Logistics conveying turning belt conveyor

A technology of belt conveyors and belts, which is applied in the direction of conveyors, conveyor objects, transportation and packaging, etc. It can solve the problems of increasing the difficulty and cost of belt processing, reducing the overall strength of the belt, and affecting the stability of transmission, so as to improve loading and unloading and maintenance. The effect of improving efficiency, improving running stability, and reducing vibration and noise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

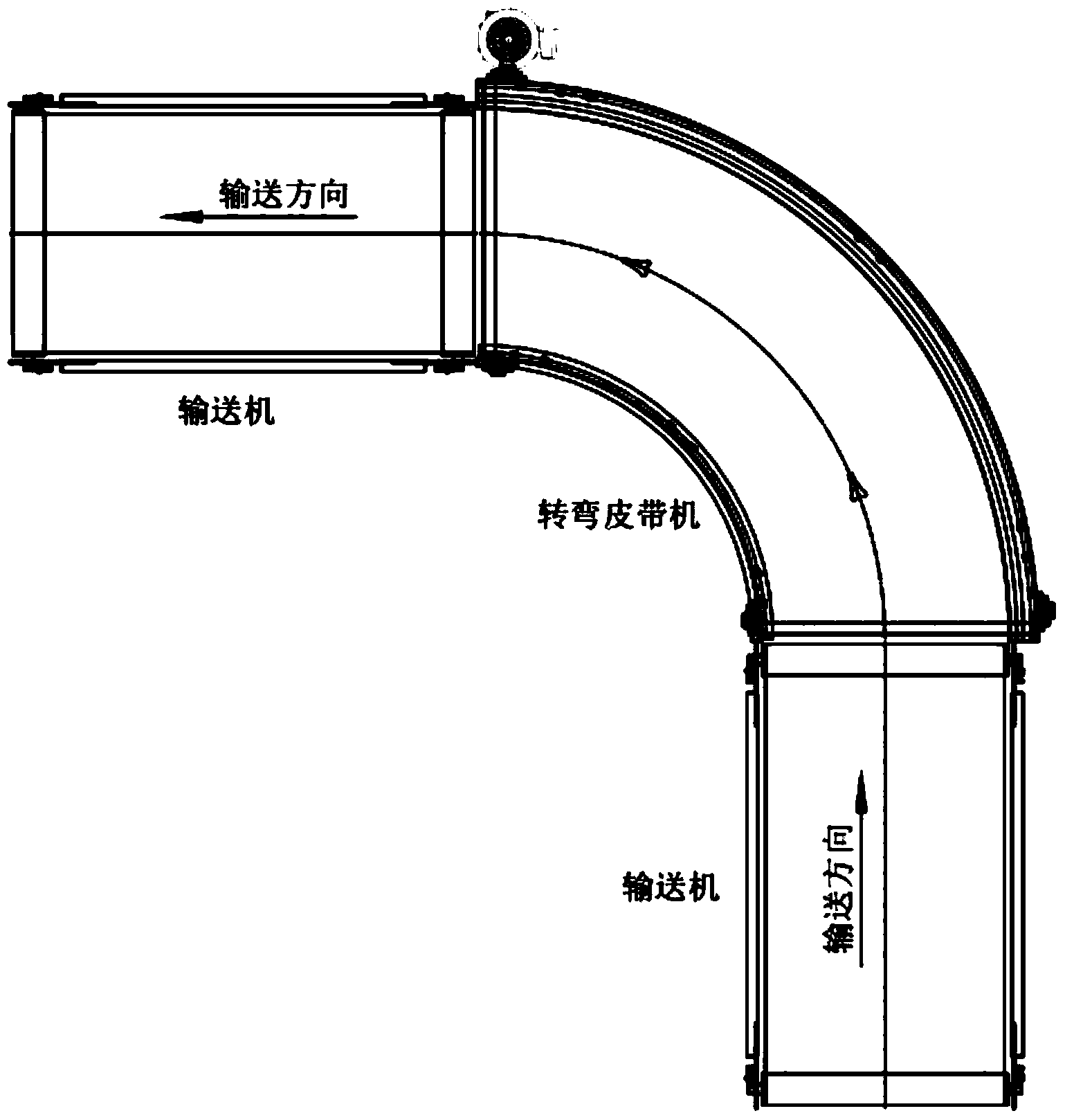

[0041] The patent of the present invention can be preferentially applied to logistics automatic conveying and sorting machinery, especially the turning belt conveyor, which is used to realize the functions of fast loading and unloading and maintenance of the turning belt conveyor, as well as the conveying and steering functions of conveyed items.

