A bolt fastening force state indicating washer

A state indication and tightening force technology, applied in the installation of bolts, mining devices, mining equipment, etc., can solve the problems of inability to indicate and detect the bolt tightening force status, and achieve low installation torque, high preload, The effect of eliminating end-face friction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

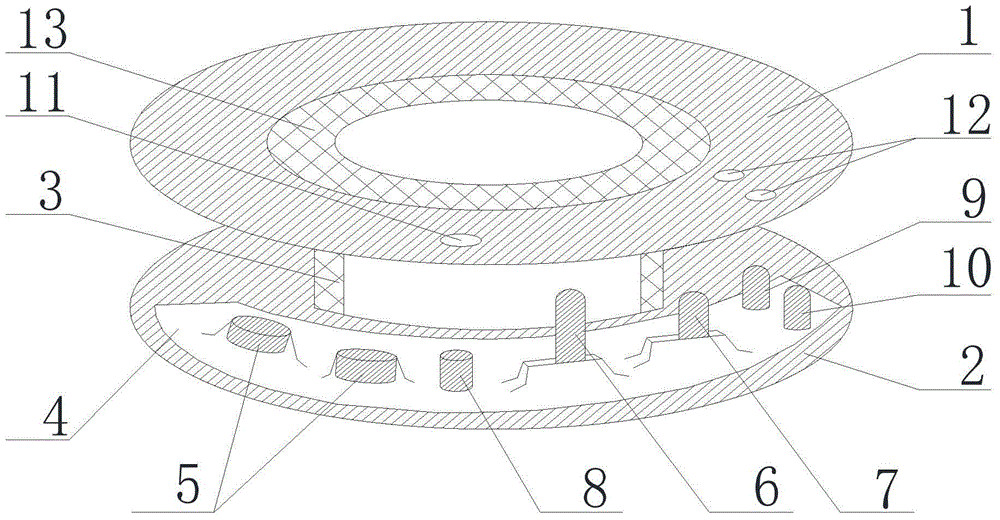

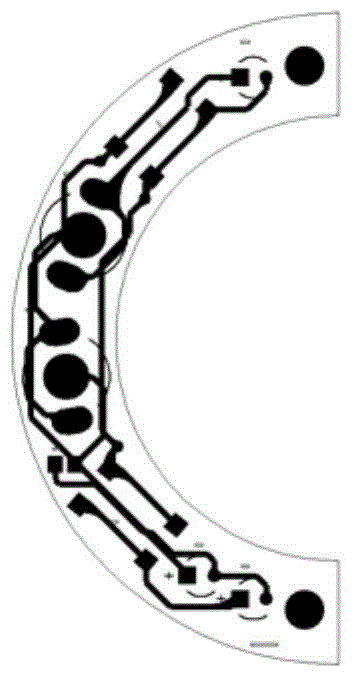

[0031] Such as Figure 1~3 As mentioned above, the present invention includes a deformation unit and an electric control unit. The deformation unit includes an upper extruding body 1, a lower extruding body 2 and a pressure bearing body 3; The indicating device, the anchor breaking warning indicating device and the power supply 5; The circuit board 4 is fixedly installed on the lower extrusion body 2 by screws.

Embodiment 2

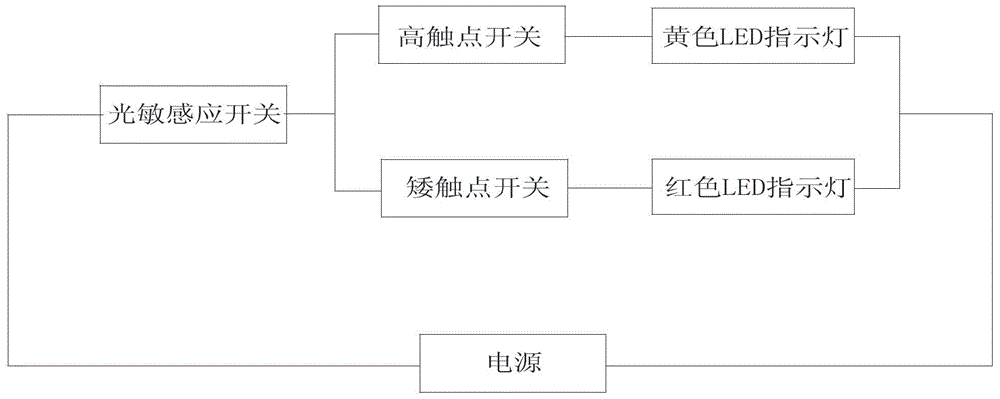

[0033] Such as Figure 1~3As mentioned above, the present invention includes a deformation unit and an electric control unit. The deformation unit includes an upper extruding body 1, a lower extruding body 2 and a pressure bearing body 3; The indicating device, the anchor breaking warning indicating device and the power supply 5; The pretightening force standard indicating device includes a high contact switch 6 and a yellow LED indicator light 9, and the anchor breakage warning indicating device includes a short contact switch 7 and a red LED indicator light 10; the high contact switch 6 and the short contact switch 7 respectively Control yellow LED indicator light 9 and red LED indicator light 10. The power supply 5 is specifically a button battery. The circuit board 4 is fixedly installed on the lower extrusion body 2 by strong glue; the high contact switch 6 and the short contact switch 7 are fixedly installed on the circuit board 4 by screws; the high contact switch 6 i...

Embodiment 3

[0040] Such as Figure 1~3 As mentioned above, the present invention includes a deformation unit and an electric control unit. The deformation unit includes an upper extruding body 1, a lower extruding body 2 and a pressure bearing body 3; The indicating device, the anchor breaking warning indicating device and the power supply 5; The pretightening force standard indicating device includes a high contact switch 6 and a yellow LED indicator light 9, and the anchor breakage warning indicating device includes a short contact switch 7 and a red LED indicator light 10; the high contact switch 6 and the short contact switch 7 respectively Control yellow LED indicator light 9 and red LED indicator light 10. The power source 5 is specifically a storage battery. The circuit board 4 is fixedly installed on the lower extrusion body 2 by screws and strong glue; the high contact switch 6 and the short contact switch 7 are fixedly installed on the circuit board 4 by strong glue; the high ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com