Swing type isolating device for coal mine paste filling exploitation and isolating method

An isolation device and paste filling technology, which is applied in the direction of fillings, safety devices, mining equipment, etc., can solve the problem of isolation of the area to be filled, and achieve the effects of improving work efficiency, ensuring the effect of filling and isolation, and shortening the working time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] Embodiment 1: A swing type isolation device and isolation method, used for isolation operation of the area to be filled, the technical solution is as follows:

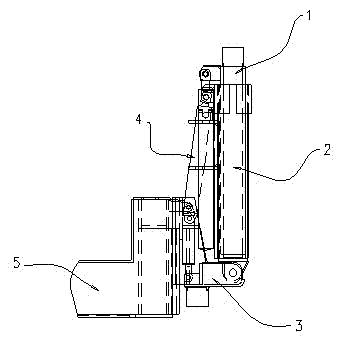

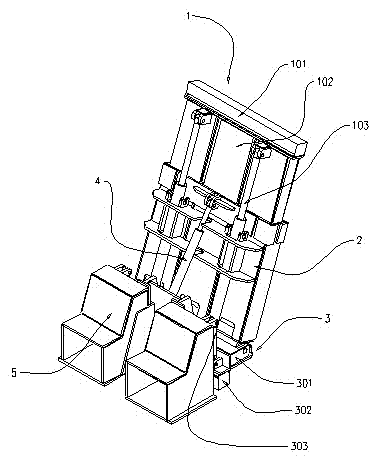

[0029] The filling and isolating device includes: a telescopic mechanism 1, an isolating plate 2, a lifting mechanism 3, a swing jack 4 and a support base 5; one end of the telescopic mechanism 1 is hinged with one end of the lifting mechanism 3, and the other end of the lifting mechanism 3 is connected to the support On the base 5, a swing jack 4 is connected between the other end of the telescopic mechanism 1 and the support base 5, and the rear of the support base 5 has a slideway.

[0030] The telescopic mechanism 1 includes: a top sealing strip 101, a telescopic box 102, and a telescopic jack 103; the top sealing strip 101 is installed on the top of the telescopic box 102; the telescopic box 102 is installed in the isolation plate 2; one end of the telescopic jack 103 It is hinged with the isolation board 2, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com