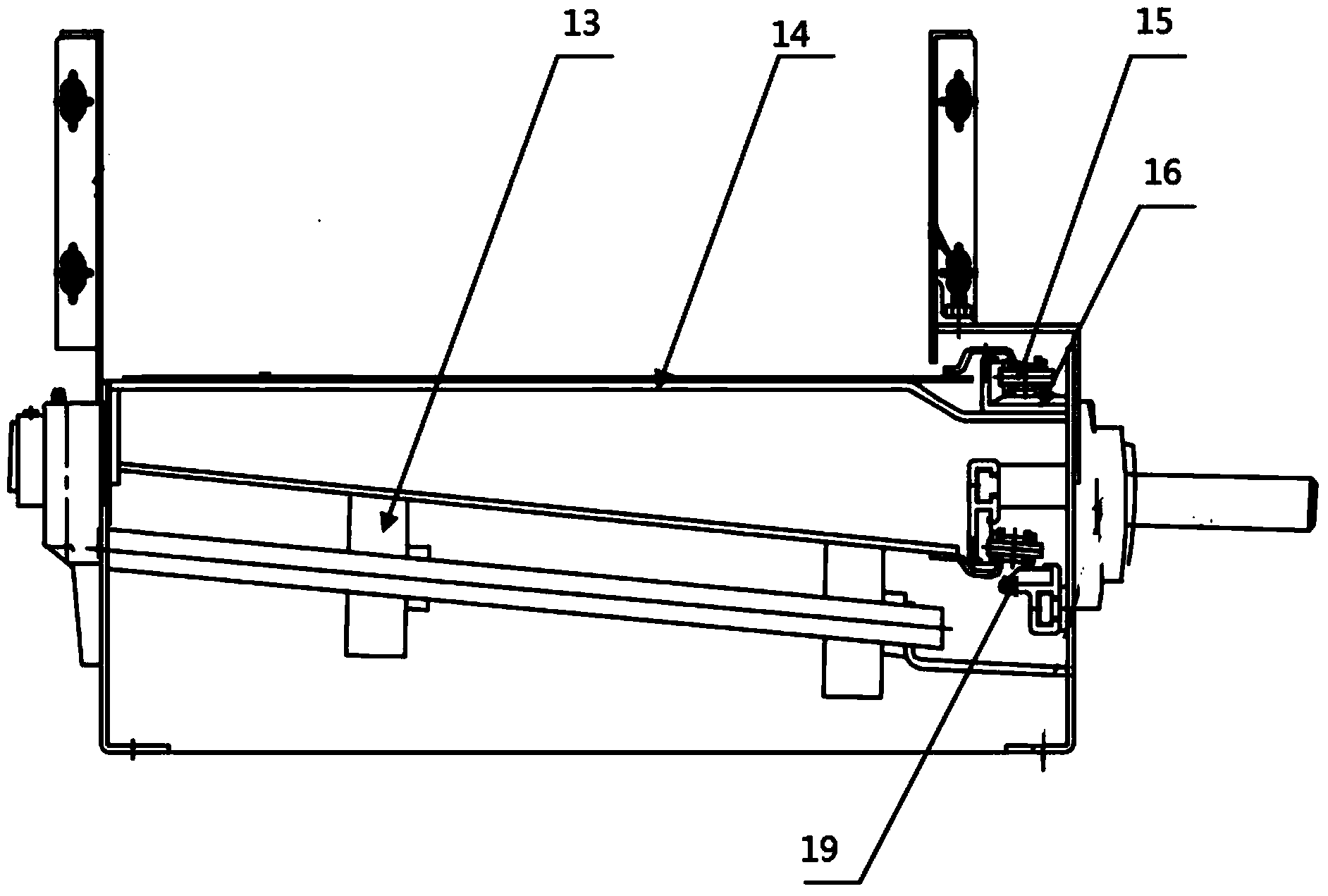

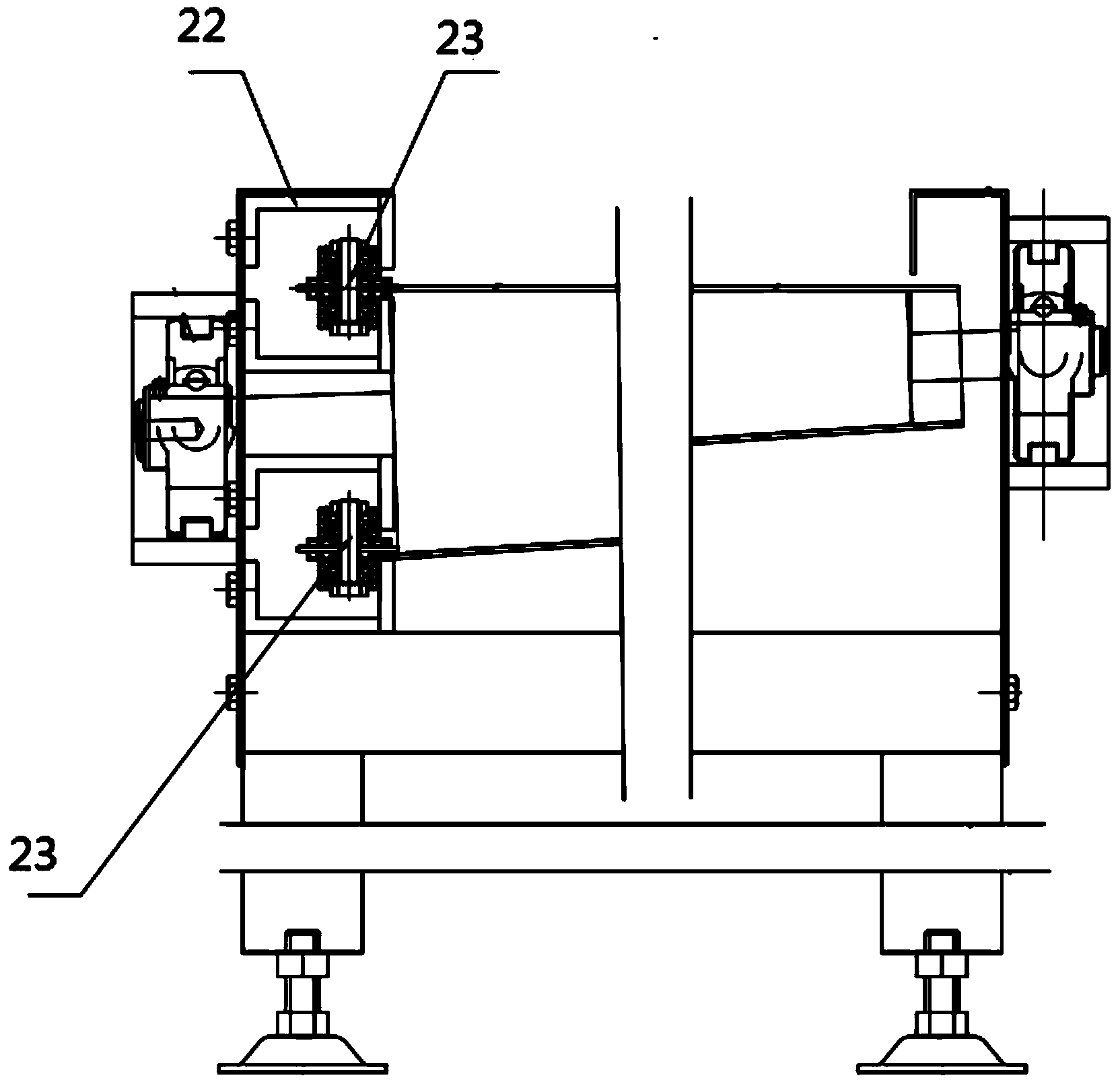

[0042] like Figure 4-6 As shown, the turning belt conveyor is mainly composed of a frame 1, a guide device 3, a turning belt 5, a tapered driving roller 6, a wooden pallet 9, an inner ring guardrail 10, an outer ring guardrail 11, and the like. Multiple groups of guiding devices 3 are evenly fixed on the outer ring frame.

[0043] see Figure 7-9 The bearing rollers 301 of multiple groups of guiding devices 3 play the role of traction and guiding the turning belt, and at the same time, because the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com