Coordinated deformation anchoring device for full-length anchoring support

An anchoring device and full-length anchoring technology, applied in the installation of bolts, mining equipment, earth-moving drilling, etc., can solve the problems of uneven stress distribution, uneven stress on the bolts, slippage, etc., to avoid small deformation, High practical value and improved control effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The present invention will be further described below in conjunction with the accompanying drawings.

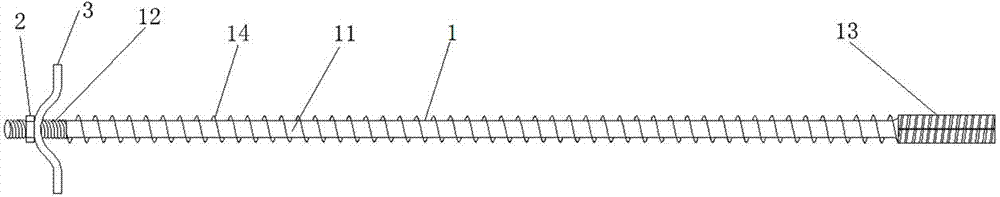

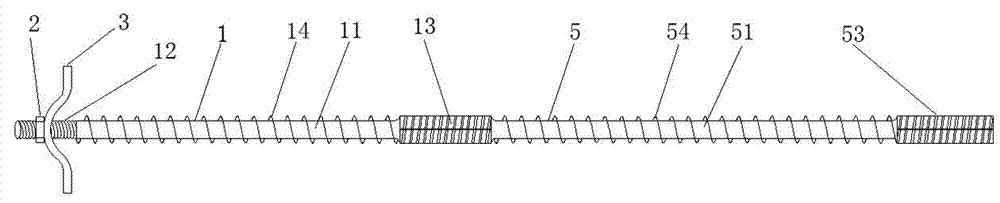

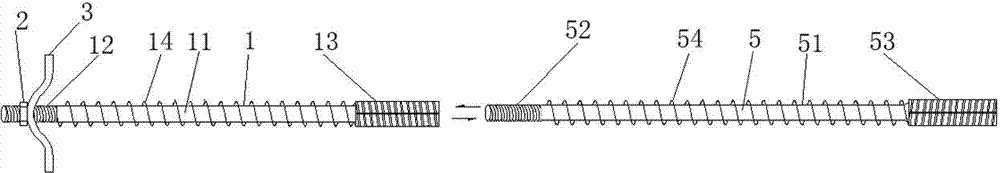

[0013] figure 1 Shown is an embodiment of the present invention, comprises anchor rod 1, backing plate 3 and nut 2, and described anchor rod 1 comprises external thread end 12, rod body portion 11 and threaded steel end 13, and described external The threaded end 12 and the threaded steel end 13 are located at the rear end and the front end of the rod body 11 respectively. The rod body 11 is covered with a coil 14 made of a spring or a steel strand, and the coil 14 made of a spring or a steel strand The two ends of 14 are welded on the rod body, the backing plate 3 is sleeved on the external thread end 12, the nut 2 is connected with the external thread of the external thread end 12, and is positioned at the back of the backing plate 3 for fixing the backing plate 3. The diameter of the coil 14 made of spring or steel strand is larger than the diameter of the rod ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com