A kind of fabric formaldehyde-free color-fixing agent and preparation method thereof

An aldehyde-free color-fixing agent and fabric technology, which is applied in dyeing, textile and paper making, etc., can solve the problems of mutual staining of fabrics, easy fading, and old fabrics, etc., and achieve the effects of improving washing fastness and simple preparation process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

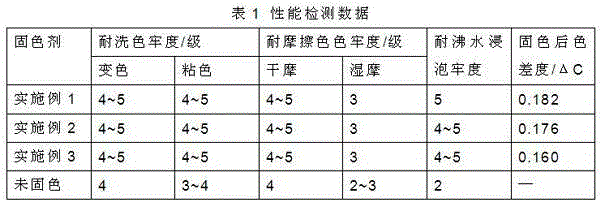

Examples

Embodiment 1

[0014] A fabric formaldehyde-free color-fixing agent, comprising the following components in parts by weight: 15 parts of n-butyl acrylate, 5 parts of chitosan quaternary ammonium salt, 6 parts of isobornyl methacrylate, acryloyloxyethyl 7 parts of trimethylammonium chloride, 8 parts of triallylamine, 2 parts of vinyl siloxane, 3 parts of glacial acetic acid, 0.1 part of azobisisobutylcyanide, and 100 parts of deionized water.

[0015] The preparation method of the present embodiment fabric formaldehyde-free color-fixing agent comprises the steps:

[0016] (1) Dissolve acryloyloxyethyltrimethylammonium chloride and triallylamine in some deionized water, then add azobisisobutylcyanide, and react at 40°C for 1 hour to obtain a reaction solution;

[0017] (2) Continue to add n-butyl acrylate, chitosan quaternary ammonium salt, isobornyl methacrylate, vinyl siloxane and the remaining deionized water to the reaction solution obtained in step (1), keeping the temperature at Keep at...

Embodiment 2

[0019] A fabric formaldehyde-free color-fixing agent, comprising the following components in parts by weight: 25 parts of n-butyl acrylate, 9 parts of chitosan quaternary ammonium salt, 10 parts of isobornyl methacrylate, acryloyloxyethyl 14 parts of trimethylammonium chloride, 10 parts of triallylamine, 5 parts of vinyl siloxane, 5 parts of glacial acetic acid, 1 part of azobisisobutylcyanide, and 120 parts of deionized water.

[0020] The preparation method of the present embodiment fabric formaldehyde-free color-fixing agent comprises the steps:

[0021] (1) Dissolve acryloyloxyethyltrimethylammonium chloride and triallylamine in some deionized water, then add azobisisobutylcyanide, and react at 60°C for 2 hours to obtain a reaction solution;

[0022] (2) Continue to add n-butyl acrylate, chitosan quaternary ammonium salt, isobornyl methacrylate, vinyl siloxane and the remaining deionized water to the reaction solution obtained in step (1), keeping the temperature at Keep ...

Embodiment 3

[0024] A fabric formaldehyde-free color-fixing agent, comprising the following components in parts by weight: 20 parts of n-butyl acrylate, 7 parts of chitosan quaternary ammonium salt, 8 parts of isobornyl methacrylate, acryloyloxyethyl 12 parts of trimethylammonium chloride, 9 parts of triallylamine, 4 parts of vinyl siloxane, 4 parts of glacial acetic acid, 0.5 parts of azobisisobutylcyanide, and 110 parts of deionized water.

[0025] The preparation method of the present embodiment fabric formaldehyde-free color-fixing agent comprises the steps:

[0026] (1) Dissolve acryloyloxyethyltrimethylammonium chloride and triallylamine in some deionized water, then add azobisisobutylcyanide, and react at 50°C for 1.5h to obtain a reaction solution;

[0027] (2) Continue to add n-butyl acrylate, chitosan quaternary ammonium salt, isobornyl methacrylate, vinyl siloxane and the remaining deionized water to the reaction solution obtained in step (1), keeping the temperature at At 45°C...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com