A high-speed slitting machine with automatic lifting, tightening and positioning paper core

A high-speed slitting machine and automatic lifting technology, which is applied in the directions of winding strips, thin material processing, transportation and packaging, etc., can solve the problems of not having automatic lifting and deviation correction, not meeting the requirements, not having quasi-cutters and paper cores Kinetic energy and other issues, to achieve the effect of reducing space, reasonable structure, and accurate positioning function

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

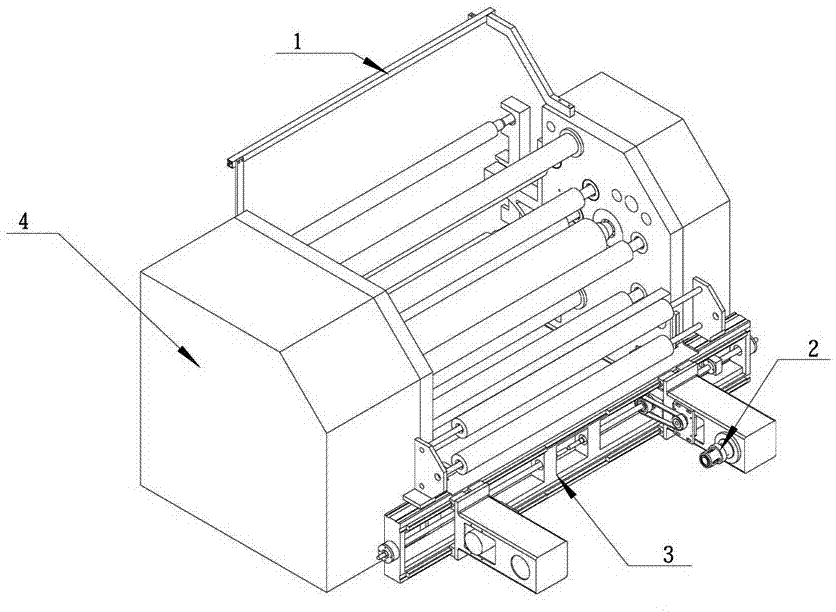

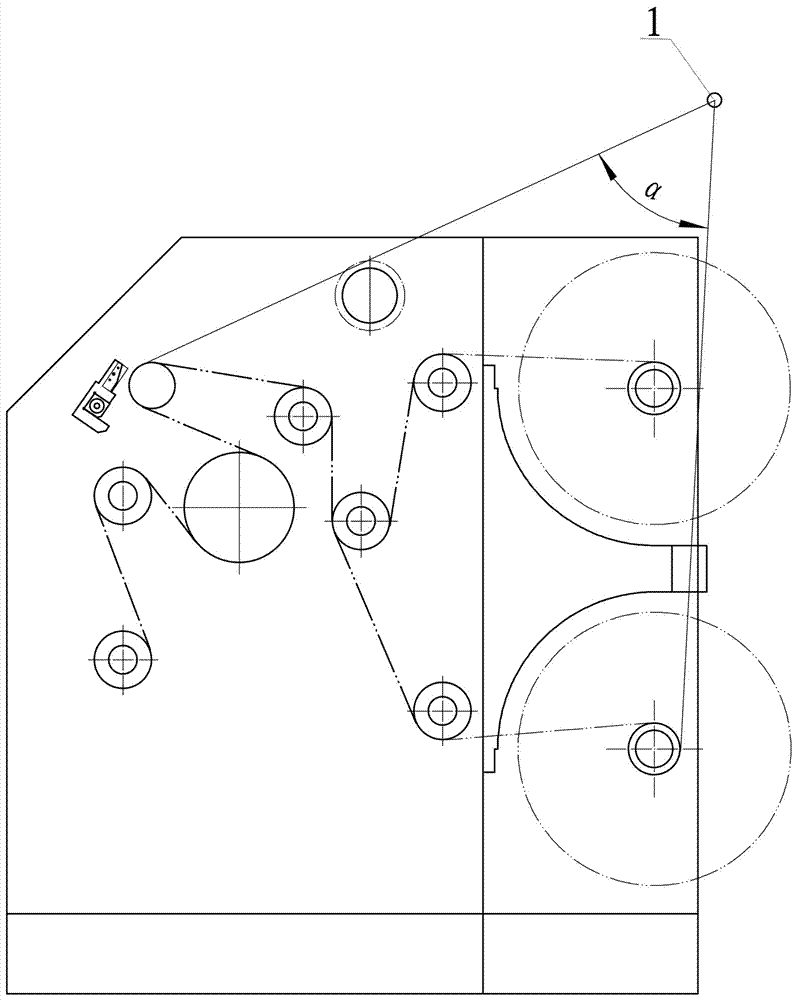

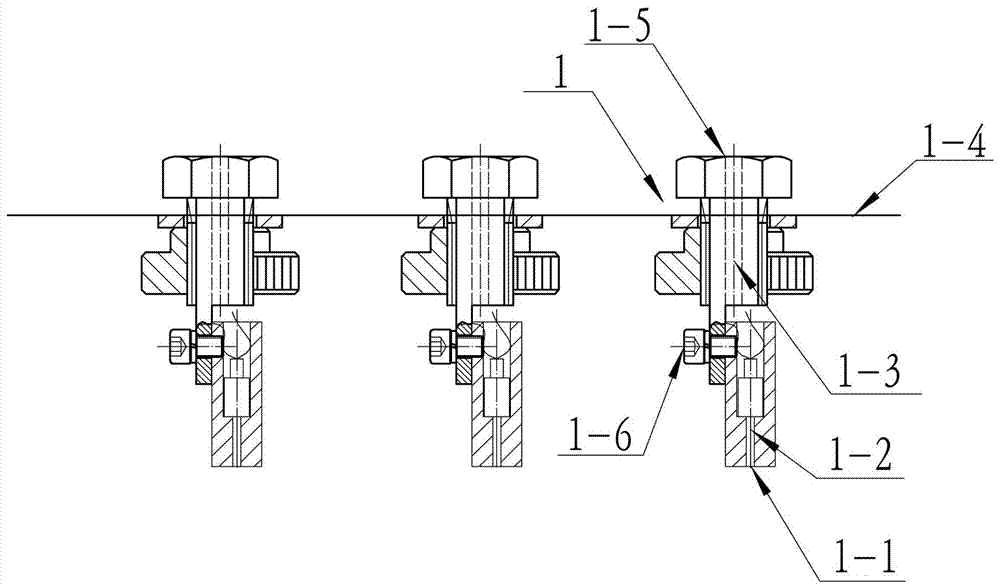

[0021] Such as Figure 1-7 As shown, a high-speed slitting machine with automatic lifting, expansion, tightening and positioning of the paper core is characterized by a mechanism for positioning the paper core (1) of the slitting machine, an automatic expansion and tightening mechanism for retracting and unwinding the roll paper tube (2) and an The automatic lifting and rectifying mechanism (3) for shaft rewinding and unwinding is installed on the frame of the slitter (4), and the mechanism for positioning the paper core (1) of the slitting machine is aligned with the cutter and the roll paper core (2-9) , the automatic expansion and tightening mechanism for rewinding and unwinding the reel (2) expands and locks the reel (2-9), and the shaftless rewinding and rewinding automatic lifting and correcting mechanism (3) for the reel (2-9) ) for automatic lifting and deviation correction.

[0022] The paper core mechanism (1) of the slitting machine is characterized in that the in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com