Light source device

A technology of light source device and light guide body, which is applied in the direction of light source, electric light source, printing device, etc., which can solve the problems of high-illuminance lighting area, poor balance of illuminance distribution, inability to form cross-sectional light distribution uniformity, etc., and achieve easy manufacturing , High uniformity of illuminance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

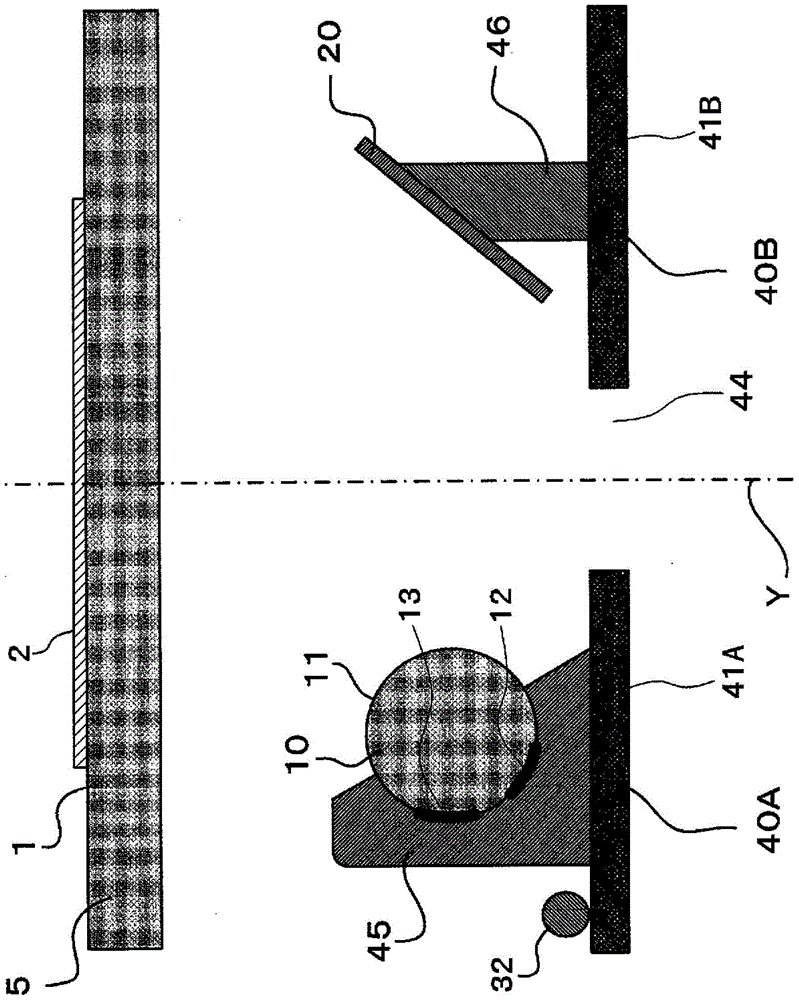

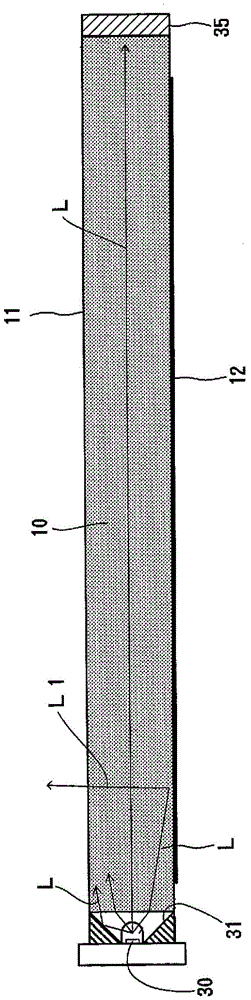

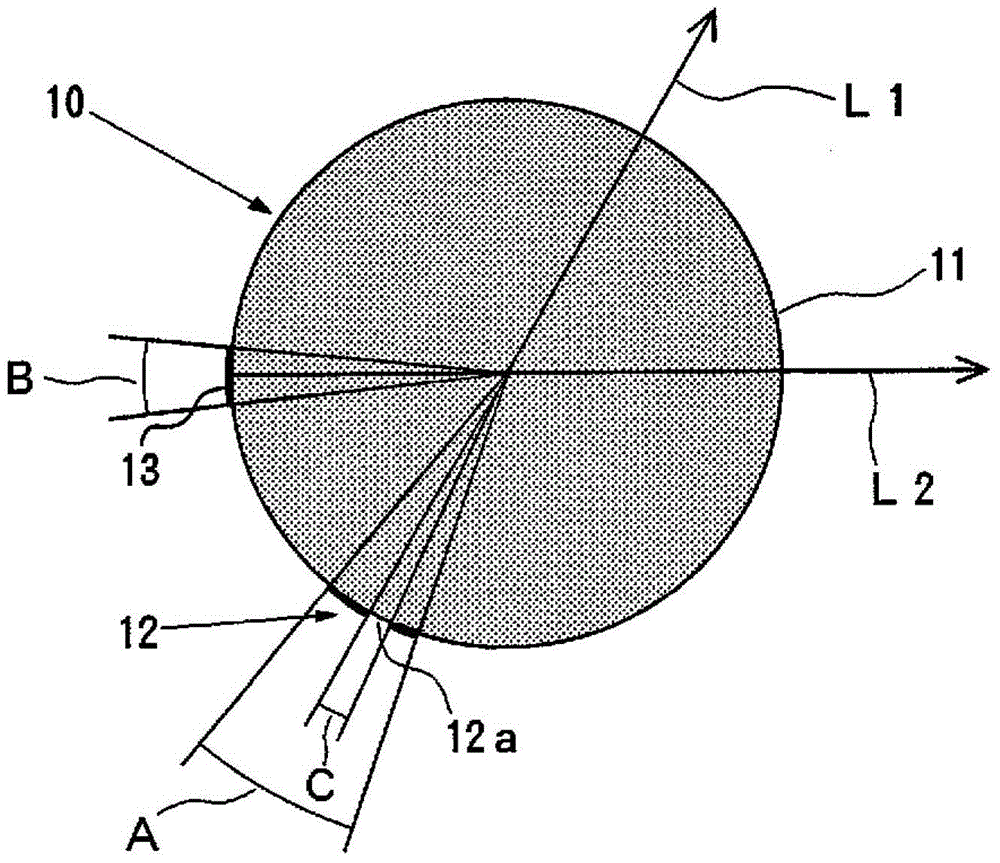

[0084] Using a white LED element as the LED element, and under the following conditions, a figure 1 The structure of the light source device (A) is shown.

[0085]The material of the light guide is acrylic resin, the overall length is 340mm, and the diameter is 5mm. The first reflective part and the second reflective part of the light guide are constituted by a plurality of concave parts arranged along the longitudinal direction of the light guide. The depth of the above-mentioned concave part is 0.05 mm, the width of the above-mentioned concave part in the longitudinal direction of the light guide body 10 is 0.2 mm, and the separation distance between adjacent concave parts is: the indirect light side is separated by 0.4 mm to 0.6 mm in the longitudinal direction , the direct light side is separated by 0.7mm to 1.0mm in the length direction (the spacing of the concave parts is: the indirect light side is 0.6mm to 0.8mm in the length direction, and the direct light side is 0...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Depth | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com