Gear shift control system for automatic transmission

A technology of automatic transmission and control system, applied in transmission control, motor vehicles, hybrid vehicles, etc., can solve problems such as lack of braking force, and achieve the effect of promoting ease, low cost, and improving accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

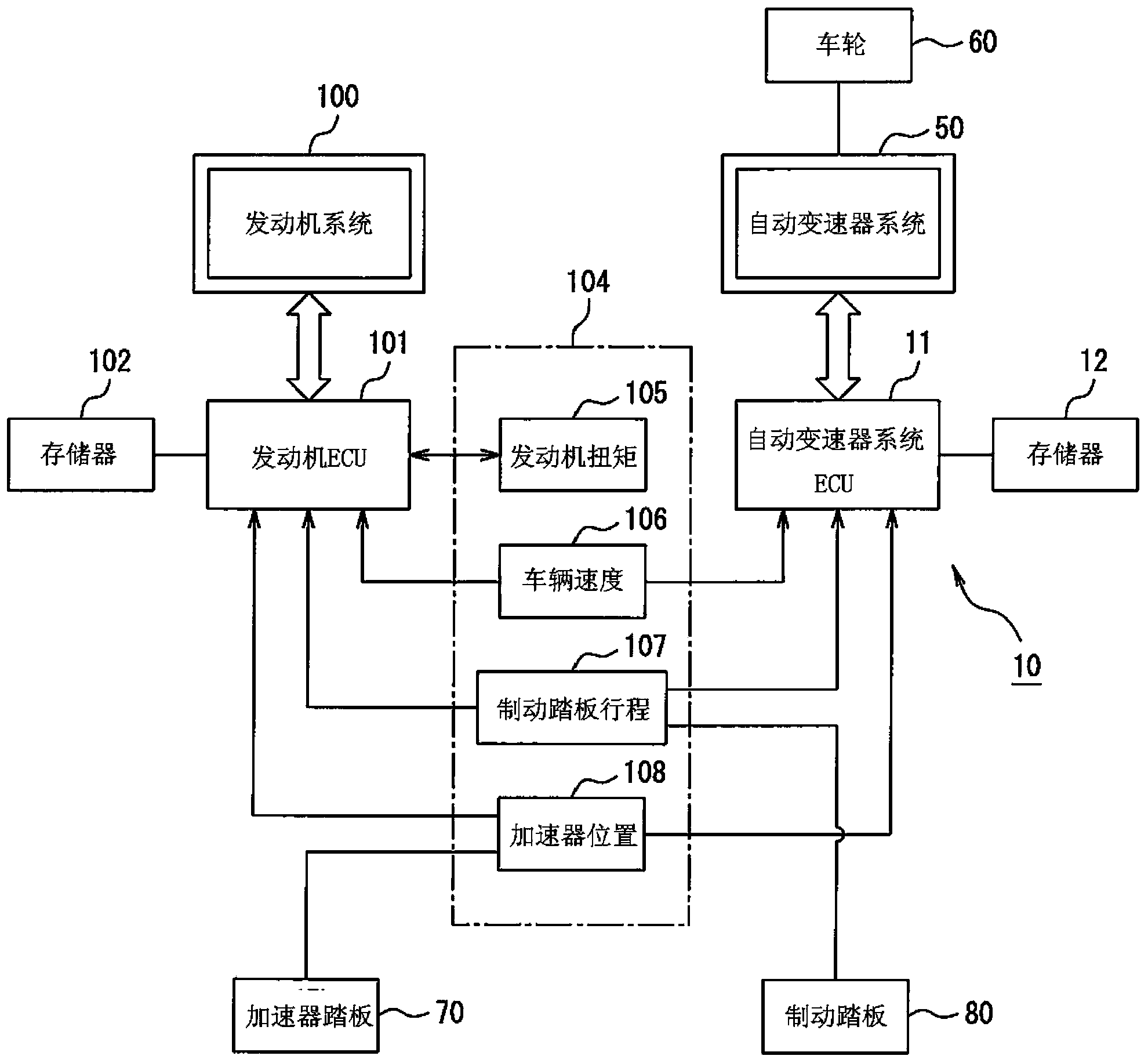

[0039] Embodiments will be described below with reference to the drawings. Figure 1 to Figure 7 The shift control system 10 of the automatic transmission according to the first embodiment will be described.

[0040] The transmission control system 10 is designed to control the operation of an automatic transmission mounted on a motor vehicle together with an internal combustion engine. The automatic transmission automatically changes the speed of the drive shaft of the internal combustion engine and transmits the torque of the drive shaft to the transaxle of the wheels 60 to drive the vehicle.

[0041] The internal combustion engine referred to herein is configured to combust a mixture of air and fuel injected into a combustion chamber to reciprocate a piston, thereby rotating a drive shaft through a crankshaft to output torque. Operation of an engine system 100 including an internal combustion engine and components or actuators such as fuel injectors is generally controlled...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com