Concrete joint water stop structure and construction method thereof

A concrete structure and concrete technology, which is applied in water conservancy projects, sea area projects, construction, etc., can solve problems such as difficult replacement, affecting water-stop effect, and difficult vibration of concrete, so as to achieve the effect of convenient construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

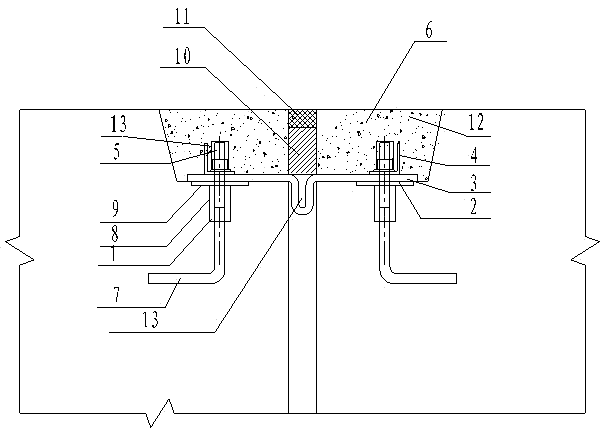

[0026] The technical scheme of the present invention is described in detail below in conjunction with accompanying drawing:

[0027] In projects like the Shahe U-shaped aqueduct, the water-stop structure is very important to the aqueduct body. If water leaks during the normal water delivery period, it will not only affect the overall project appearance, but also may freeze in winter. . The Shahe U-shaped aqueduct was originally designed as a pressure plate water stop, and there is a putty material under the water stop. The water stop is pressed to the concrete surface with bolts to achieve the water stop effect. When the water-stop test was carried out in the later stage, the effect was not ideal, and there were more or less water leakage or water seepage at the water-stop joints. After several water-stop tests, it was found that the reasons for water leakage or seepage are as follows:

[0028] 1) The concrete surface of the waterstop is uneven. Although there is putty mater...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com