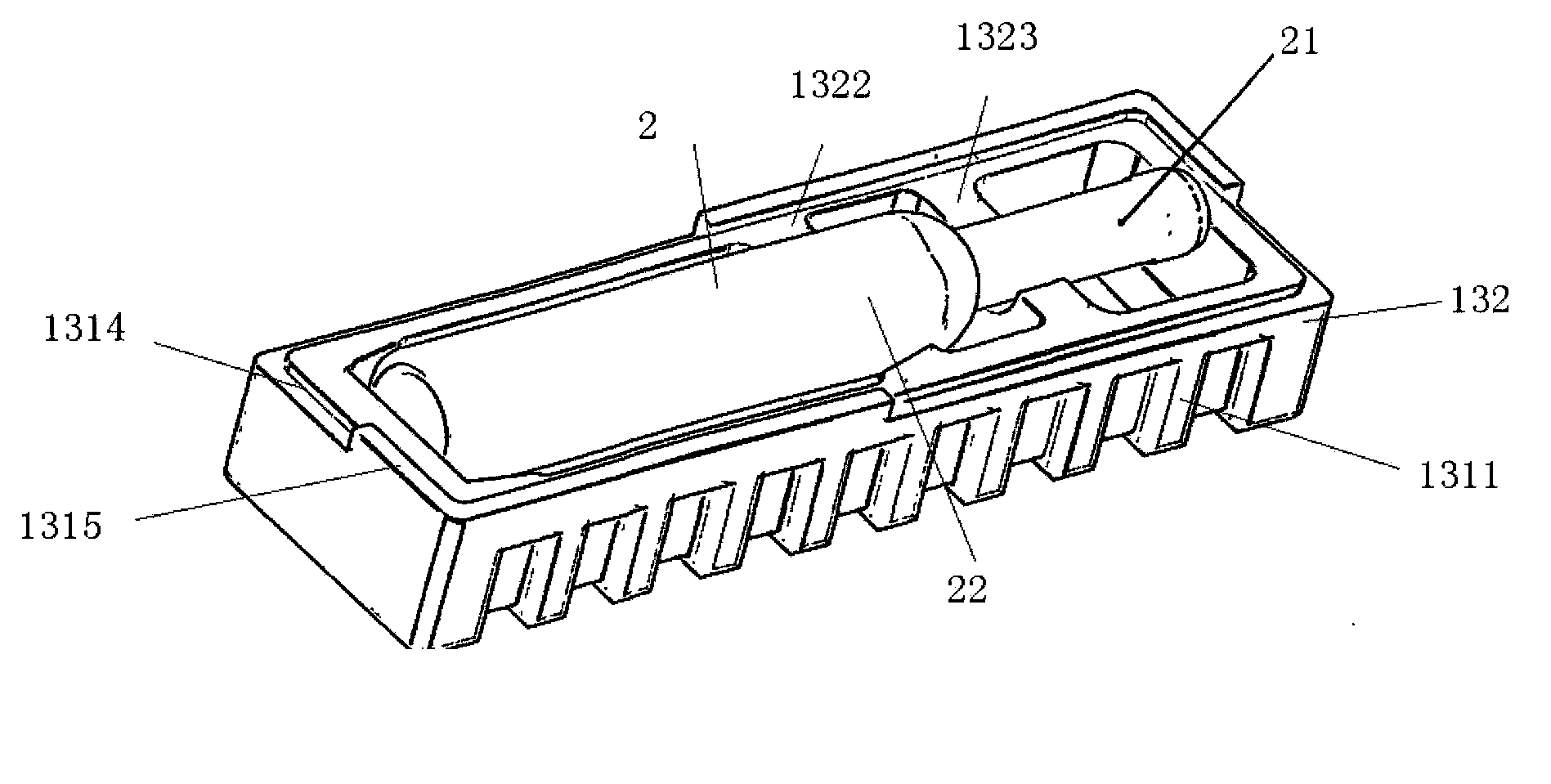

[0015] Please refer to Figure 1 to Figure 3 As shown, the present invention provides a packaging box structure 1, not only the parts constituting the box body are all on the same wrapping paper, the whole is strong and firm, easy to manufacture, and effectively prevents the damage placed in the inner box body during transportation. The wine bottle vibrates and has a good shockproof function.

[0016] Wherein, the packaging box structure 1 mainly includes an outer box body 12, a box cover 11 and an inner box body 13, the box cover 11 is connected to one side edge of the outer box body 12, and the box cover 11 is correspondingly set on the outer box body 12 to form a space for accommodating the inner box body 13 with the outer box body 12 .

[0017] Also, the four sides of the outer box body 12 that are connected to each other in pairs are a double-layer structure composed of an inner side surface 121 and an outer side surface 122. The bottom surface and four sides of the oute...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com