Slow descent pipeline

A pipeline and slow-down technology, applied in the direction of slideway, transportation and packaging, can solve the problems of wear and tear of pipe fittings, and achieve the effect of prolonging service life, slowing wear and reducing impact noise.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

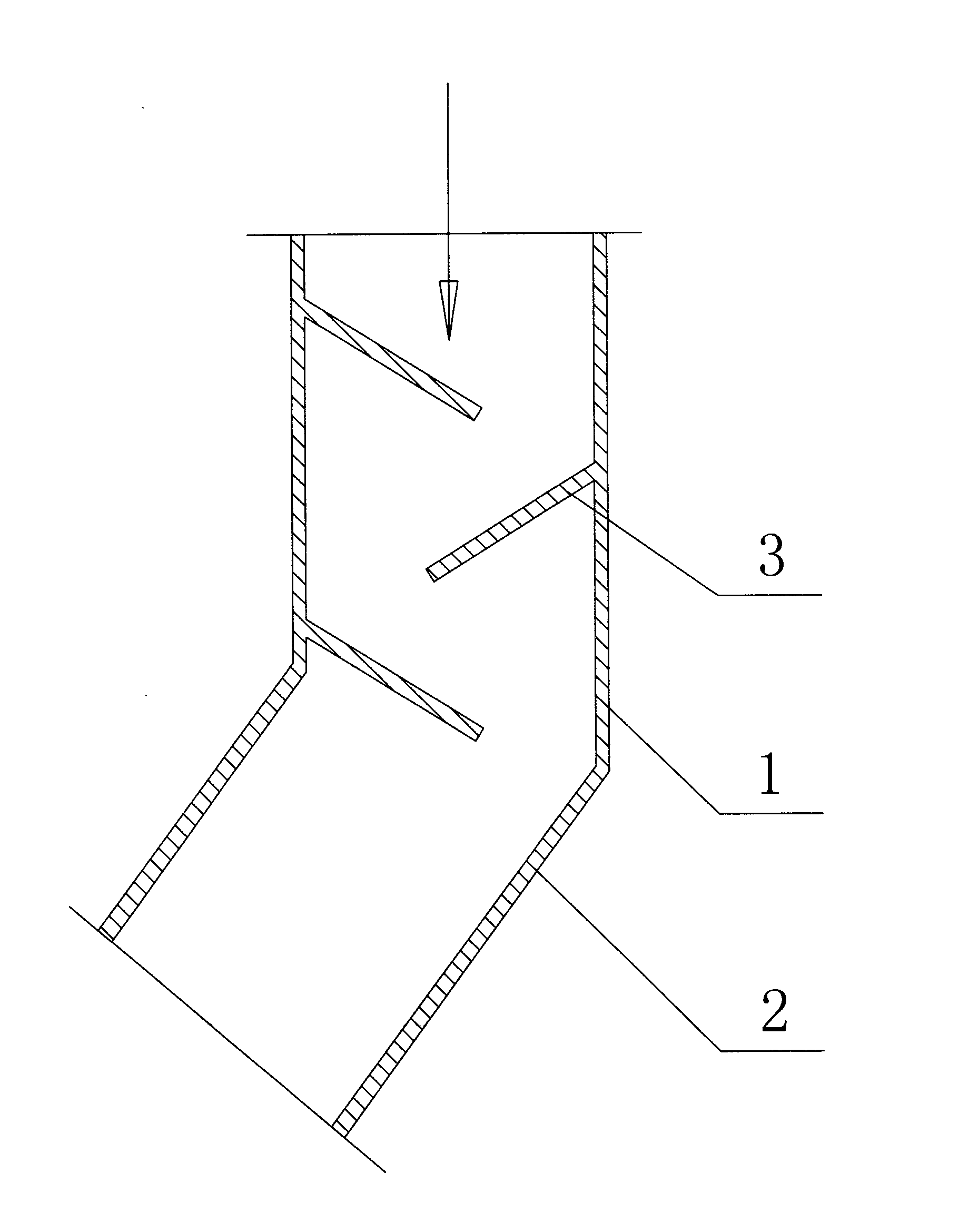

[0010] like figure 1 As shown, a slow-falling pipeline includes an upright section 1 and an inclined section 2. The inclined section 2 is connected to the lower part of the upright section 1. Several inclined baffles 3 are arranged in the upright section 1 along the longitudinal direction. The adjacent inclined baffles 3 are mutually Interspersed, the inclined baffles 3 are provided with at least two layers, and the inclined direction of the lowermost inclined baffle 3 is opposite to that of the inclined section 2 .

[0011] The present invention is not limited to the above-mentioned embodiments. On the basis of the technical solutions disclosed in the present invention, those skilled in the art can make some replacements and modifications to some of the technical features according to the disclosed technical content without creative work. Deformation, these replacements and deformations are all within the protection scope of the present invention.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com