Existing line railway tunnel defect comprehensive improvement operation trolley

A tunnel disease and operation platform technology, which is applied in the field of comprehensive treatment of existing railway tunnel diseases, can solve the problems of low efficiency, time occupied by skylights, and high work intensity of workers, so as to improve the working environment, ensure the working space, and shorten the working time. The effect of placement time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

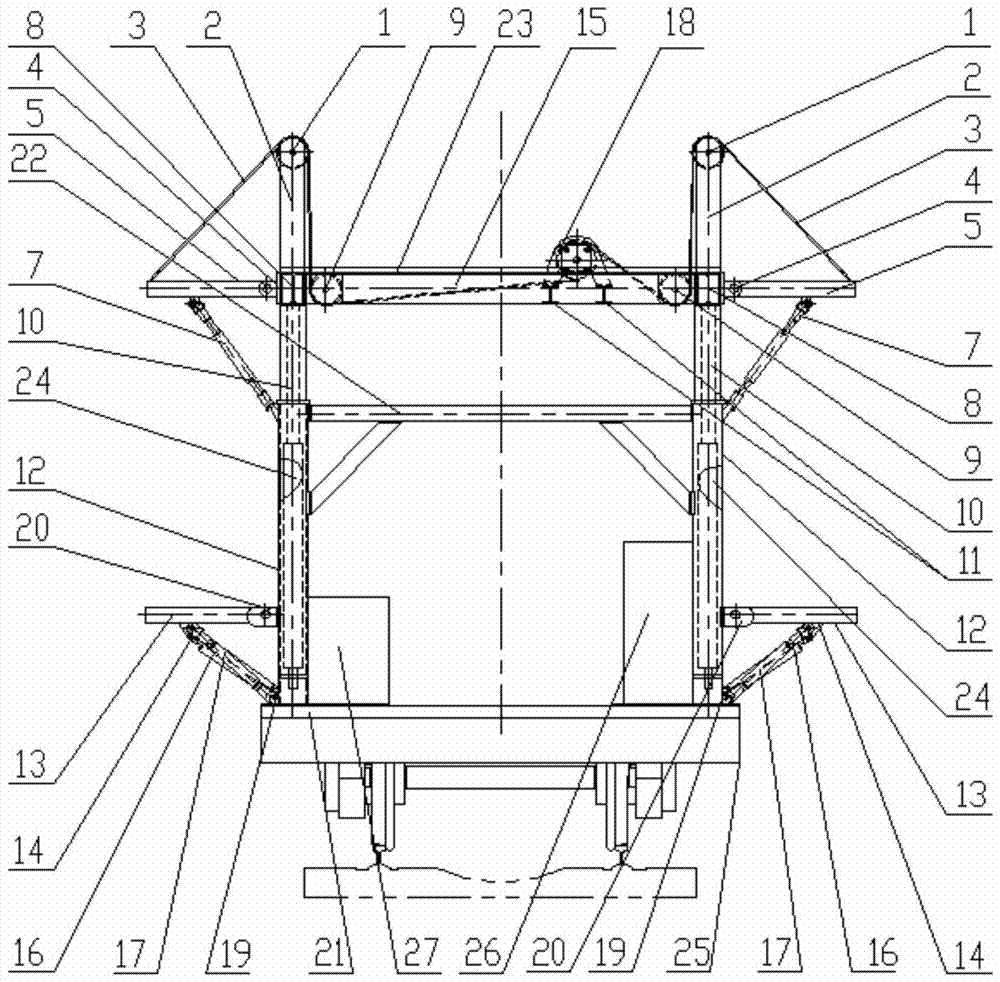

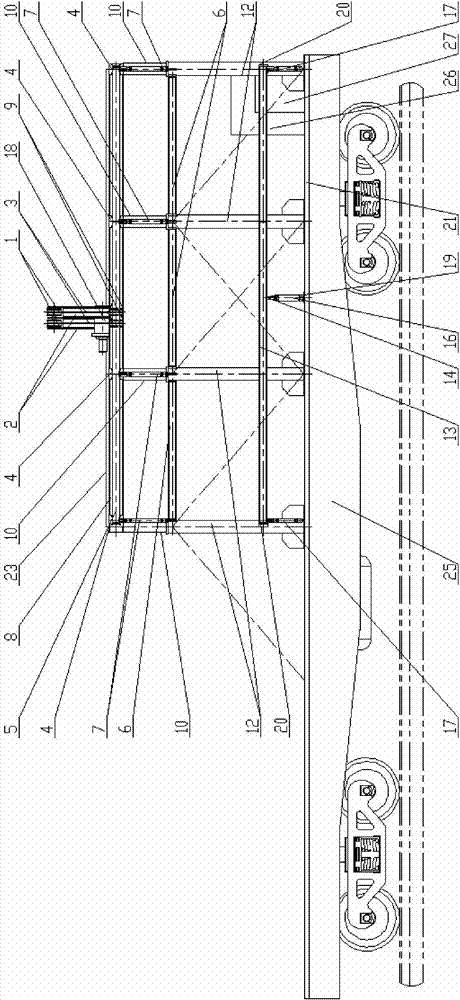

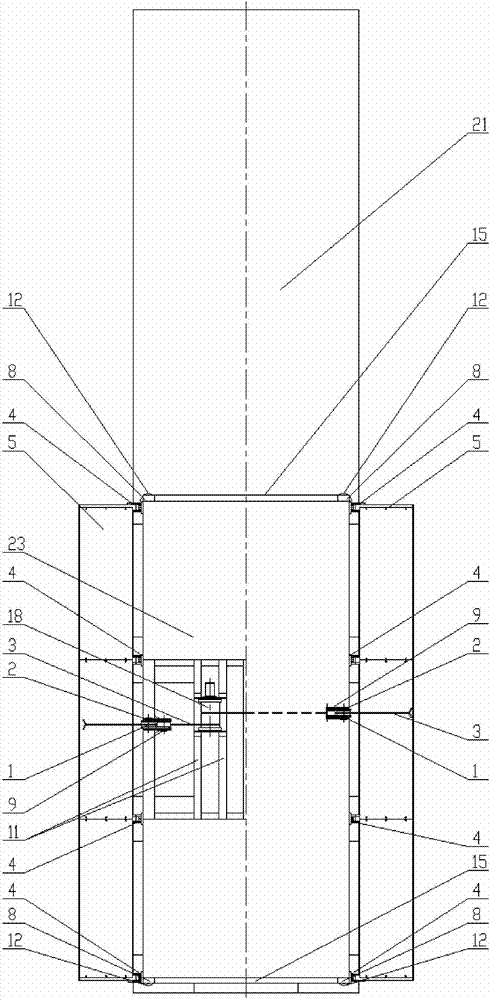

[0018] see Figure 1-6 , the composition of the trolley for the comprehensive improvement of the existing line railway tunnel disease includes a running mechanism 25, a fixed stand fixed on the running mechanism 25, a lift-type top floor operation platform arranged on the fixed stand, and a turning-type top-floor operation platform with a turning mechanism. The lower operating platform is composed of a retractable upper operating platform with a retractable mechanism, wherein the fixed platform is composed of an installation platform 21 installed on the running mechanism 25, and columns 12 symmetrically fixed on both sides of the installation platform 21 1. The lower longitudinal beam 6 connected to the upper end of each column 12 and the lower cross arm 22 constitute. The lift-type roof work platform is composed of a guide sleeve 10 installed inside the column 12, a lifting hydraulic cylinder 24 hinged between the guide sleeve 10 and the column 12, and an upper longitudinal b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com