Packaging box shock attenuation system for transportation working condition changes of spacecraft

A vibration reduction system and technology for transport workers, which are applied in the directions of transportation and packaging, shock absorbers, gas shock absorbers, etc., can solve the problem that the vibration reduction system of the packaging box cannot be satisfied at the same time, and achieve fast mode switching and realize mode switching. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The following is a specific implementation manner of the content of the present invention, and the content of the present invention will be further clarified through the specific implementation mode below. Of course, the following specific embodiments are described only to illustrate different aspects of the present invention, and should not be construed as limiting the scope of the present invention.

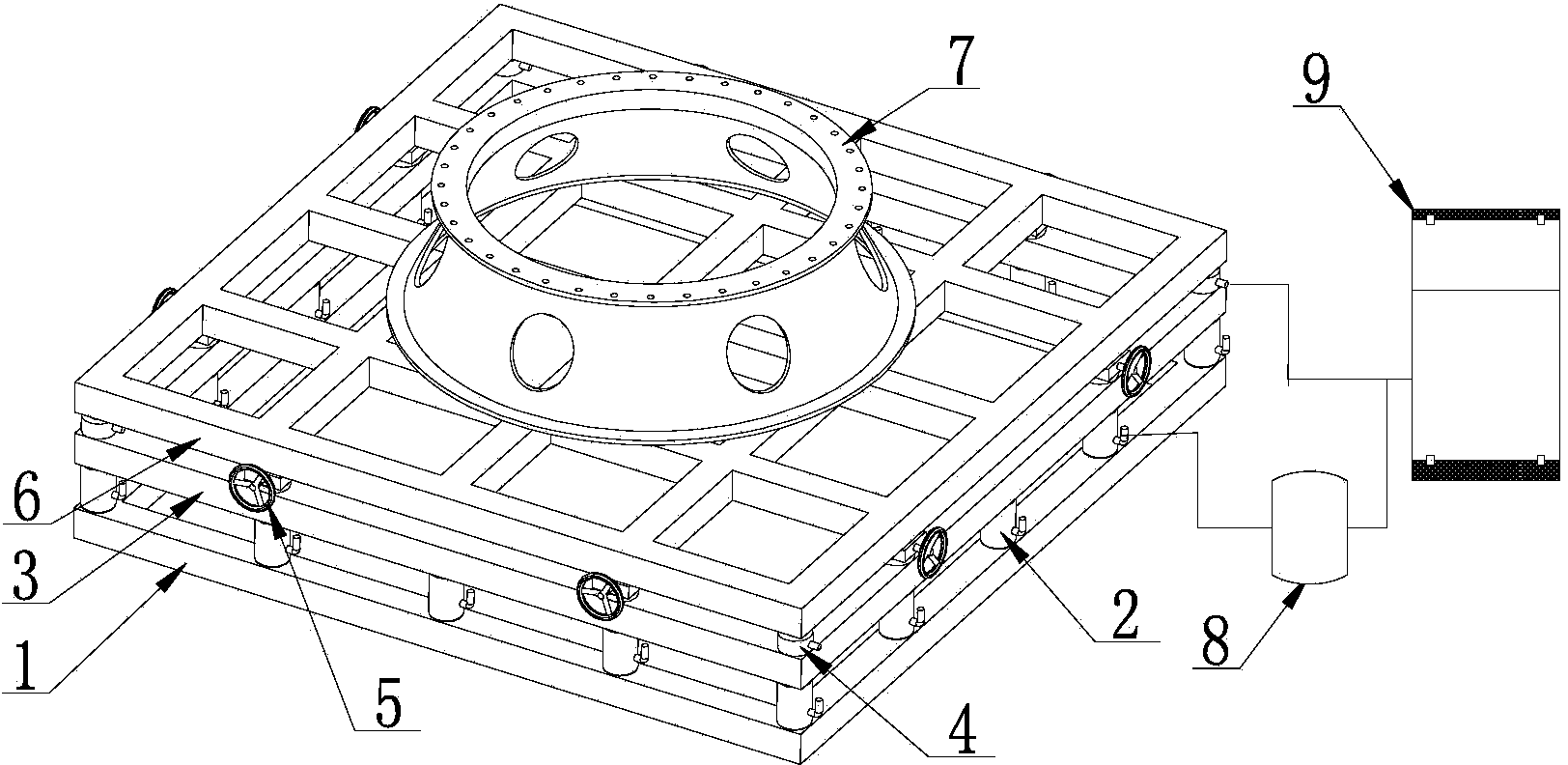

[0023] Such as figure 1 As shown, the packaging box vibration damping system for changing the transportation condition of the spacecraft of the present invention mainly includes a lower bottom plate 1, a middle plate 3, an upper frame 6, an air spring 2, a load cell 4, a support device 5, and an adapter 7 , the control device 9 and the inflation device 8, the lower base plate 1 supports the middle plate 3 through a plurality of air springs 2, the middle plate 3 supports the upper frame 6 through a plurality of supporting devices or more than three load cells 4, and the u...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com