Novel lock of supporting arm of lifter

A lift and arm lock technology, applied in the field of arm locks, can solve problems such as inconvenient welding and installation, forgotten manual operation, troublesome operation, etc., and achieve the effects of avoiding falling, convenient use, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

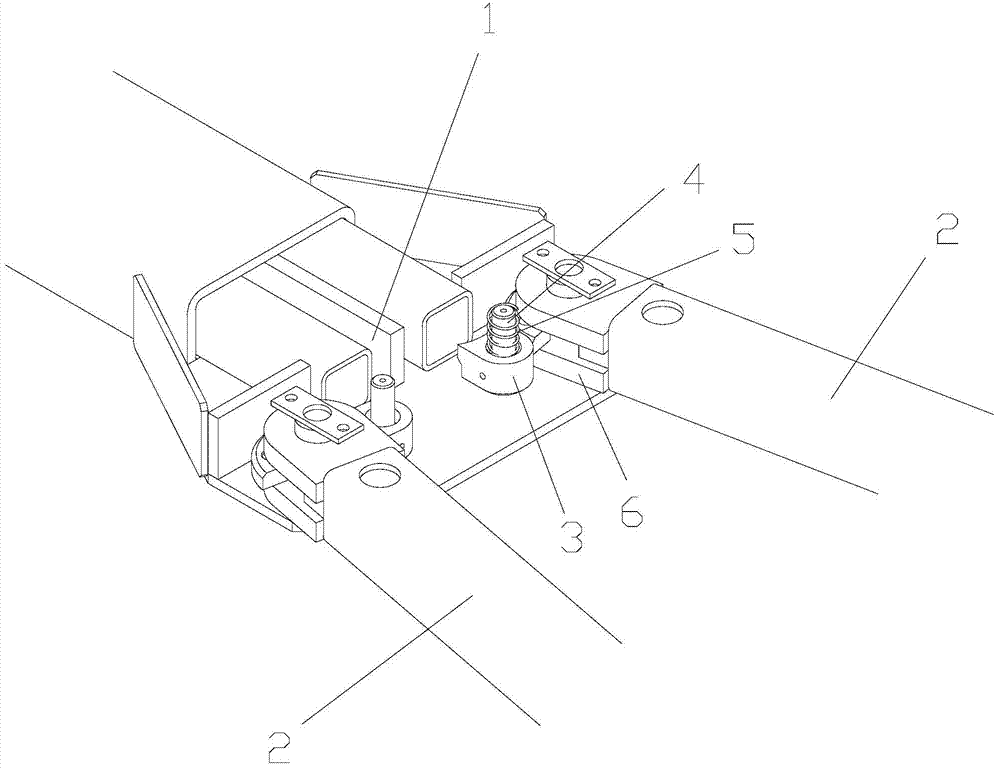

[0008] This new lift arm lock, such as figure 1 As shown, it is installed in the lifting base 1 of the lift, and one end of the support arm 2 is pivotally connected in the lifting base 1 .

[0009] The arm lock includes a tooth block 3 provided with meshing teeth. The upper surface of the tooth block 3 is provided with a guiding connecting shaft 4, and the lower surface is provided with a grounding connecting shaft. The guiding connecting shaft 4 and the grounding connecting shaft are respectively installed on the top plate and the bottom plate of the lifting base 1. In the shaft hole provided, a return spring 5 is installed on the guide connecting shaft 4, and one end of the return spring 5 is against the upper surface of the gear block 3, and the other end is against the lifting base 1 top plate, and the grounding connecting shaft stretches out the lifting base 1.

[0010] The tooth block 3 can move up and down in the lifting base 1 , and the inner end of the support arm 2 i...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap