Cable coiling device of sliding clinometer

A cable winding and inclinometer technology, applied in the field of cable winding devices, can solve problems such as abrasion and signal cable knotting, and achieve the effects of prolonging the service life, reducing cable wear, and being convenient to use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The technical solutions of the present invention will be described in detail below, but the protection scope of the present invention is not limited to the embodiments.

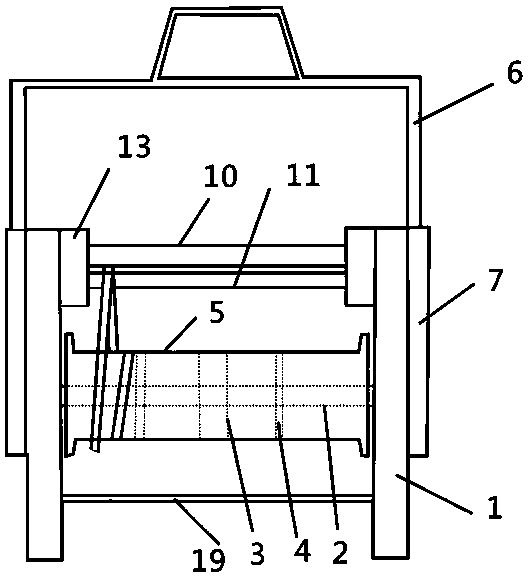

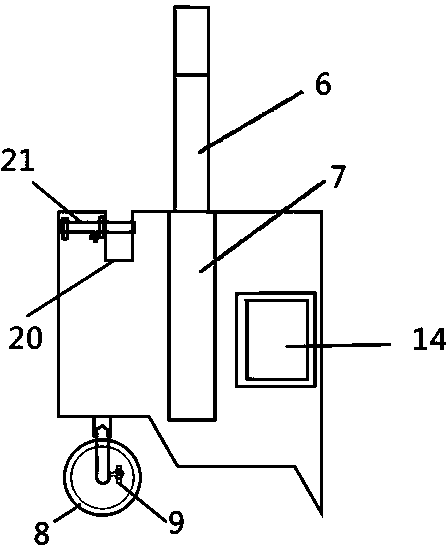

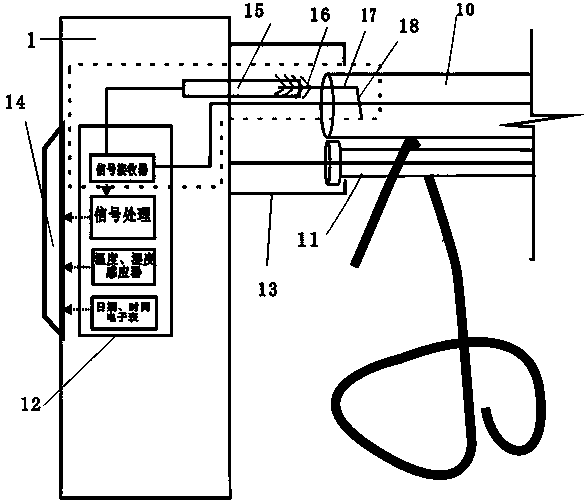

[0017] Such as figure 1 with figure 2 As shown, a cable winding device for a sliding inclinometer is composed of two baffles 1 connected by a connecting shaft 2 and fixed as a whole, and the connecting shaft 2 and the drum 5 are connected by a spring 3 and two bearing 4 connection, the mainspring 3 and the bearing 4 are both sleeved on the connecting shaft 2, and there is a gap of 2 mm between the two ends of the drum 5 and the baffle 1, which can prevent the drum 5 from colliding with the baffle 1 when it rotates. Friction causes energy loss. Two telescopic slots 7 are respectively arranged above the outer sidewalls of the two baffle plates 1 , and corresponding telescopic rods 6 are inserted in the telescopic slots 7 , and the telescopic rods 6 are positioned directly above the connecting shaft 2 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com