Forged piece waste heat quenching machining tool

A technology of waste heat quenching and forging parts, applied in the field of quenching machine tools, can solve problems such as high power consumption, and achieve the effect of improving production efficiency and control accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

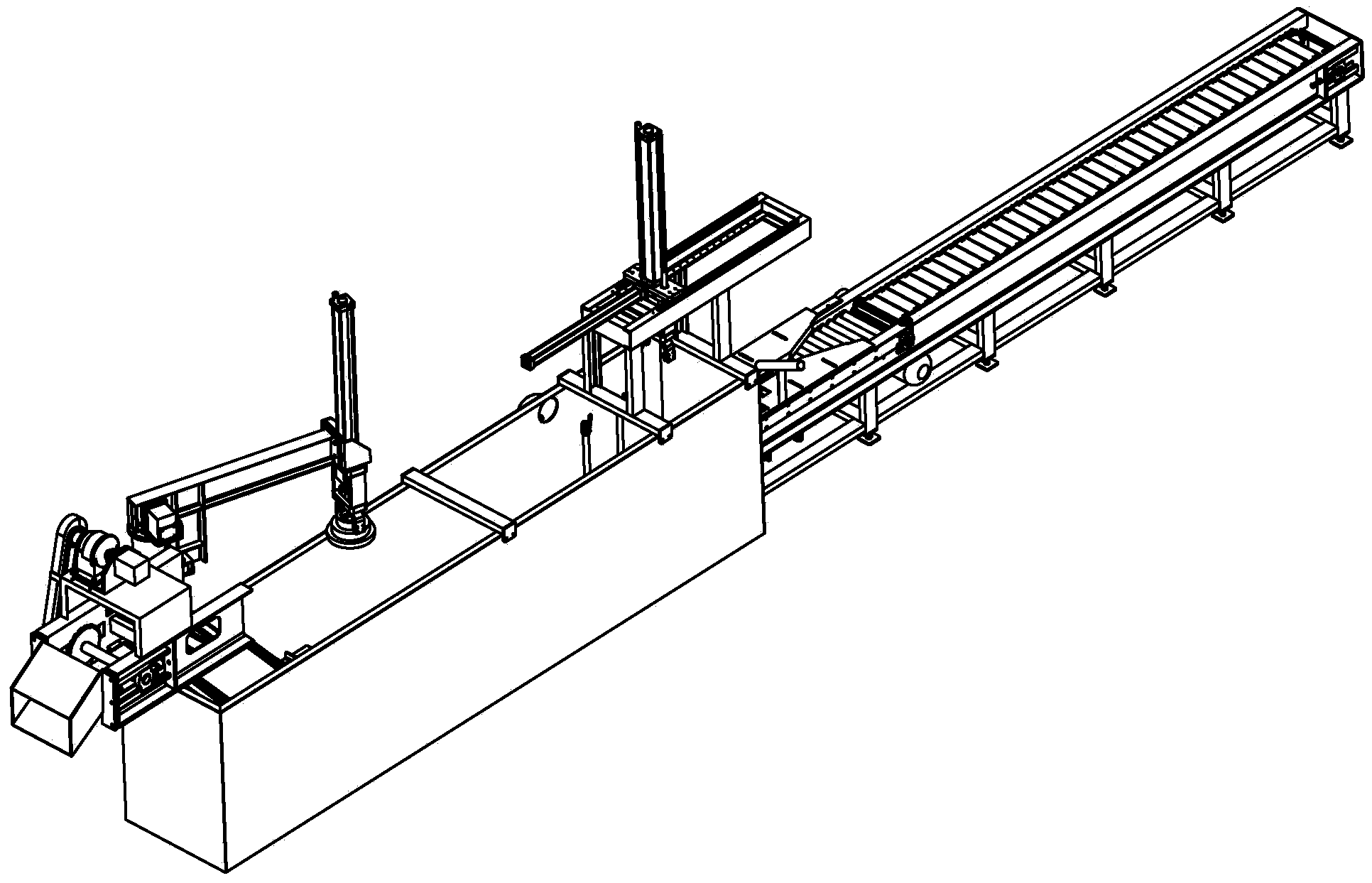

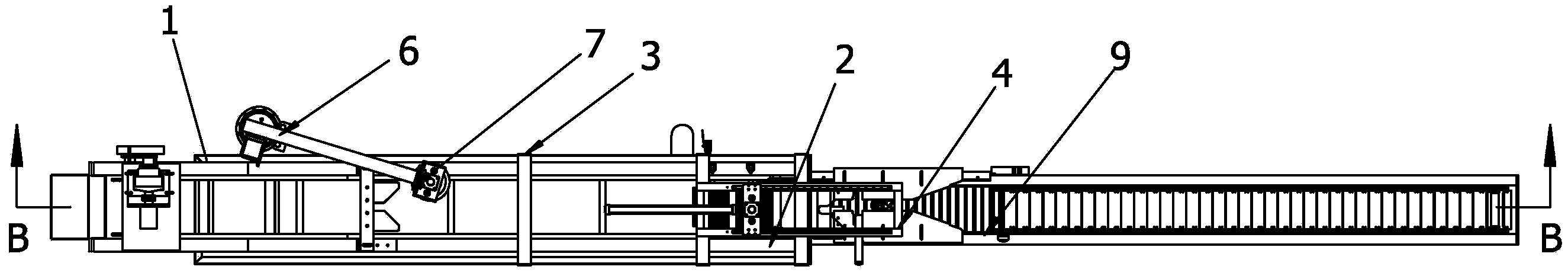

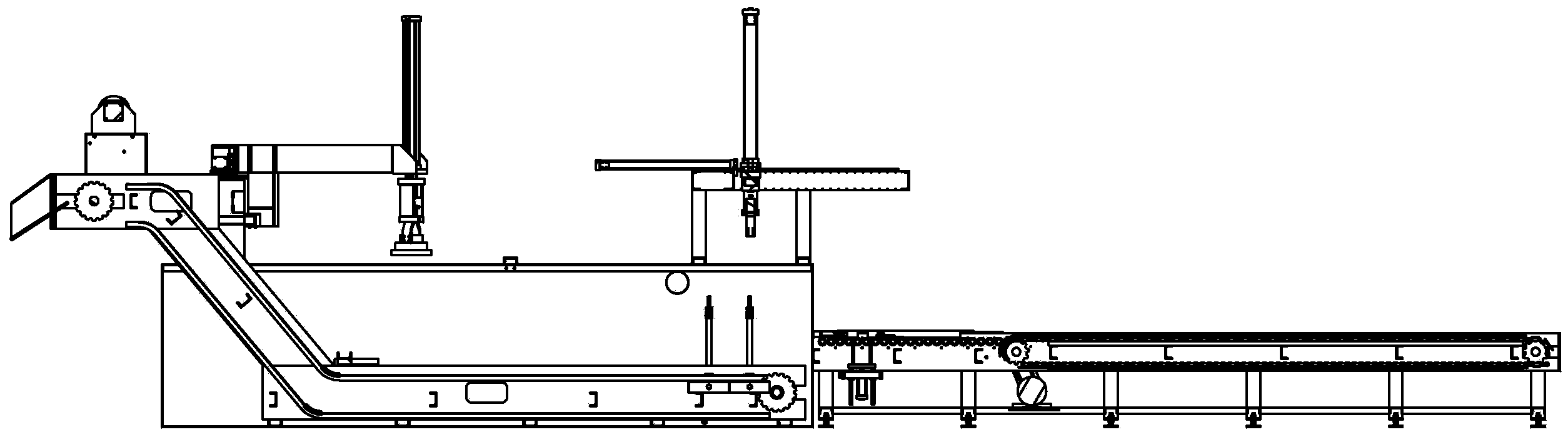

[0015] Such as Figure 1-3 As shown, the waste heat quenching machine tool for forgings of the present invention includes a forging input unit 9 composed of track shoes combined with chains and sprockets. A temperature probe 10 is arranged at the end of the input unit 9; The transfer unit holds the starting end of the forging, and the manipulator transfer unit transports the forging to the quenching tank at the end; the quenching tank is filled with quenching liquid; the quenching tank is also equipped with a Output unit for sending out forged parts.

[0016] In the figure, the number 1 is a water tank, which is used as a quenching tank; the number 2 is a lifting device, which is a part of the transfer unit of the manipulator; the number 3 is the reinforcement structure of the equipment support; the number 4 is a clamping manipulator, which is a part of the transfer unit of the manipulator; Number 6 is a rotating manipulator, which is a part of the transfer unit of the manipu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com