Tower body structure for crane

A crane and tower body technology, which is applied in the field of tower body structure of marine hydraulic hose cranes, can solve the problems of inconvenient installation and maintenance of oil pumps, time-consuming and manpower-consuming, immersion, etc. compact effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The specific implementation manner of the present invention will be described below in conjunction with the accompanying drawings.

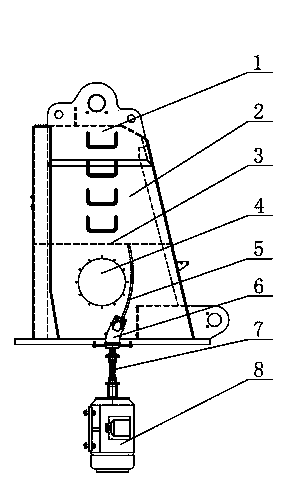

[0014] like figure 1 As shown, the crane tower structure of this embodiment includes a tower body 1, a partition 3 is installed in the middle of the tower body 1, the upper part of the partition 3 is an oil tank 2, and an oil pump is installed at the bottom of the tower body 1 through a fastener. Unit 6, the oil pump unit 6 is connected to the oil tank 2 through the oil suction pipe 5, and the bottom of the oil pump unit 6 is connected to the driving device.

[0015] The bottom of the oil pump unit 6 is connected to the motor 8 through a shaft coupling 7 .

[0016] There is also an observation hole 4 on the tower body 1, and the opening position of the observation hole 4 is located at the lower part of the dividing plate 3. The design of the observation hole 4 is convenient for workers to observe the working conditions in the tower body ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com